Stable-rotation net rack support

A technology for stable rotation and positioning of supports, which is applied to buildings and building structures, etc., can solve the problems of increasing the workload of large-span grid structures, the investment of personnel and equipment, and the workload of other equipment, so as to reduce the workload and reduce costs. The investment of personnel and equipment, the safe and reliable effect of the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

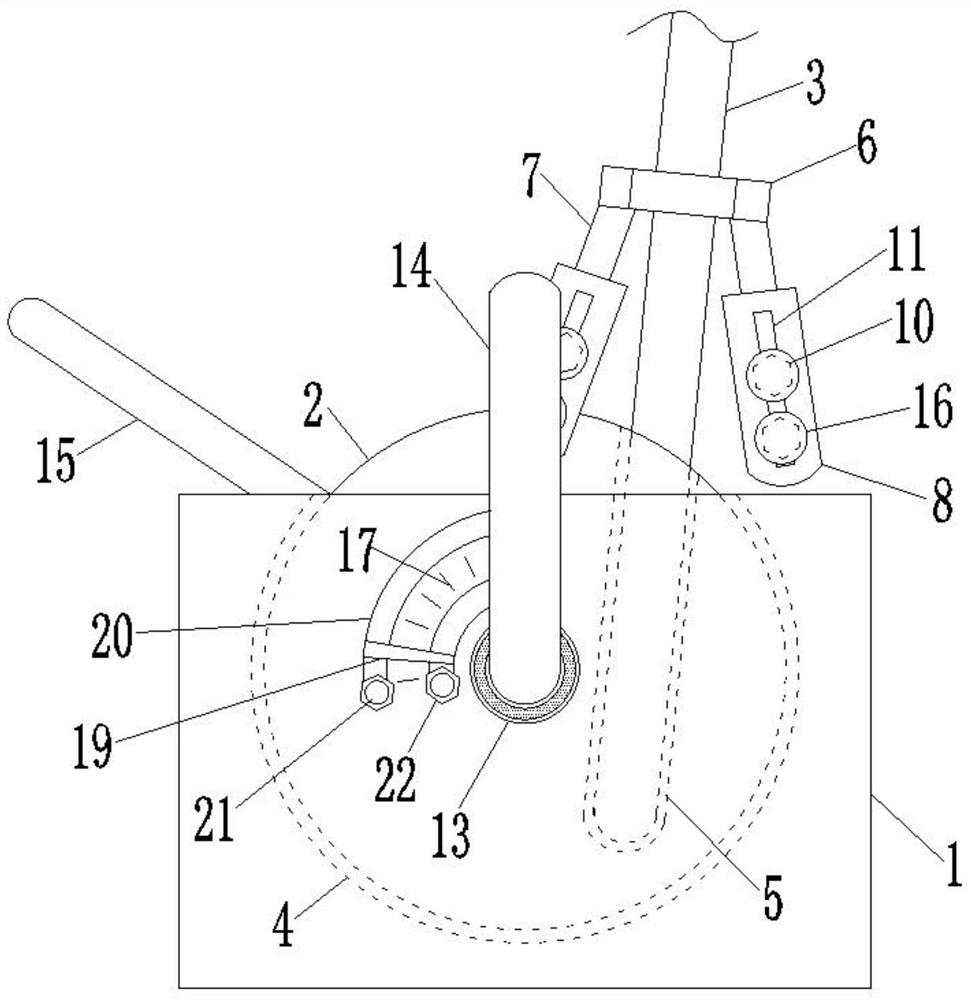

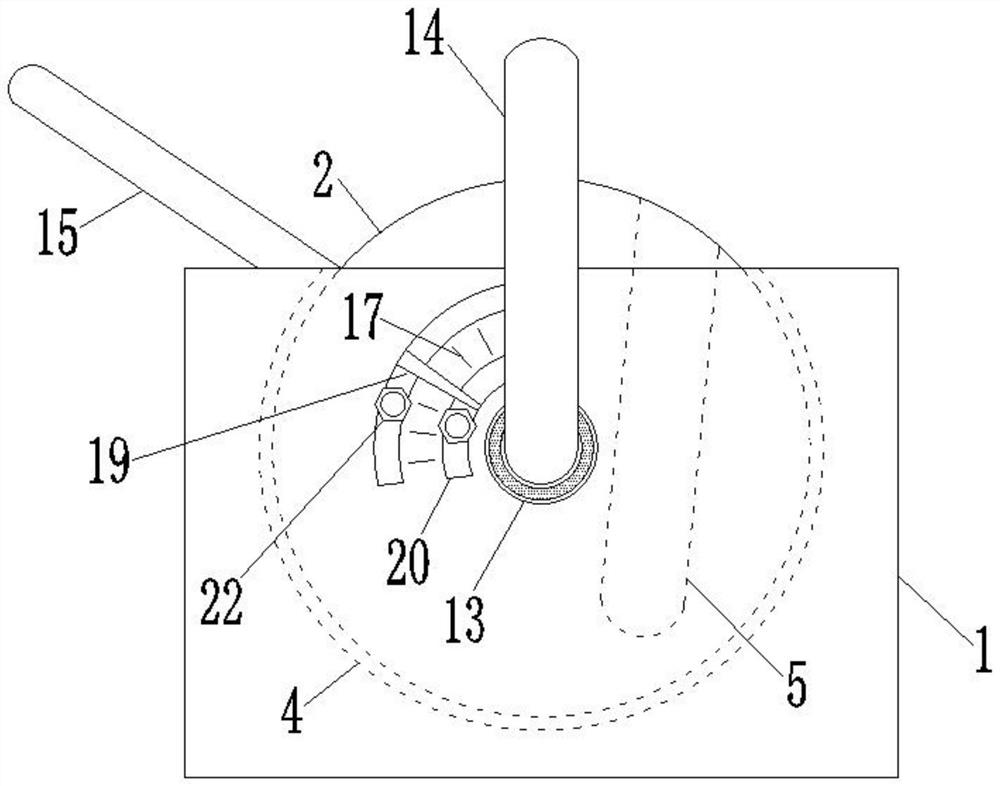

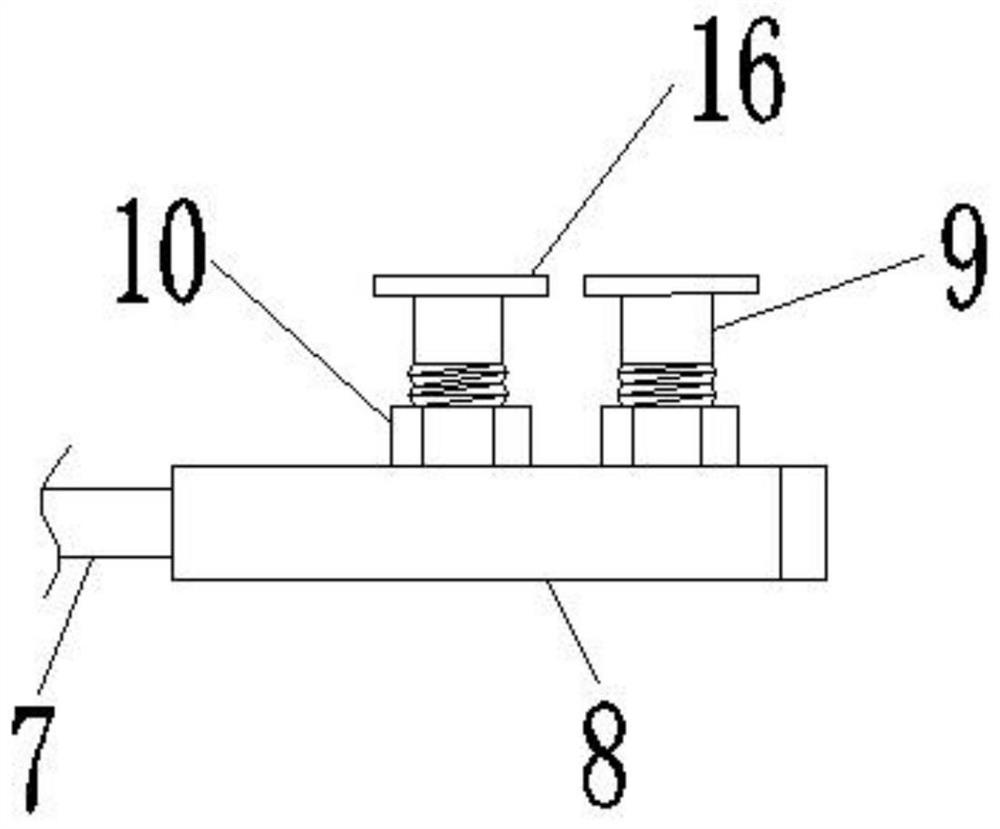

[0037]In the present invention, the positioning support 1 is fixedly installed on the left side of the installation position of the large-span network frame, and the connection cavity 5 is provided on the ball joint 2 according to the installation angle and state of the movable end 3 of the network frame on the left side of the large-span network frame. The movable end 3 of the network frame is fixed in the connection cavity 5 by means of the above-mentioned method. At this time, the movable end 3 of the network frame on the right side of the large-span network frame is relatively free. The joint 2 rotates as a fulcrum so that the movable end 3 of the grid on the right is far away from the installation position and the installation support on the right; before the rotation, first calculate the rotation angle of the ball joint 2 according to the size of the grid structure and the degree of rotation, and then Move the position of the outer limit block 19 according to the angle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com