Ultra-supercritical safety valve test platform under actual working condition

An ultra-supercritical, test platform technology, applied in the direction of mechanical valve testing, etc., can solve the problem that the pressure and temperature parameters cannot meet the test requirements of the thermal performance of ultra-supercritical safety valves, and achieve the effect of improving the inspection ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

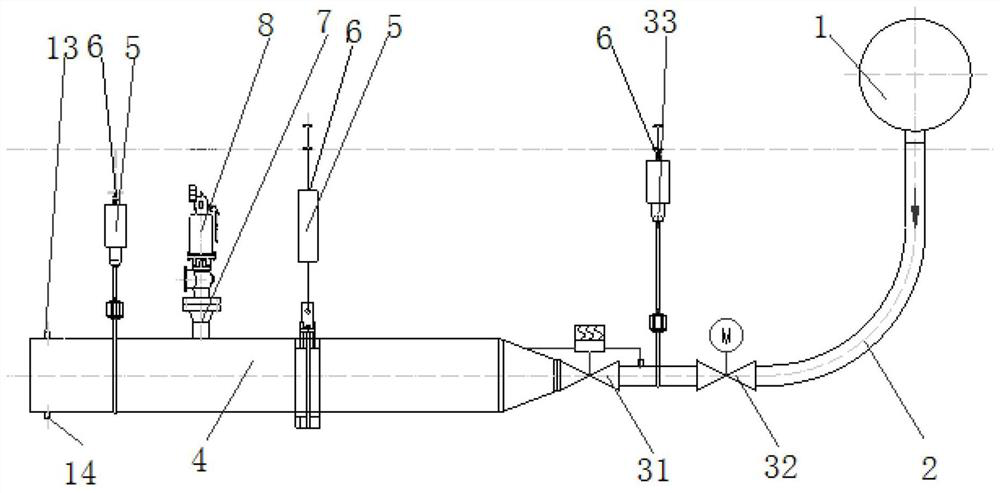

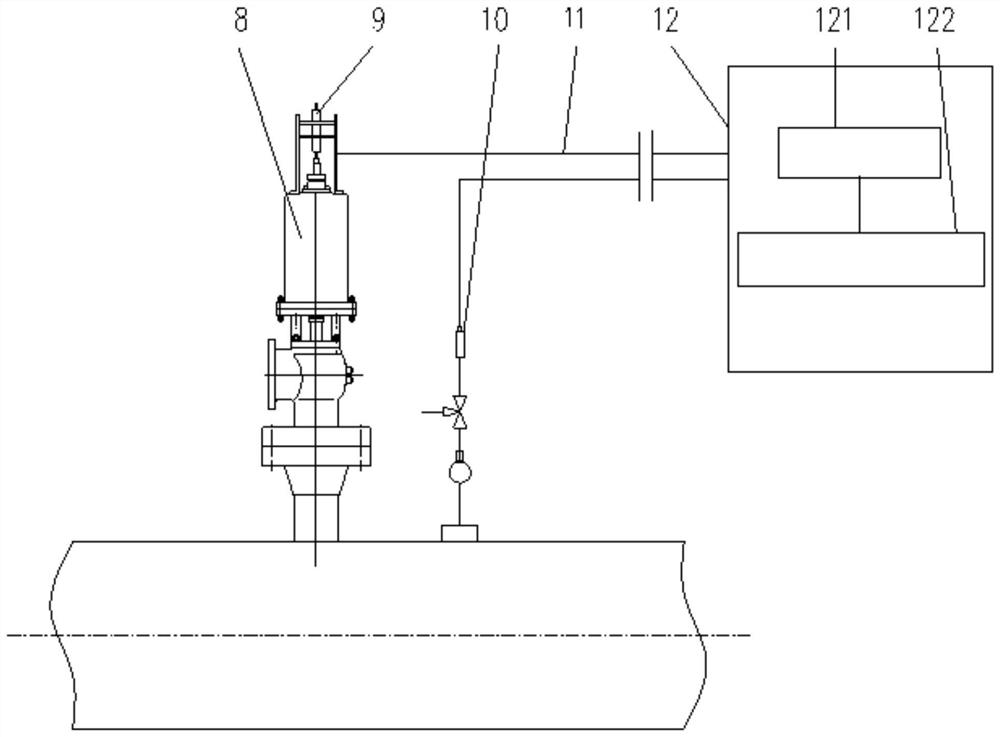

[0021] The invention provides an ultra-supercritical safety valve test platform under actual working conditions, the test platform includes an intake pipe 2; one end of the intake pipe 2 is connected to the main steam pipeline of a 660MW ultra-supercritical generating set 1, and the other end It is connected with the test pipe section 4; the middle part of the test pipe section 4 is provided with a safety valve test pipe seat 7, and a safety valve 8 is provided above the safety valve test pipe seat 7; an electric gate valve 32 is provided on the air intake pipe 2.

[0022] A first hanging device 33 is arranged on the air intake pipe 5 , and a damper 6 is arranged on the first hanging device 33 .

[0023] A second hanging device 5 is arranged on the test pipe section 4, and a damper 6 is arranged on the second hanging device 5.

[0024] A defla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com