Control method for improving aerodynamic stability of shipboard aircraft engine during takeoff

A control method and engine technology, applied in the direction of non-electric variable control, temperature control, control/regulation system, etc., can solve the problems that it is difficult to ensure the stability of the take-off state and thrust demand of carrier-based aircraft at the same time, so as to improve the working stability, Guaranteed thrust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

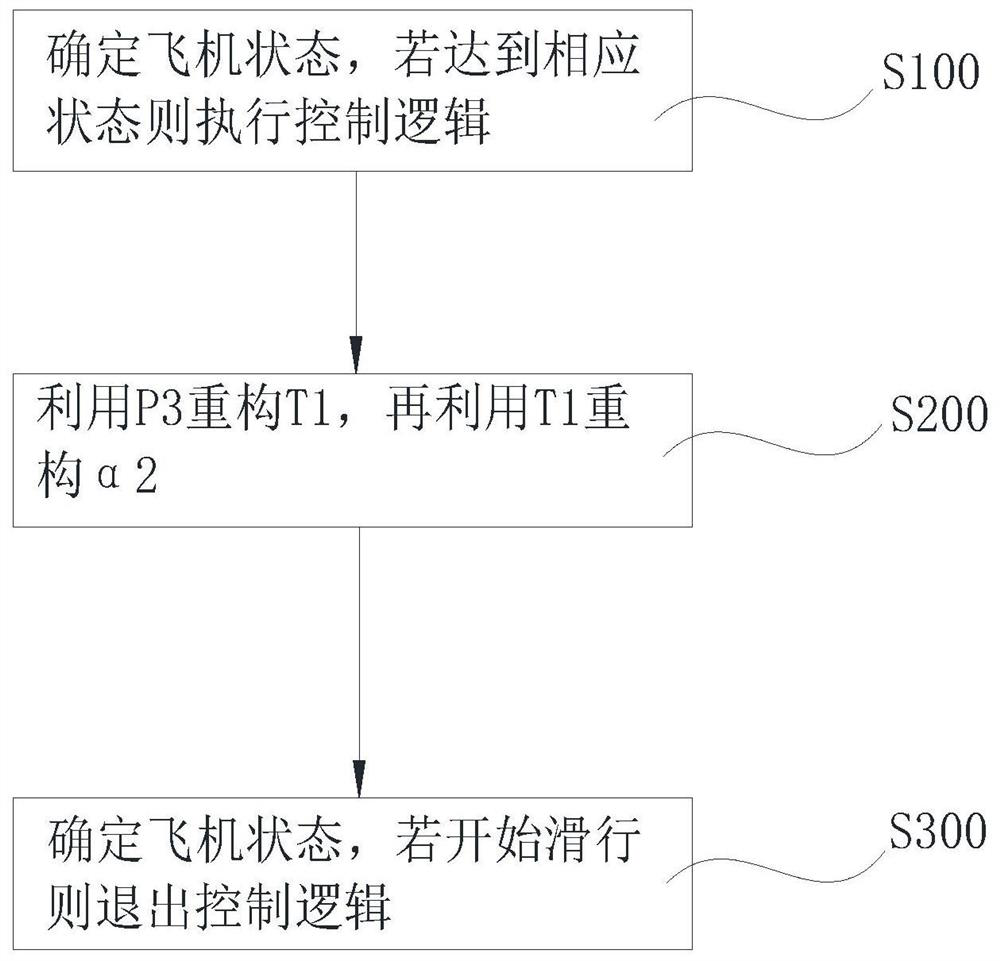

[0046] Embodiment 1, a control method for improving the aerodynamic stability of a carrier-based aircraft engine during take-off, such as figure 1 shown, including,

[0047] Step S100, determine whether the aircraft is on the ground or the fuel oil reaches the maximum state, if so, execute T 1 Refactor the control logic, otherwise do not execute;

