Fine drilling equipment for hardware production

A technology of drilling equipment and hardware, which is applied in the field of hardware, can solve the problems of increasing labor force, manual operation, etc., and achieve the effects of reducing labor force, preventing drilling failure, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

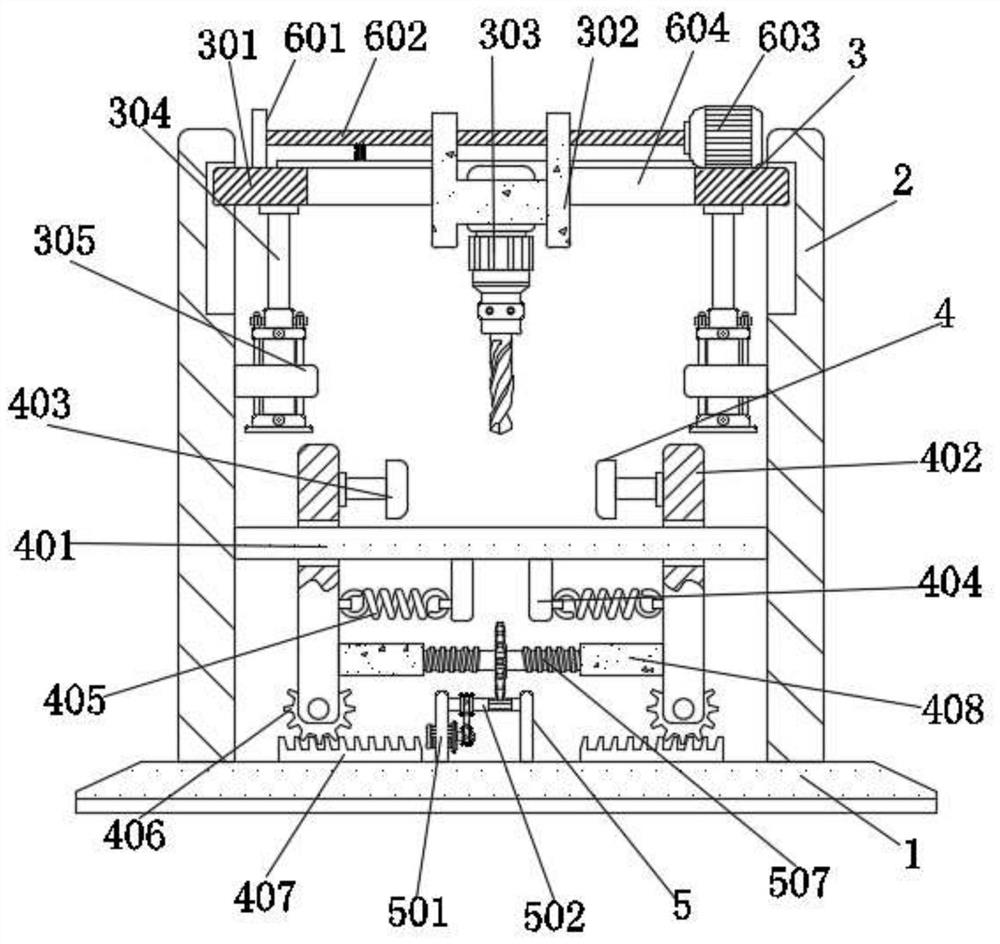

[0040] see figure 1 , 7 -10, the present invention provides a technical solution: a fine drilling equipment for hardware production, including a base 1 and a first vertical plate 2, the left and right sides of the upper surface of the base 1 are fixed with the first vertical plate 2, The upper inner side of the first vertical plate 2 is processed with a chute, the upper inner side of the first vertical plate 2 is equipped with a drilling device 3, and the drilling device 3 includes a first horizontal plate 301, an H-shaped plate 302, and the first horizontal plate 301 The outer wall of the outer side fits with the inner wall of the chute of the first vertical plate 2 in a gap, the first vertical plate 2 can limit the position of the first horizontal plate 301 through the chute, and the middle part of the first horizontal plate 301 is movably connected with an H-shaped plate 302 , the upper end of the first horizontal plate 301 is provided with a moving device, the moving devi...

