Personalized adjustable osteotomy guide plate

An adjustable and guide plate technology, applied in bone drill guidance, medical science, surgery, etc., can solve the problems of complex operating mechanical structure, inability to limit the swing saw osteotomy, and the change of the width of the knife groove, so as to improve the accuracy of osteotomy , simple structure, and the effect of precise adjustment ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

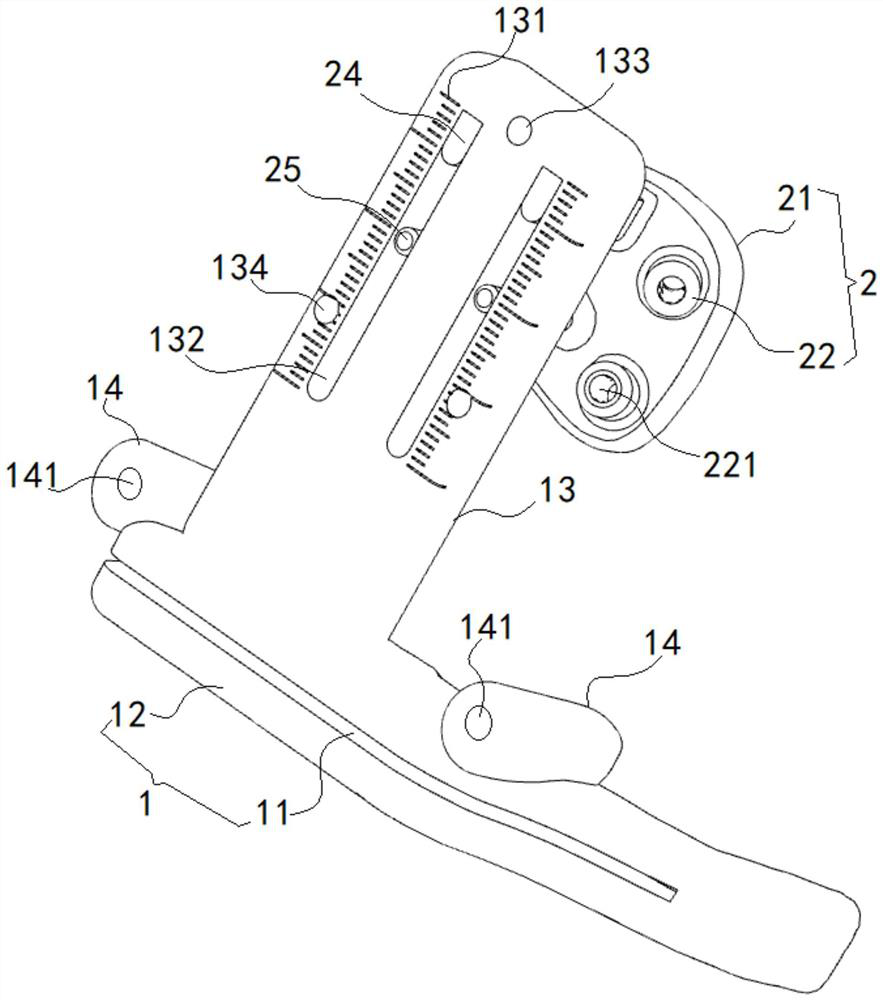

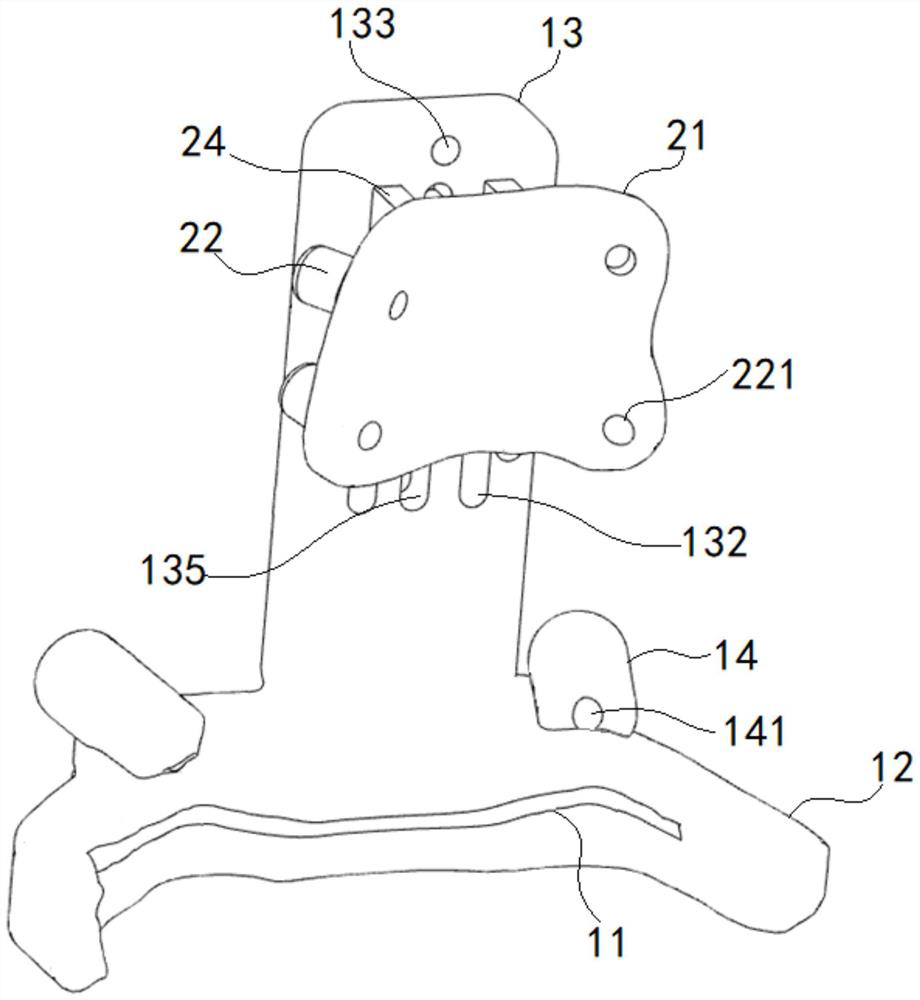

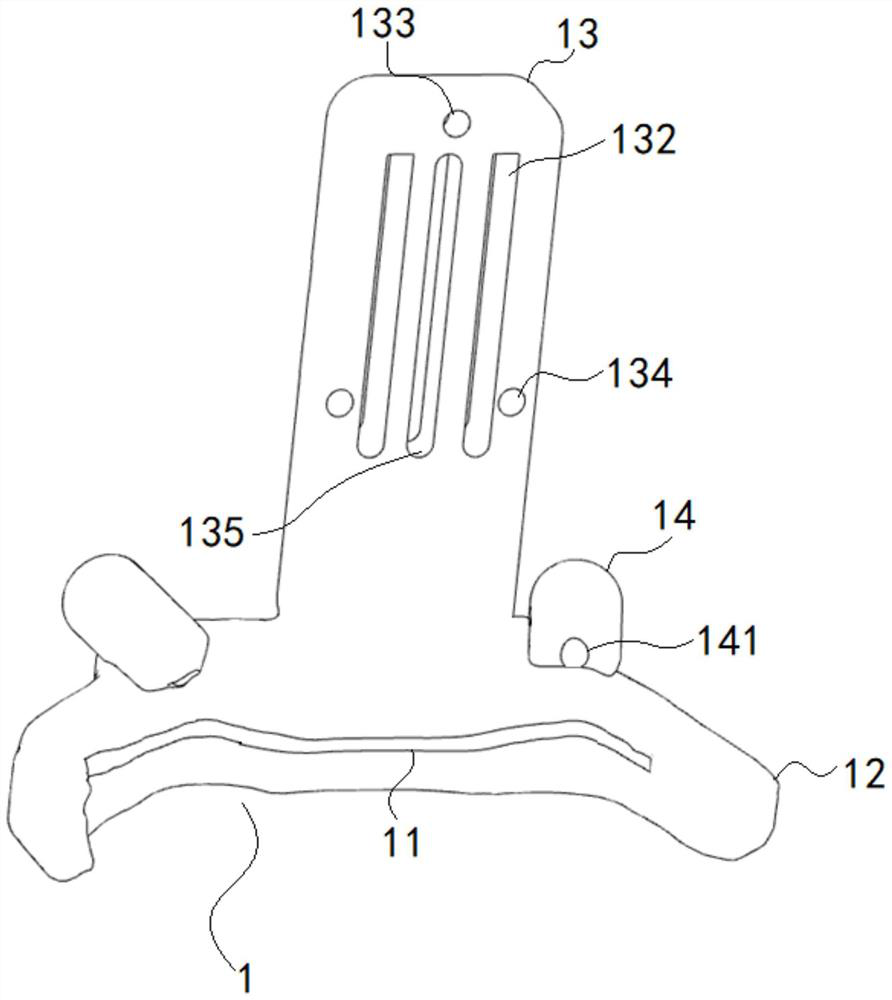

[0031] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings, and preferred embodiments described herein are intended to illustrate and explain the present invention, and is not intended to limit the invention.

[0032] In order to enable the hub, the prosthesis is implanted in accordance with the knee power line, and the prosthesis is increased, and the present invention provides a personalized adjustable junction guide, including the guide body 1 and the guide body 1. The positioning base 2 is provided on the guide bodies 1, and the tank tank 11 is provided for tanhing azand by the paste 11.

[0033] The guide body 1, the positioning base 2 can be printed by a nylon material, or a metal material;

[0034] During the specific application, the guide body 1 is used to oppose the first knife, and the positioning base 2 is used to determine the angle of the guide body 1 and positioned such that by the connected guide bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com