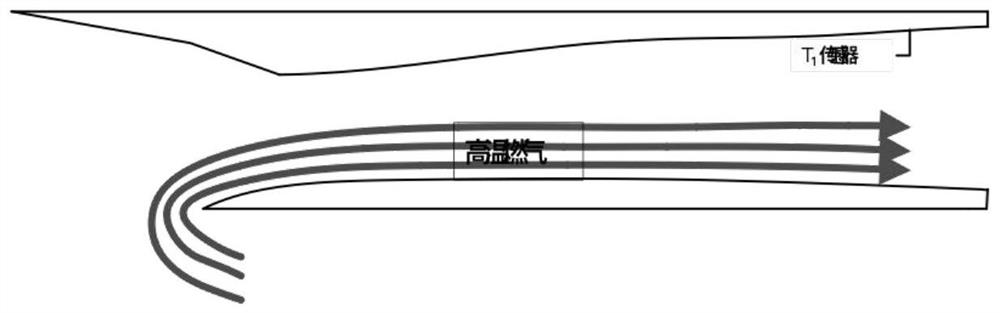

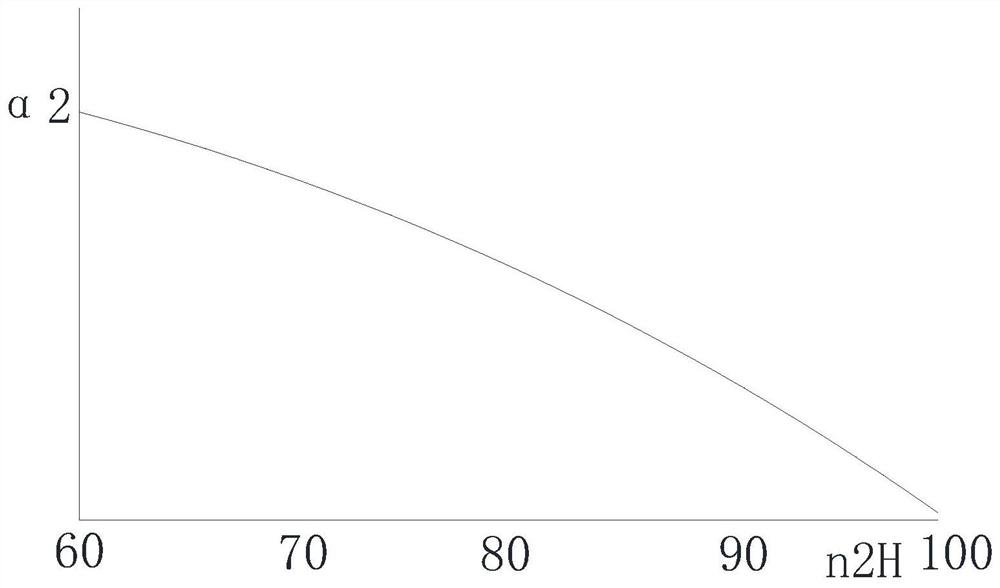

[0048] Step S200, using the engine outlet total pressure P 3 Total inlet temperature T of reconstructed engine 1 , using the reconstructed engine inlet total temperature T 1 Obtain the speed, temperature, afterburner oil, and nozzle control plan values at the maximum state of the engine, and use the reconstructed engine inlet total temperature T 1 Recalculate the relative conversion speed n of the high pressure rotor 2R , use the relative conversion speed n of the high temperature rotor 2R Get the compressor adjustable blade angle α 2 Control plan value to control carrier aircraft;

[0049] Step S300, determine the state o...

Embodiment 2

[0101] Embodiment 2, as a specific implementation, a control system for improving the aerodynamic stability of a carrier-based aircraft engine during take-off, such as Figure 13 As shown, it includes a control logic confirmation module 5 , a control logic execution module 6 , and a control logic exit module 7 .

[0102] The control logic confirmation module 5 is used to determine the state of the aircraft, and when the aircraft is on the ground and the fuel oil reaches the maximum state, execute T 1 Refactoring control logic;

[0103] The control logic execution module 6 is used to utilize the engine outlet total pressure P 3 Total inlet temperature T of reconstructed engine 1 , using the reconstructed engine inlet total temperature T 1 Obtain the speed, temperature, afterburner oil, and nozzle control plan values at the maximum state of the engine, and use the reconstructed engine inlet total temperature T 1 Recalculate the relative conversion speed n of the high press...

Embodiment 3

[0123] Embodiment 3, as a specific implementation, also includes a carrier-based aircraft engine, which includes the control system as described in Embodiment 2. The scheme adopted in the prior art does not consider the thrust of the engine, but uses this system to control The engine can not only ensure the working stability of the engine, but also take into account the performance of the engine thrust during take-off.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com