Prefabricated laminated component and rough surface forming device

A molding device and a technology for stacking components, which are used in building components, ceramic molding machines, auxiliary molding equipment, etc., can solve problems such as irregularities in rough surface structure, and achieve the effects of improving construction quality, improving work efficiency, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

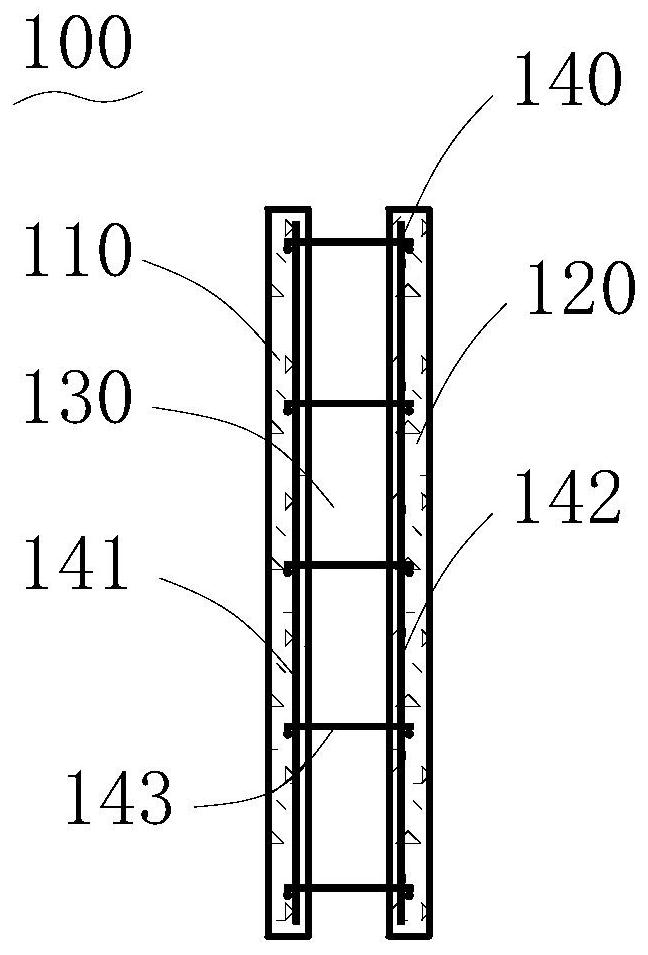

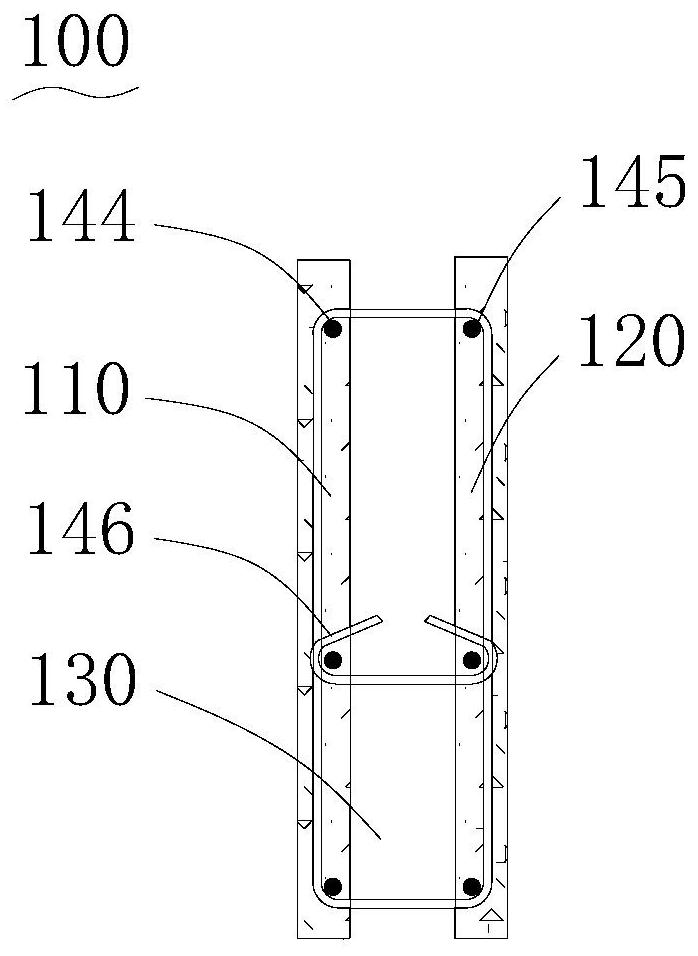

[0055] combine Figure 1-Figure 2 As shown, the prefabricated composite components provided in this embodiment include:

