Manned device suitable for coal mine thin seam fully mechanized coal mining face

A technology for fully mechanized mining face and thin coal seam, applied in the field of coal mines, can solve the problems of inconvenient walking, no good, and inability to move maintenance personnel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

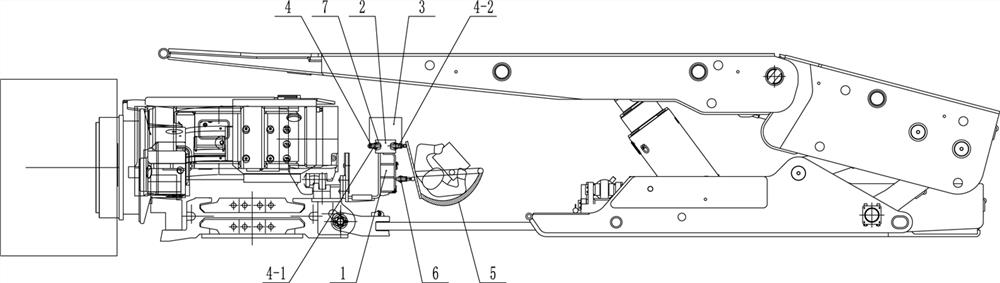

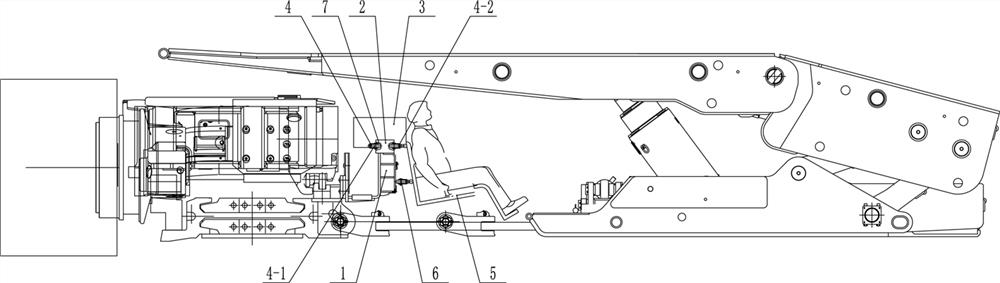

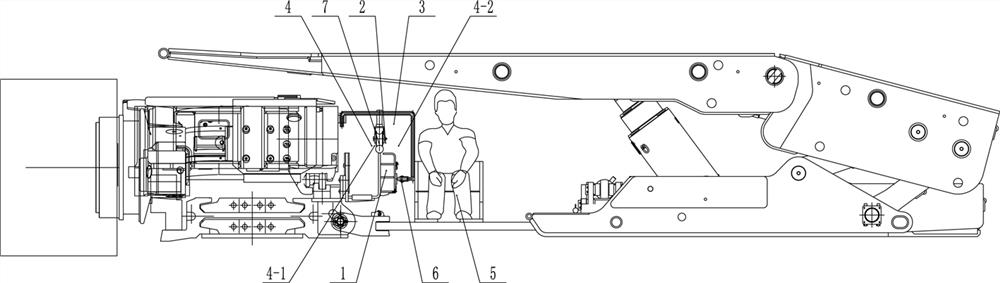

[0026] Such as Figure 1-Figure 4 As shown, a manned device suitable for fully mechanized coal mining face in thin coal seam includes guide rail 2 laid along cable rack 1 of conveyor, driving device 3, driving pulley 4, manned cabin body 5 and adjustable pulley 6.

[0027] The rail surface of described guide rail 2 is left and right sides, and the rail surface of described guide rail is set as groove type rail surface 7, and described driving pulley comprises left pulley 4-1 and right pulley 4-2, and left pulley and right pulley can be A group of pulleys is used to prevent a single pulley from being unable to carry the weight of the sitting position. The left pulley 4-1 and the right pulley 4-2 are clamped on the grooved rail surface 7 of the guide rail in a rolling and clamping manner. Driving device 3 drives left pulley 4-1 and right p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com