A negative pressure steam breakthrough curve analysis device and using method thereof

A breakthrough curve and analysis device technology, which is applied in the field of negative pressure steam penetration curve analysis device, can solve the problems of uneven steam, unsatisfactory test, influence, etc., and achieve the goal of reducing poisoning, stabilizing and uniform steam flow, and avoiding influence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

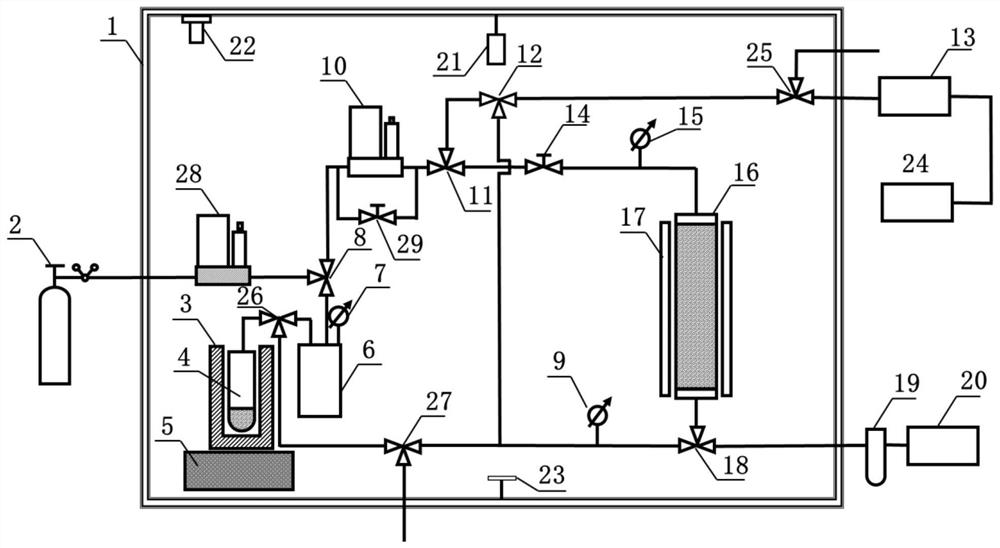

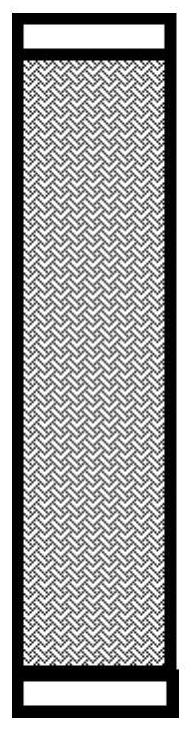

[0092] figure 1 As shown, this embodiment provides a negative pressure steam breakthrough curve analysis device, including a housing 1, and the housing 1 is provided with a purging unit, a breakthrough adsorption unit, a vacuum activation unit and an organic steam generating unit. The organic steam generation unit, the purging unit and the penetration adsorption unit are respectively connected to the first three-way valve 8 independently. By switching the first three-way valve 8, the organic steam generation unit and the penetration adsorption unit are connected, or the organic steam generation unit Connected with the purging unit; the penetration adsorption unit, the vacuum activation unit and the organic vapor generation unit are respectively connected to the second three-way valve 18 independently, and the communication between the vacuum activation unit and the penetration adsorption unit is realized by switching the second three-way valve 18, Or the vacuum activation unit...

Embodiment 2

[0106] This embodiment provides a negative pressure steam breakthrough curve analysis device, which is different from Embodiment 1 in that the first pressure measuring component 15 and the second pressure measuring component 9 in the breakthrough adsorption unit are both pressure sensors , the pressure sensor can be used in conjunction with the second mass flow controller 10 and the power pump 13, and the penetrating column 16 is 95mm in height and 5mm in diameter.

Embodiment 3

[0108] This embodiment provides a negative pressure steam breakthrough curve analysis device, which is different from Embodiment 1 in that two organic steam generating units are arranged in the casing 1 and are respectively connected to the steam buffer 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com