[0056] the first vane 110;

[0057] The second leaf plate 120 is arranged opposite to the first leaf plate 110;

[0058] The connection assembly 140 is arranged between the first leaf plate 110 and the second leaf plate 120 and is suitable for connecting the first leaf plate 110 and the second leaf plate 120;

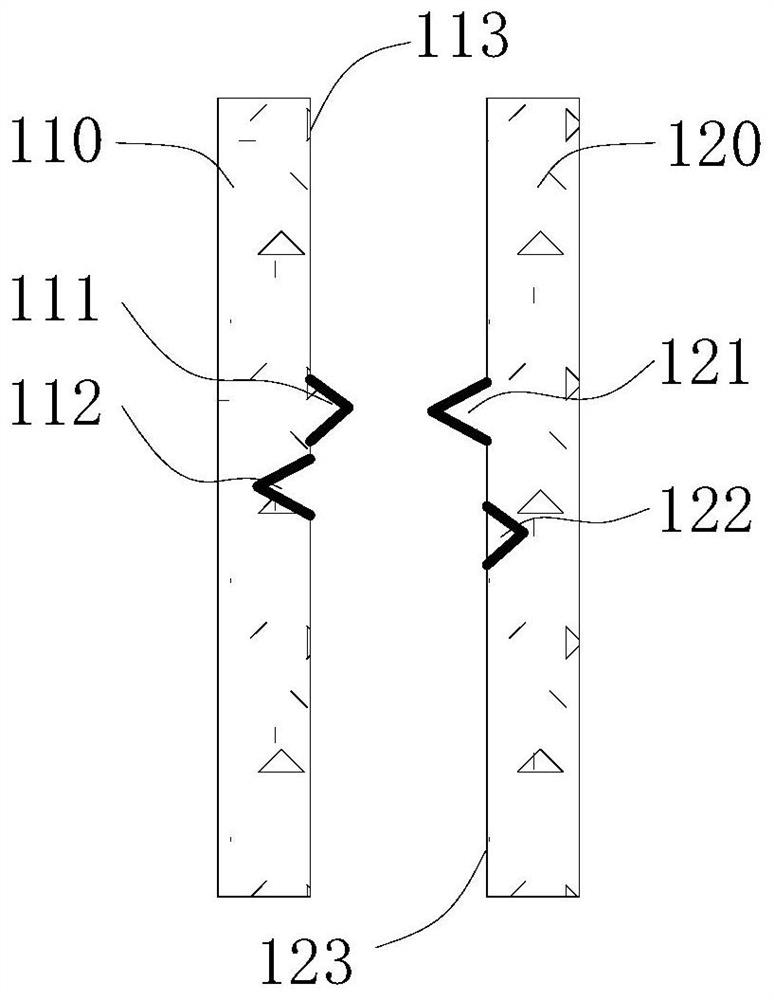

[0059] A cavity 130 is formed between the first blade 110 and the second blade 120 , the first inner surface 113 of the first blade 110 facing the cavity 130 includes a first protrusion 111 , The second inner surface 123 of the second vane 120 facing the cavity 130 includes a second protrusion 121 , and the first protrusion 111 is opposite to the second protrusion 121 alternately;

[0060] And / or, the first vane 110 includes a first recess 112 towards the first inner surface 113 of the cavity 130 , and the second vane 120 includes a second inner s...

Embodiment 2

[0073] combine Figure 1-Figure 11 As shown, the present embodiment provides a rough surface forming device, comprising:

[0074] The supporting part 220 is adapted to abut against the second inner surface 123 of the above-mentioned prefabricated laminated component, and is adapted to move along the second inner surface 123;

[0075] The forming part 210 is arranged opposite to the support part 220 and is fixedly connected with the support part 220, and is suitable for forming the first inner surface of the prefabricated laminated component as described above as the support part 220 moves. 113.

[0076] Preferably, the second inner surface 123 is a formed relatively completely solidified surface, which can ensure the abutment of the support portion 220, and the second inner surface 123 is provided with a formed second raised portion 121 and / or the second concave portion 122, the support portion 220 moves along the direction of the second raised portion 121 and / or the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com