Shunt type current measurement compensation method and device

A technology of current measurement and compensation method, which is applied in the direction of measuring devices, only measuring current, measuring electrical variables, etc. It can solve the problem that the look-up table method cannot compensate for the influence of self-heating measurement in real time, the error of the shunt, and the ambient temperature does not represent the shunt, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

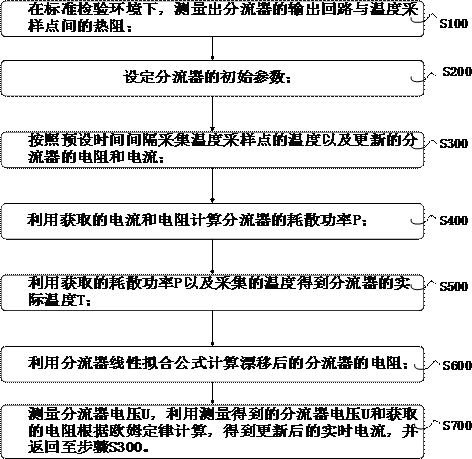

[0066] figure 1 A shunt-type current measurement compensation method is provided for an embodiment of the present invention, comprising the following steps:

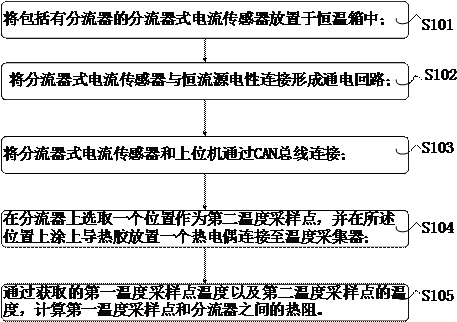

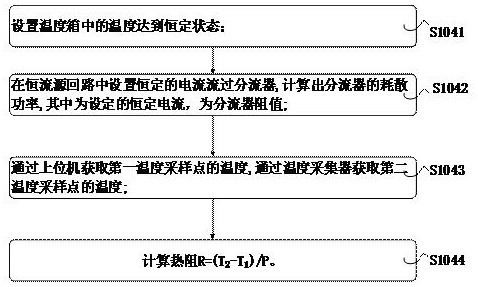

[0067] S100. Under the standard inspection environment, measure the thermal resistance R between the output circuit of the shunt and the first temperature sampling point th ;

[0068] S200. Set the initial parameters of the shunt, the initial parameters specifically include the temperature coefficient k of the shunt,

[0069] shunt at T 0 Resistance at temperature R 0 , the thermal resistance R between the shunt body and the temperature sampling point th Wait;

[0070] S300. Collect the temperature T of the first temperature sampling point according to the preset time interval a and updated points

[0071] The resistance and current of the flowmeter, thereby sampling the temperature, resistance and current through the set preset time interval;

[0072] S400. Calculate the power dissipation P of the shunt by using...

Embodiment 2

[0097] Figure 5 An embodiment of the present invention provides a shunt type current measurement and compensation device, including:

[0098] The measurement module is used to measure the thermal resistance R between the output circuit of the shunt on the PCB circuit board and the first temperature sampling point th , and transmitted to the data acquisition module; the initialization module 1 is used to set the initial parameters of the shunt; the data acquisition module 3 is used to collect the temperature T of the first temperature sampling point according to the preset time interval a And the resistance and current of the updated shunt; the first data calculation module 4 is used to calculate the dissipated power P of the shunt according to the obtained current and resistance; the second data calculation module 5 is used to calculate the dissipated power P according to the obtained multiplied by the thermal resistance R th Get the temperature difference, that is, the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com