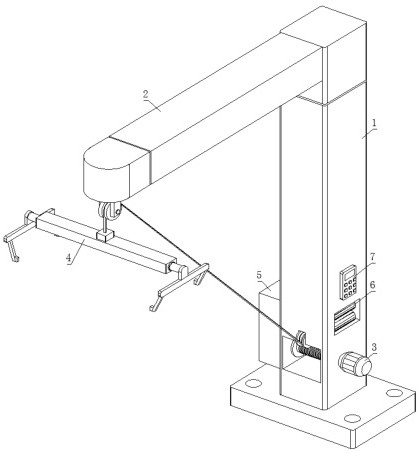

Grabbing device capable of automatically counting for shelving three-dimensional stored goods and implementation method

A technology of automatic counting and grabbing device, applied in storage device, hoisting device, conveyor control device, etc., can solve the problems of inconvenient use, low work efficiency, prone to counting errors, etc., and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0047] In order to further explain the above-mentioned embodiments better, the present invention also provides an embodiment, the implementation method of the automatic counting grabbing device used for placing the three-dimensional warehouse goods on the shelf, including the following steps:

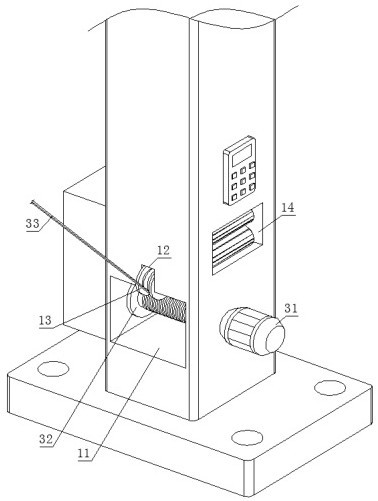

[0048] Step 1: When the operator needs to grab the goods, the control panel 7 can control and start the driving motor 31, so that the driving motor 31 simultaneously drives the H-shaped reel main body 321 and the threaded column 322 to rotate;

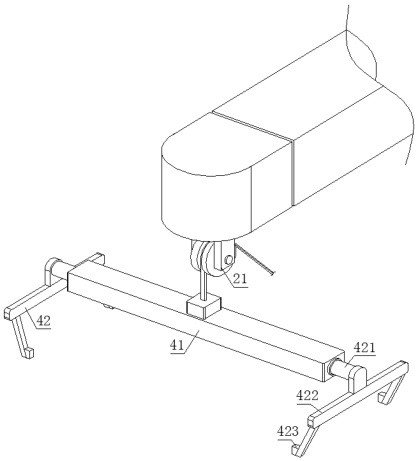

[0049] Step 2: The H-shaped reel main body 321 will pay off the connecting rope 33, so that the grab assembly 4 moves down along the second pulley 21. At this time, driven by the rotation of the threaded post 322, the one-way reel 323 will move to the right through the clamping action of the trapezoidal block 3243;

[0050] Step 3: When the lower end of the hydraulic grab arm 42 falls to the ground, the one-way runner 323 will squeeze the transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com