Control method of heating furnace hot-delivery transverse-moving steel pushers based on dynamic correction

A technology of dynamic correction and control method, applied in the direction of adaptive control, general control system, control/adjustment system, etc., can solve problems such as billet stuck, high failure rate, billet tilt, etc., to improve the degree of automation and work. Efficiency, shorten the production cycle, improve the effect of heat transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to deepen the understanding of the present invention, the present invention will be further detailed in connection with the present invention, and the present embodiment is intended to be construed as limiting the scope of the invention.

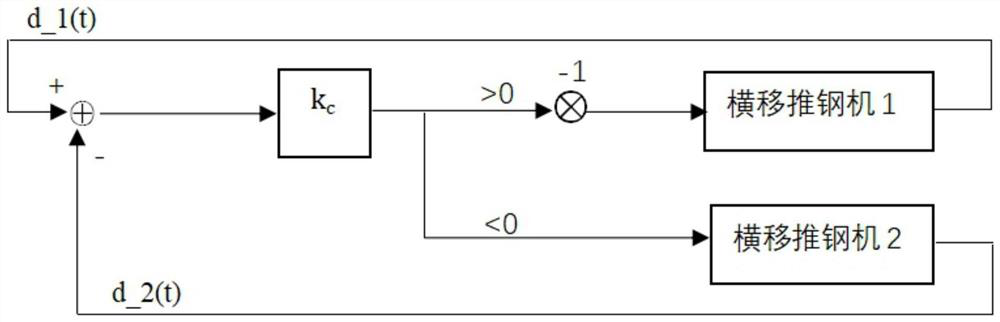

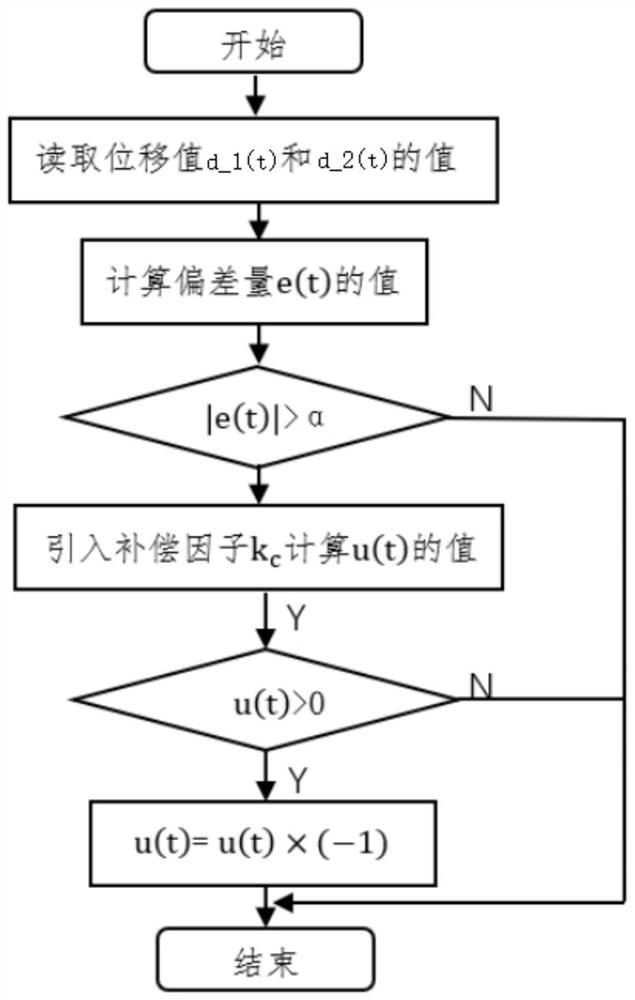

[0030] according to figure 1 , 2 As shown, the present embodiment proposes a control method of a thermal transmission transverse steel machine based on a dynamic correction, including the following steps:

[0031] Step 1: The displacement detector and the AD conversion module are used to detect the motion stroke of two transverse push steel machines, respectively;

[0032] Step 2: Set a start position approach switch, access the offset displacement value D0_1 and D0_2 when two transverse switches when the switch and the displacement detector are obtained by the start position.

[0033] Step 3: Set an intermediate position proximity switch, approach the switch and the displacement detector through the intermediate position to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com