A performance optimization method of marine gas turbine compressor based on three-dimensional flow field analysis

A technology of three-dimensional flow field and optimization method, applied in design optimization/simulation, instrumentation, geometric CAD, etc., can solve problems such as low efficiency and pressure ratio, achieve the effect of eliminating air separation, reducing time consumption, and improving thermal insulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in more detail below in conjunction with the accompanying drawings:

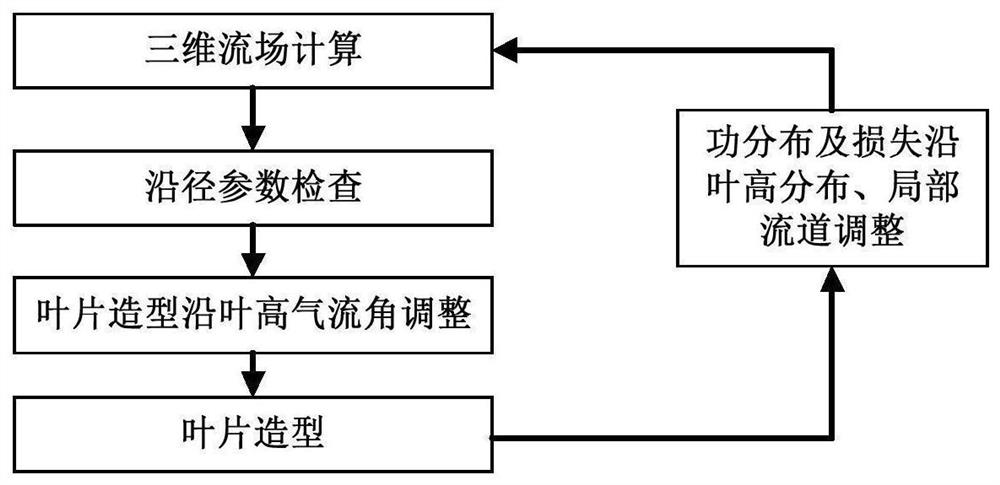

[0024] combine figure 1 , a specific implementation of a performance optimization design method for a high-performance marine gas turbine compressor based on three-dimensional flow field analysis is achieved through the following steps:

[0025] Step 1: Under the condition of the compressor at the design point, select the characteristic section of the optimization calculation; usually, different relative height positions along the blade height are used as the characteristic section, generally 5 or 7 sections are selected, and the spacing between the sections is kept equal.

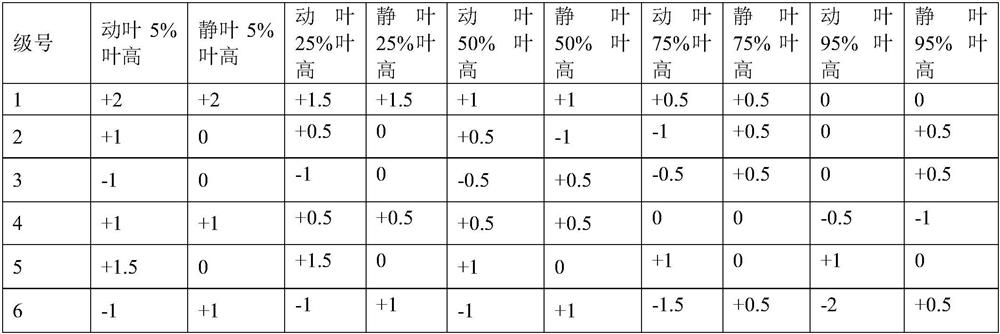

[0026] Step 2: Extract the main aerodynamic parameters at the characteristic cross-section positions of the blades at the inlet of the compressor at the design point, including: the relative velocity W at the inlet of the rotor blade 1 , the relative velocity of the rotor blade outlet W 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com