Arched bent suspension bridge structure

A bridge structure and bent frame technology, which is applied in bridges, suspension bridges, bridge construction, etc., can solve the problems of occupying a lot of land, and achieve the effect of beautiful structure, flexible layout and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

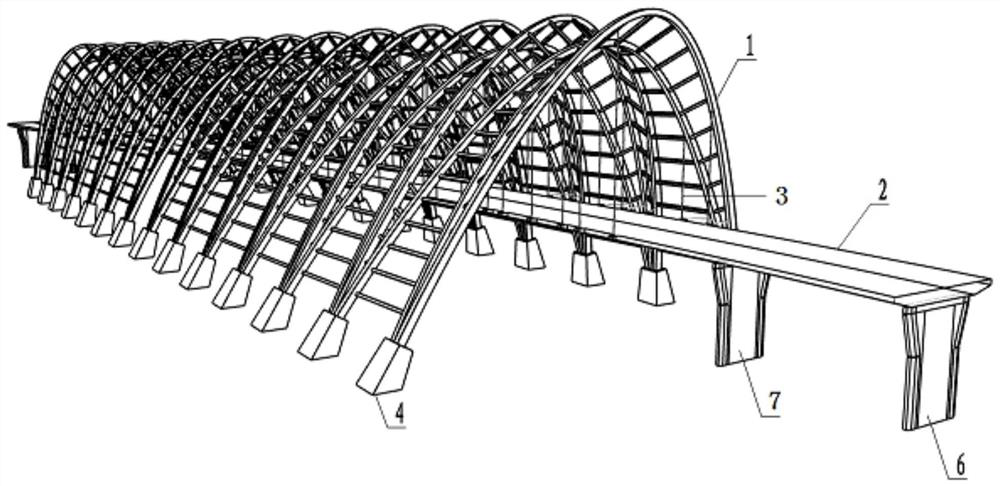

[0085] The present invention relates to an arch-bent suspension bridge structure, which comprises a longitudinal main girder 2 supported by side piers 6 below, or side piers 6 and auxiliary piers 7 . A plurality of sets of horizontal and parallel arch ribs 1 are arranged above the main beam 2 and span the main beam 2 , and vertical slings 3 are arranged between the arch ribs 1 and the main beam 2 .

[0086] The arch rib 1 includes three arc-shaped arches 11 , the middle arch 11 is vertical, the arches 11 on both sides are inclined outward, and multiple ribs 12 are arranged between adjacent arches 11 . like figure 2 Arch rib 1 located in the middle.

[0087] The arch rib 1 may also include two arc-shaped arches 11, the two arches 11 are vertical or outwardly inclined, and multiple ribs 12 are arranged between them. like Figure 4 Arch ribs in 1.

[0088] The arch rib 1 may also include two arc-shaped arch frames 11, one arch frame 11 is vertical, the other arch frame 11 is...

Embodiment 2

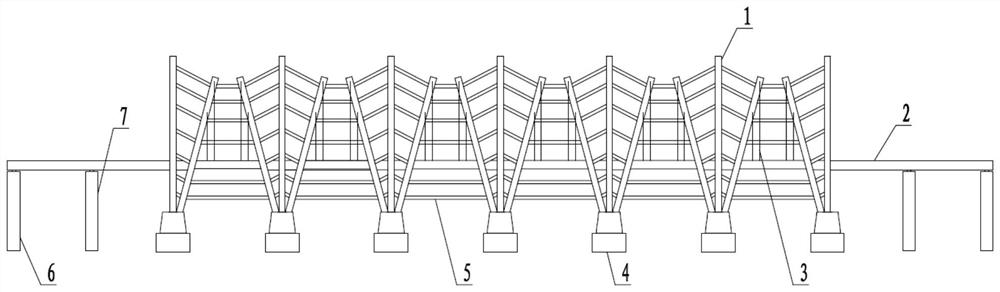

[0102] In this embodiment, the arch ribs 1 in Embodiment 1 are changed to two arches 11 in each group, and the two arches 11 are respectively inclined to both sides and connected by vertical braces 5 . The rest of the structure is the same as in Example 1.

Embodiment 3

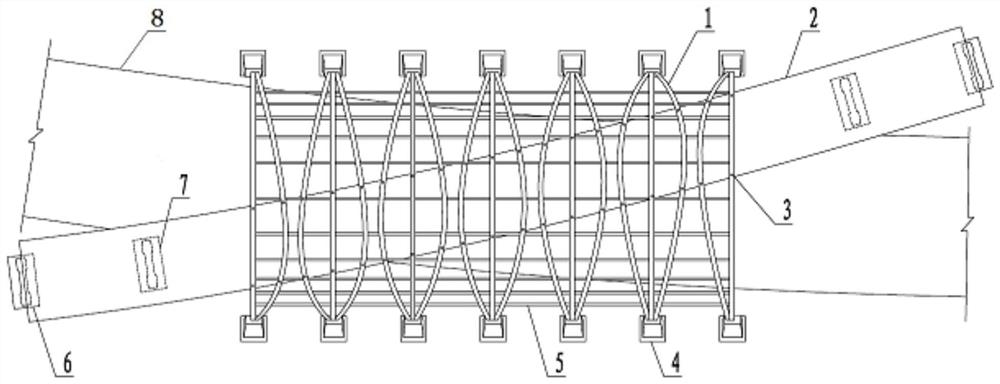

[0104] Figure 4 It is the plan view of the main structure of Example 3, and the system consists of arch ribs 1, main beams 2, slings 3, abutment foundations 4, longitudinal braces 5, and side piers 6.

[0105] The arch rib 1 adopts a circular steel pipe cross-section, and the two arch frames 11 are arranged in parallel, and are connected by a number of vertical braces 5, which adopt a circular steel pipe cross-section. The two arches 11 share a set of abutment foundations 4, the abutment foundations 4 are respectively located on both sides of the sideline of the road 8 on the ground floor, and the arch rib 1 crosses the road 8 on the ground floor horizontally. Several groups of above-mentioned arches are arranged along the route direction of the road 8 on the ground floor, some of which are arranged parallel to each other, and some of which are arranged at a certain angle with the front group of arches to adapt to the plane alignment of the main beam 2. Each group of arches ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com