A cooling device for fracturing vehicles

A technology of cooling device and fracturing truck, which is applied to water shower coolers, wellbore/well components, lighting and heating equipment, etc., can solve the problem of increasing the flow resistance of cooling pipes, increasing the power loss of cooling fluid, and adversely saving water resources. and other problems to achieve the effect of improving cooling efficiency, improving uniformity and reducing water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

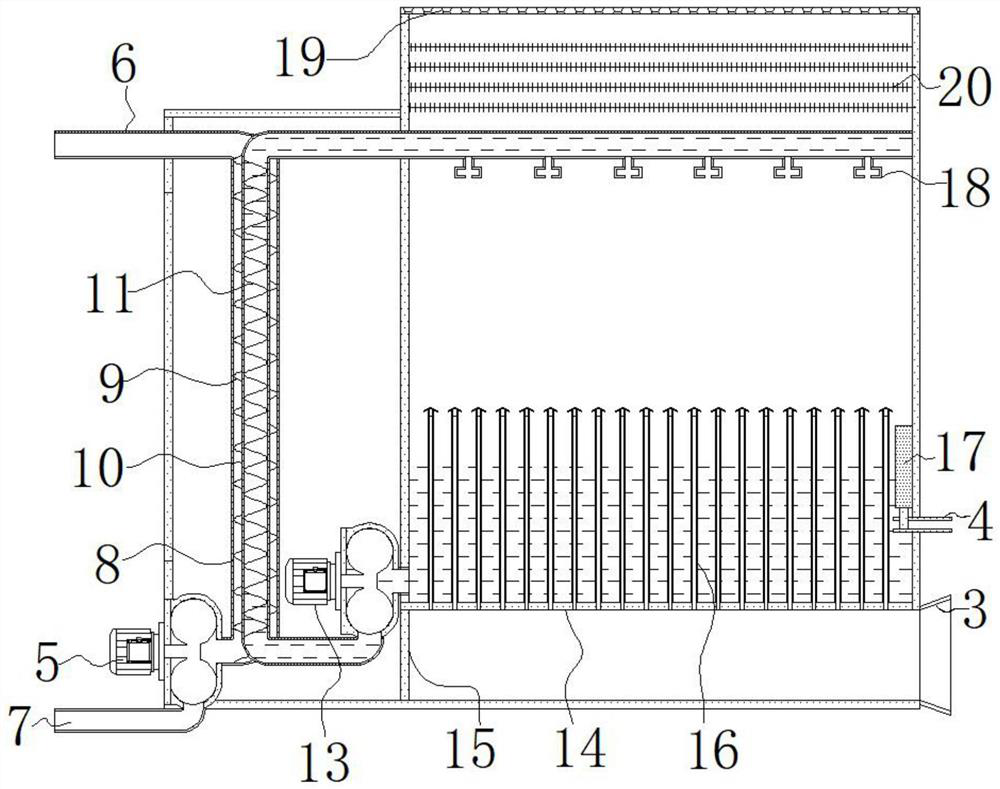

[0027] As a preferred embodiment of the present invention, one end of the inner pipe 10 is welded to one side of the water tank 14 , and one end of the inner pipe 10 is connected to the spray heads 18 , and the spray heads 18 are evenly distributed on the inner pipe 10 .

[0028] As a preferred embodiment of the present invention, the other end of the inner pipe 10 passes through the other side of the water tank 14, the top of the casing 8, the screw plate one 9 and the bottom of the casing 8 in sequence and connects with the water pump two 13 The bottom is connected, and one side of the water pump two 13 is connected with the other side of the water tank 14. The water pump two 13 passes the cold water in the water tank 14 into the inner pipe 10, and in the inner pipe 10, guided by the screw plate two 11 Rotate downwards and flow upwards, so that the heat-absorbing moisture flows upwards along the middle of the inner tube 10, and the moisture with low temperature flows upwards ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com