Embodiment 2

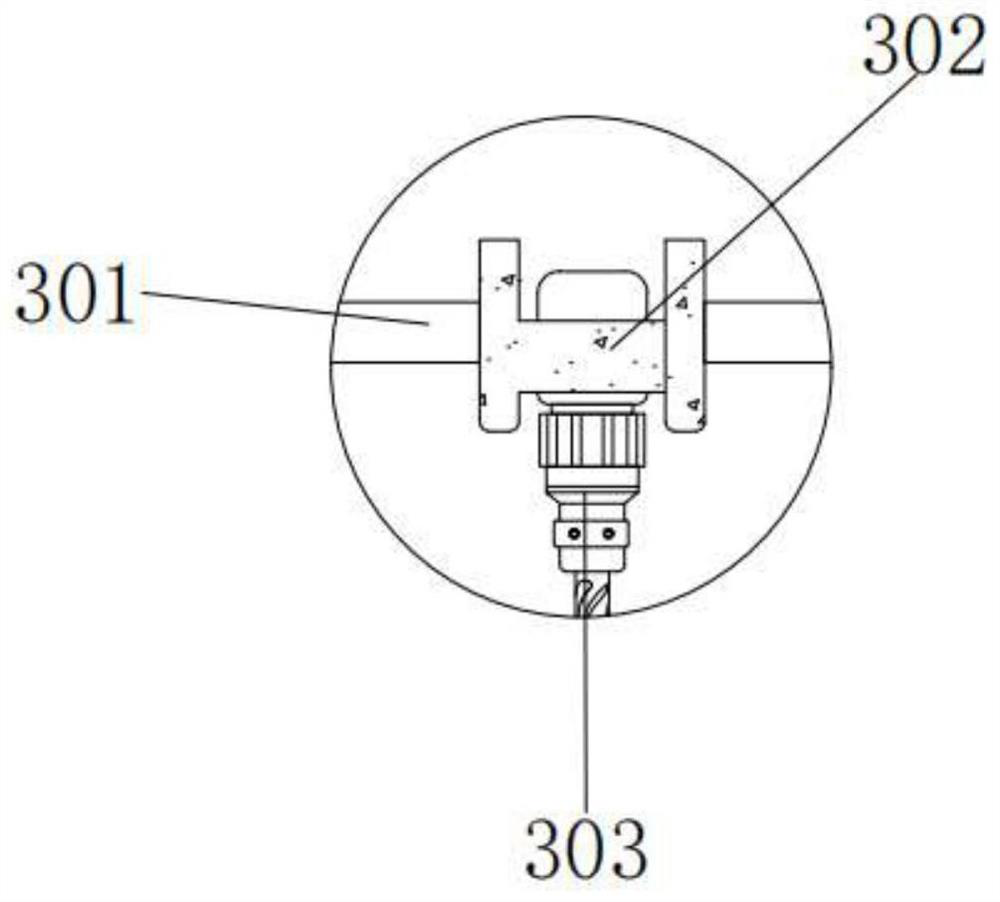

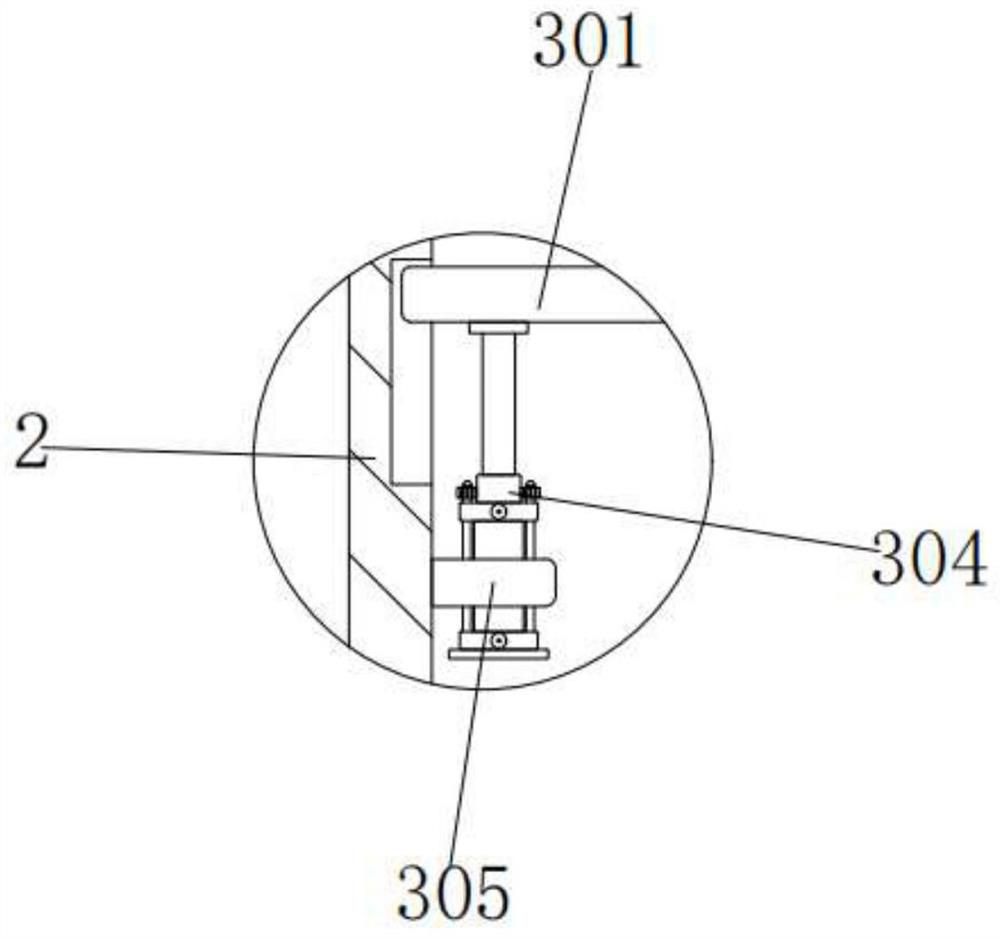

[0044] see Figure 1-6 As shown, on the basis of Embodiment 1, the drilling device 3 also includes a drilling machine 303, a hydraulic cylinder 304, and a second horizontal plate 305, and a drilling machine 303 is fixedly attached to the inside of the H-shaped plate 302. , the model of the drilling machine 303 is DW1-120D, the left and right sides of the drilling machine 303 are provided with a hydraulic cylinder 304, the model of the hydraulic cylinder 304 is MOB, the upper outer wall of the hydraulic cylinder 304 and the lower surface outer wall of the first horizontal plate 301 Fixedly connected, the hydraulic cylinder 304 can drive the drilling machine 303 to move through the first horizontal plate 301, etc., the second horizontal plate 305 is arranged below the first horizontal plate 301, and the inside of the second horizontal plate 305 is fixed to the outer wall of the hydraulic cylinder 304 connected, the outer outer walls of the left and right second horizontal plates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com