Double-headed output motorized spindle with the ability to eliminate the influence of axial thermal deformation

A technology of electric spindle and thermal deformation, which is applied in the direction of manufacturing tools, large fixed members, metal processing machinery parts, etc. It can solve the problems of less structure of double-head electric spindle, change of bearing preload force, and inability to guarantee the machining accuracy of the spindle, etc., to achieve Good versatility and practical value, eliminating the effect of position accuracy and eliminating the effect of additional thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

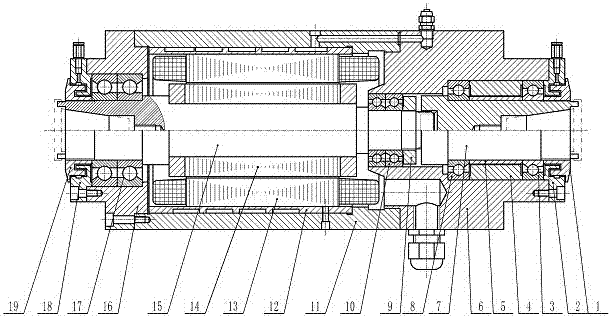

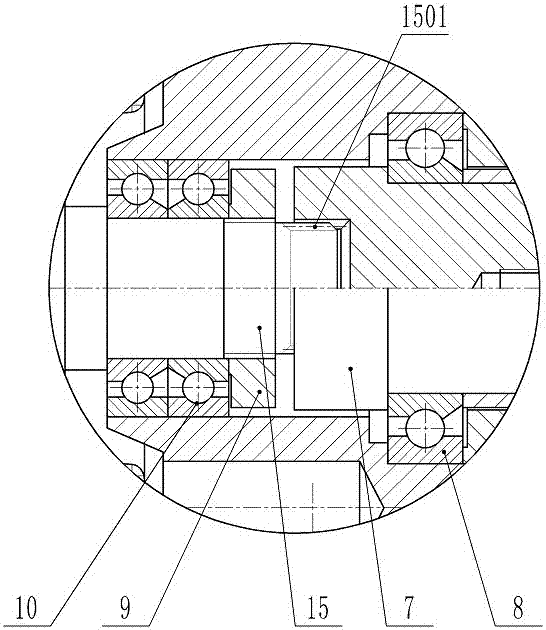

[0017] Such as figure 1 As shown, a double-headed output electric spindle with the ability to eliminate the influence of axial thermal deformation includes an active motor spindle assembly and a driven rotating shaft assembly. The active motor spindle assembly consists of an active rotating shaft 15, a front bearing 17, a rear bearing 10, and a built-in motor stator 13 and built-in motor rotor 14 and front bearing seat 16, housing 11, inner water jacket 12, front cover 18, front nut 19, rear nut 10, driven shaft assembly is composed of driven shaft 7, bearing seat 6, left support Bearing 8, right support bearing 3, back cover 2, lock nut 1 form.

[0018] The two ends of the electric spindle are respectively installed with a driving shaft 15 and a driven shaft 7, and the outer ends of the two shafts are provided with an output tool interface (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com