Automatic hydrostatic test device for boiler tube panel and working method of automatic hydrostatic test device

A hydrostatic test and automatic water supply technology, which is applied to measuring devices, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of high pressure of boiler tube panel hydrostatic test, hidden dangers of manual operation, and insufficient plugging. Reliability and other issues, to achieve efficient hydraulic test inspection, save manpower and material resources, and eliminate potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with accompanying drawing, and its content is explanation of the present invention rather than limitation:

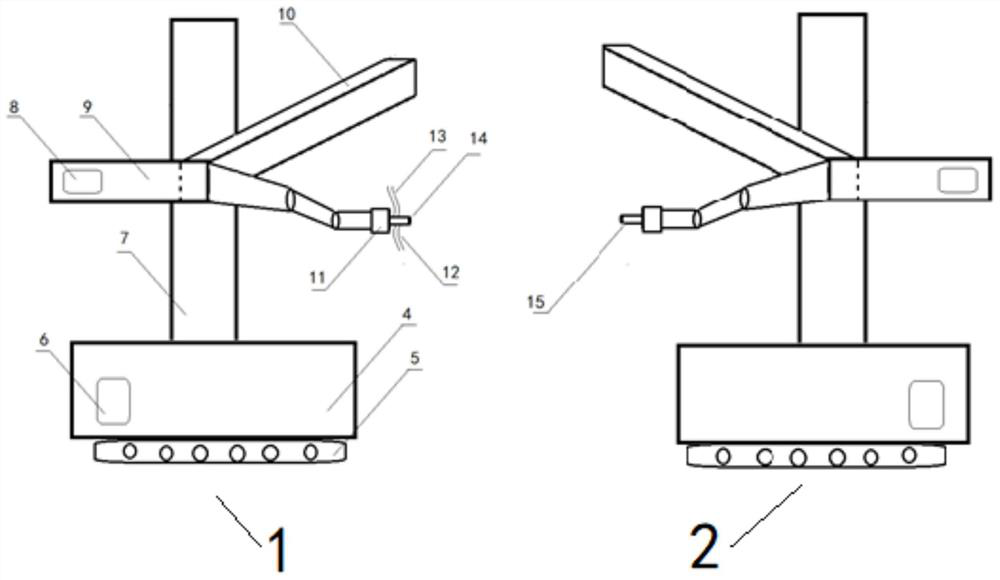

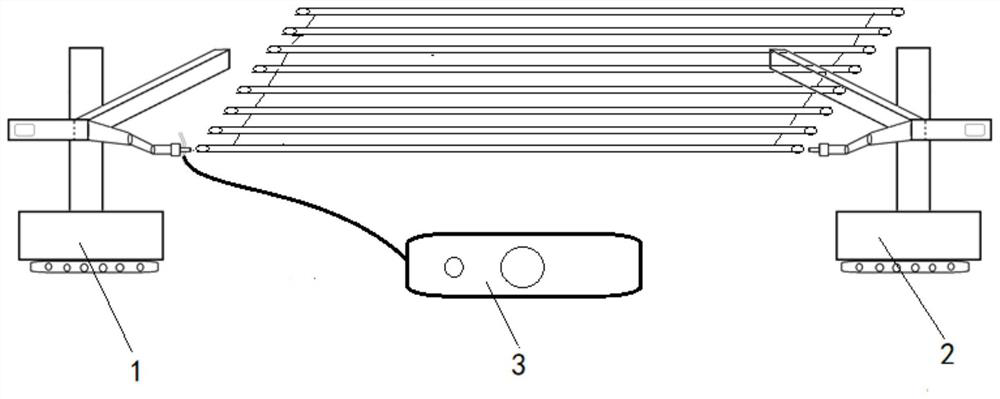

[0031] Such as figure 1 , is boiler tube screen automatic water pressure testing device of the present invention, comprises automatic water supply machine 1, automatic sealing machine 2 and electric pressure test pump 3; Automatic water supply machine 1 and automatic sealing machine 2 all comprise base 4, power Device 5, movable support assembly, mechanical arm 9, nozzle tracking and positioning device 11 and power module 6; The bracket assembly is movably connected with the mechanical arm 9, and the nozzle tracking and positioning device 11 is arranged on the mechanical arm 9; the structure and connection relationship of this part are the same.

[0032] The difference is that the mechanical arm 9 of the automatic water filling machine 1 is connected with a water supply tool 14, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com