Method for improving hole-to-hole, line-to-line and line-to-solder mask position precision

A precision and circuit technology, applied in the field of circuit board processing, can solve problems such as the inability to meet the position requirements of automobile boards, and achieve the effect of reducing positioning deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method of improving hole-to-hole location accuracy, the method comprising the steps of

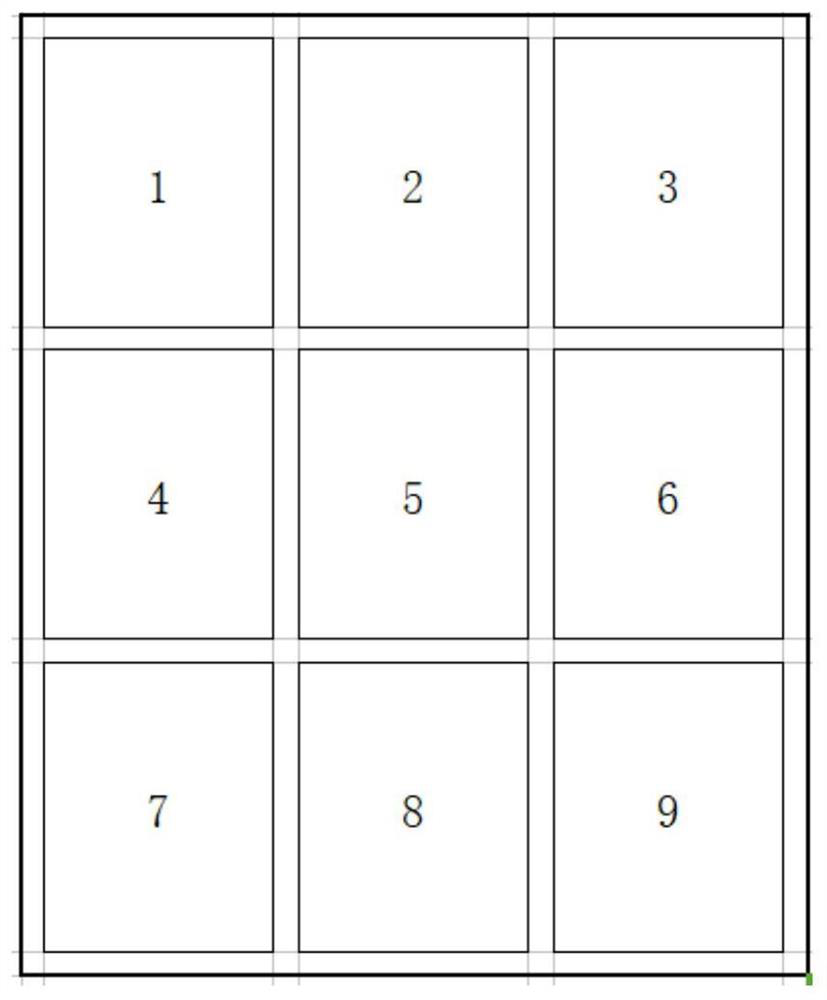

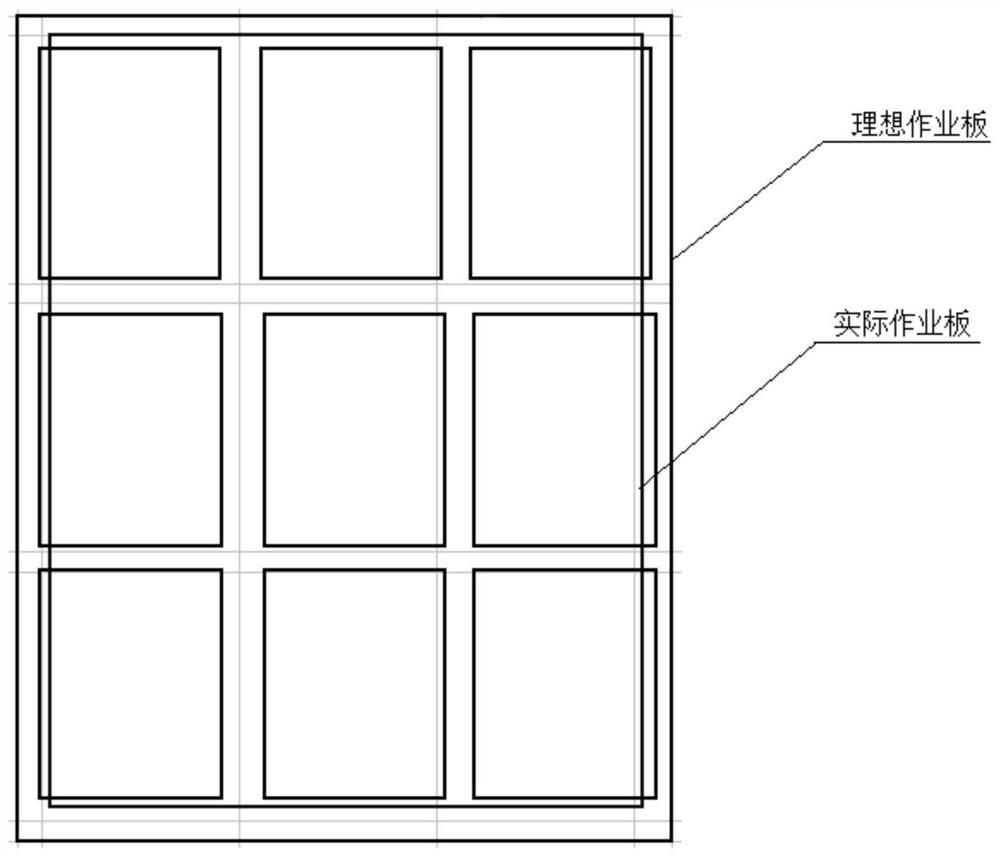

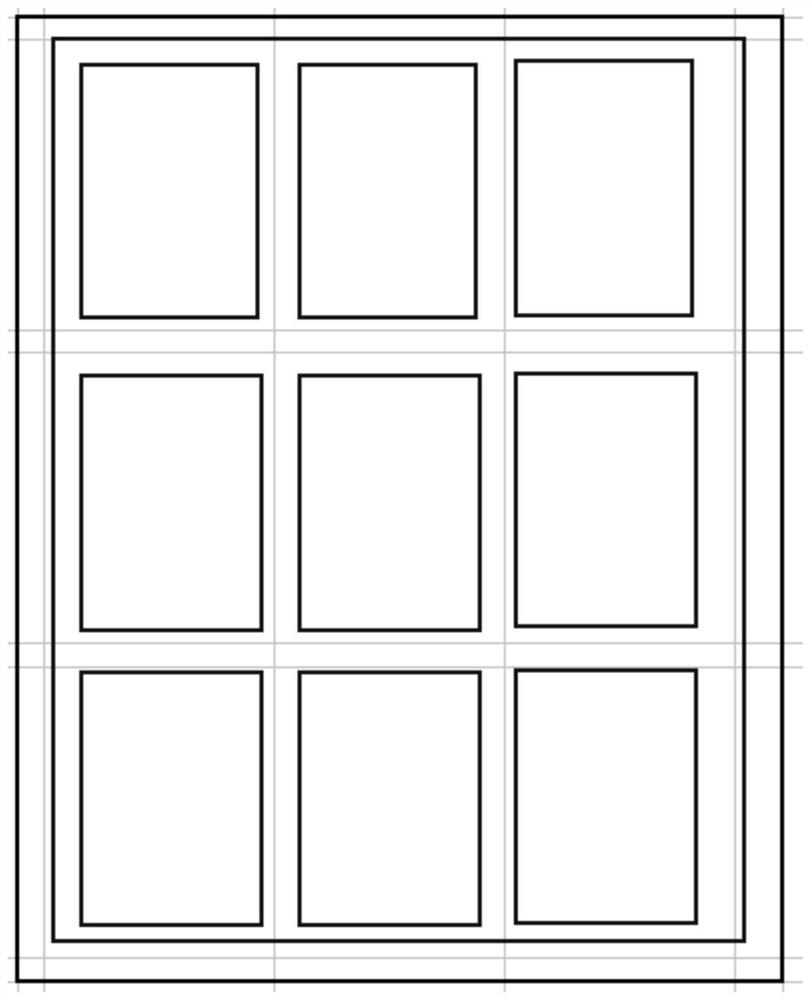

[0030] (1) Design of the work plate: A pre-tension value is given in the work unit of the work plate, and the expansion and contraction of the work plate after pressing is compensated by the translation of the work unit; the pre-tension value in the work unit is used to compensate for the material after heating Deformation, translation of the working unit eliminates fluctuations in compression expansion and contraction between batches in the mass production process.

[0031] (2) Ribbon design: optimize the sequence of gongs and plates, first open the periphery of the working unit, and then drill or drill other holes or grooves in the working unit, so as to release the deformation of different areas on the working plate and disperse it to the following In the positioning system with the working unit as the unit, the error of the positioning of the operating plate is reduced.

[00...

Embodiment 2

[0035] A method of improving line-to-line location accuracy, the method comprising

[0036] Job board design: A pre-tension value is given in the work unit of the job board, and the expansion and contraction of the job board after lamination is compensated by the translation of the work unit; the pre-tension value in the work unit is used to compensate for the deformation of the material after heating, and the work unit The translation eliminates the compression expansion and contraction fluctuation between batches in the mass production process.

[0037] Wherein, the range of the pre-tensioning value is 1%%-3%%.

[0038] Through this step, the line-to-line position capability can be improved to ±0.05mm.

Embodiment 3

[0040] A method of improving the positional accuracy of lines to solder mask, said method comprising

[0041] Job board design: A pre-tension value is given in the work unit of the job board, and the expansion and contraction of the job board after lamination is compensated by the translation of the work unit; the pre-tension value in the work unit is used to compensate for the deformation of the material after heating, and the work unit The translation eliminates the compression expansion and contraction fluctuation between batches in the mass production process.

[0042] Wherein, the range of the pre-tensioning value is 1%%-3%%.

[0043] Through this step, the position capability from the line to the solder mask can be increased to ±0.07mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com