Electromagnetic defrosting air cooler

A cooling fan and electromagnetic technology, applied in coolers, refrigerators, defrosting, etc., can solve the problems of long defrosting time, unevenness, and low efficiency, and achieve high-efficiency heating effects, uniform frosting speed, and high thermal efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

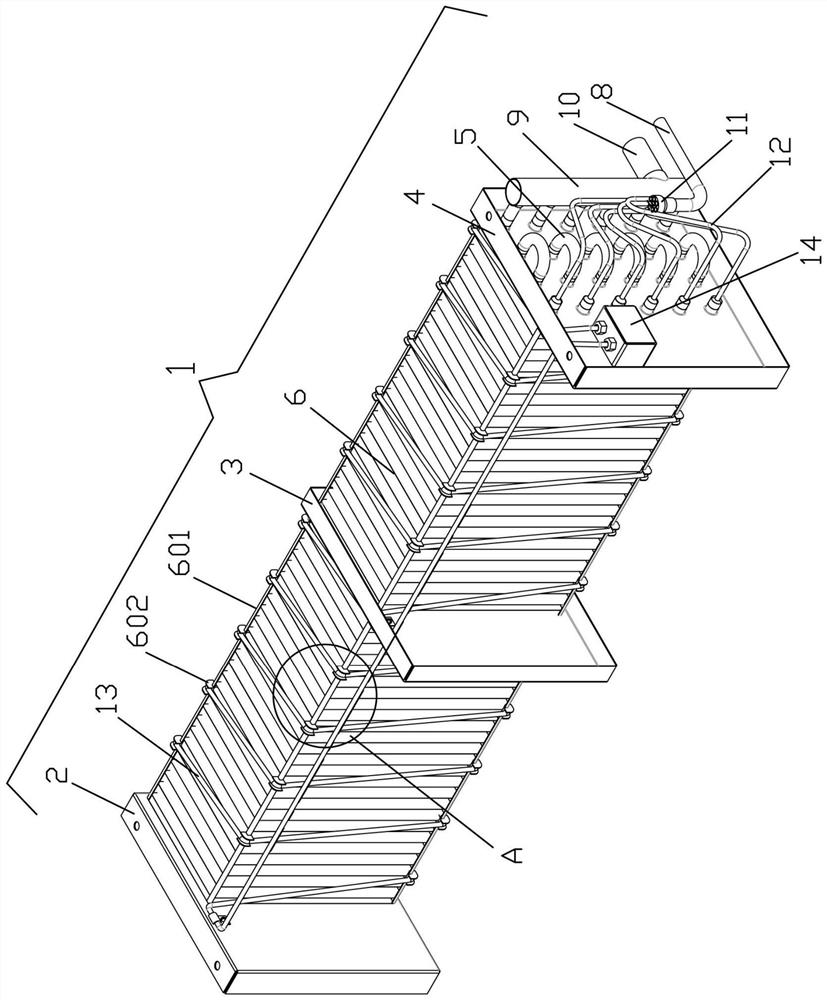

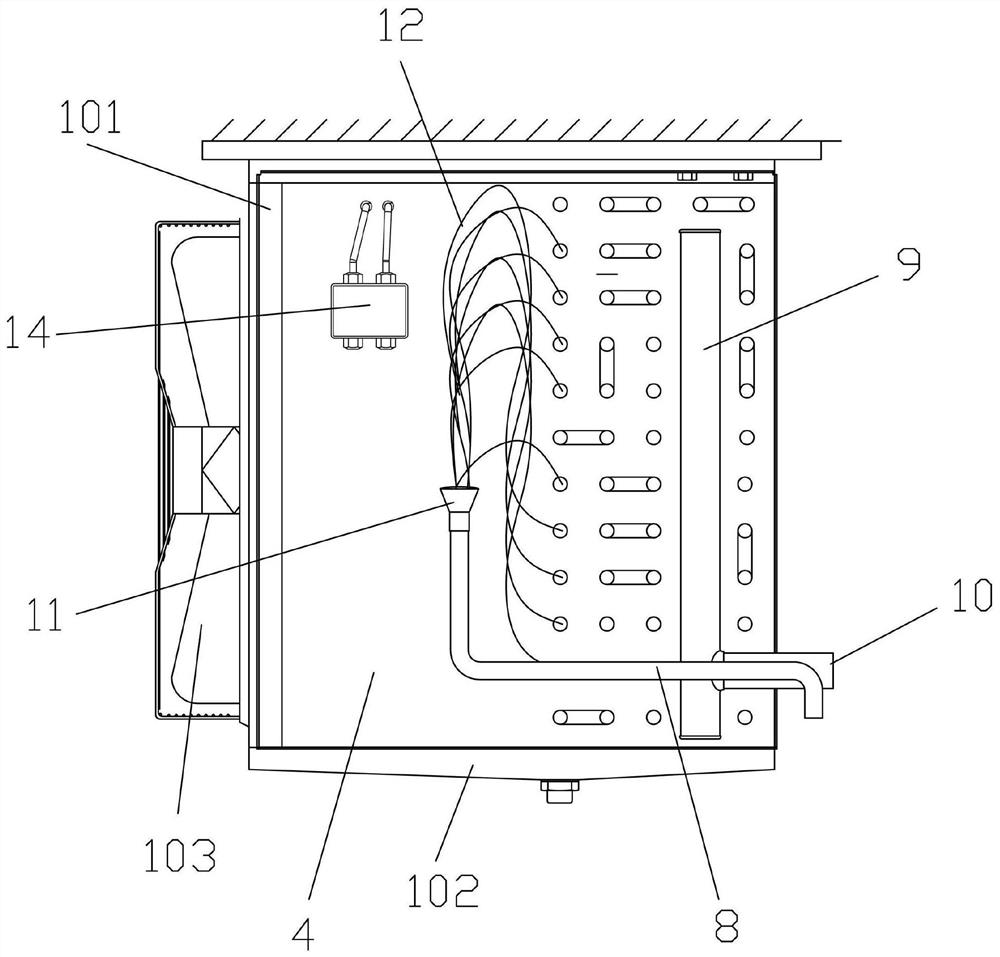

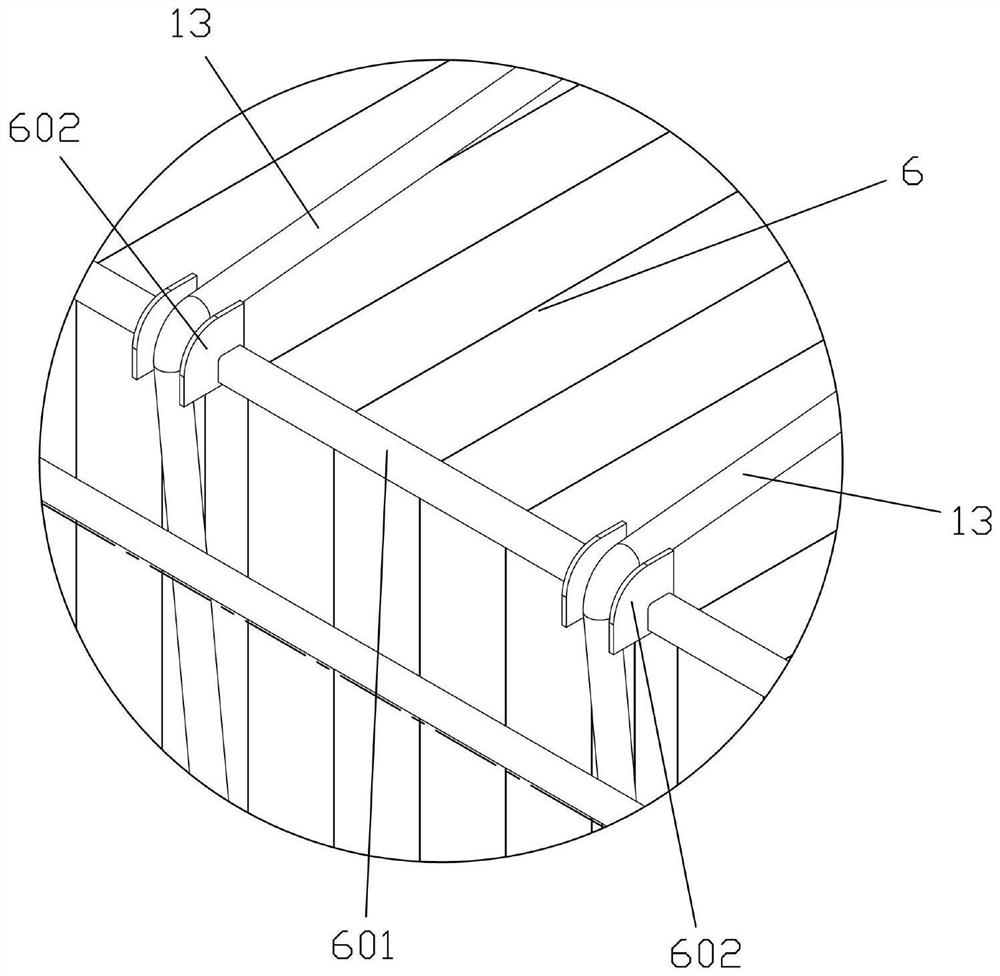

[0017] Embodiment: a kind of electromagnetic frost air cooler, such as Figure 1-Figure 4 As shown, the air cooler body 1 is included, and the air cooler body 1 includes a through plate 2, an intermediate plate 3, a mounting plate 4, an air cooler heat exchange tube 5 and an air cooler housing 101, and the through plate 2 is arranged on the intermediate plate 3 On the left side of the middle plate 3, the mounting plate 4 is arranged on the right side of the middle plate 3, and between the through plate 2 and the middle plate 3 and between the loading plate 4 and the middle plate 3 are provided with cooling fan heat exchange fin groups 6, The heat exchange fin group 6 of the air cooler is composed of several heat exchange fins arranged equidistantly, and several heat exchange tubes 5 of the air cooler are interspersed in the heat exchange fin group 6 of the air cooler. The machine heat exchange tubes 5 are evenly distributed in serpentine disks and are arranged in the heat exch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com