Supercritical carbon dioxide silicon block cleaning device and silicon block processing system and method

A carbon dioxide and treatment method technology, applied in chemical instruments and methods, cleaning methods and utensils, electrical components, etc., can solve problems such as failure of crystal pulling, excessive impurities on the surface of silicon blocks, and difficult process control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

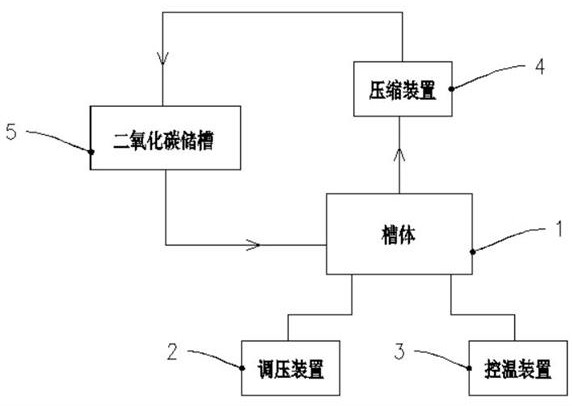

[0054] Such as figure 1 As shown, a supercritical carbon dioxide silicon block cleaning device includes: a tank body 1, providing a closed space for cleaning silicon blocks, and at least for liquid carbon dioxide and silicon blocks to enter, and for gaseous carbon dioxide and silicon blocks leave; the pressure regulating device 2 adjusts the pressure in the enclosed space to a supercritical pressure higher than carbon dioxide before the silicon block is cleaned, and keeps the pressure constant during the cleaning process; and lowers the pressure in the tank body 1 after the silicon block is cleaned. Pressure, so that carbon dioxide gasification; temperature control device 3, the temperature in the closed space is adjusted to be higher than the supercritical temperature of carbon dioxide before the silicon block is cleaned, and the temperature is kept constant during the cleaning process; The gasified carbon dioxide in the body 1 is compressed to form liquid carbon dioxide; the...

Embodiment 2

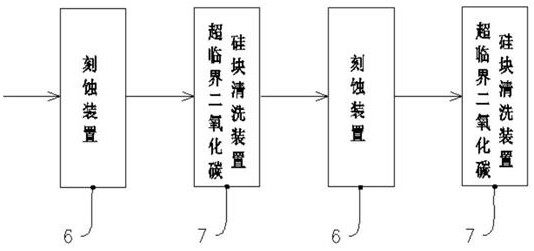

[0058] As shown in Fig. 2, a kind of silicon block processing system comprises: two-stage processing unit, each stage processing unit comprises: etching device 6, to the partial impurity etching removal of silicon block; supercritical carbon dioxide silicon block cleaning device 7, The etched silicon block is cleaned.

[0059] Wherein, supercritical carbon dioxide silicon block cleaning device 7 comprises: tank body 1, provides the enclosed space for carrying out silicon block cleaning, and at least for liquid carbon dioxide and silicon block to enter, and, for gaseous carbon dioxide and silicon block to leave; pressure device 2, before the silicon block is cleaned, the pressure in the closed space is adjusted to a supercritical pressure higher than carbon dioxide, and the pressure is kept constant during the cleaning process; and, after the silicon block is cleaned, the pressure in the tank body 1 is reduced, and Make the carbon dioxide vaporize; the temperature control devic...

Embodiment 3

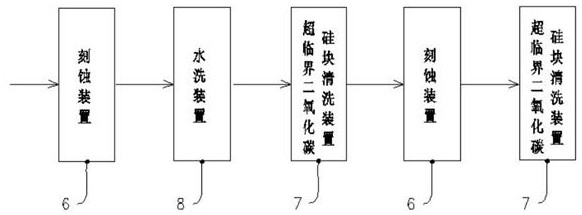

[0062] The difference between this embodiment and the second embodiment is that in order to improve the removal effect of the first-level processing unit on impurities, such as image 3 As shown, the first-level processing unit also includes a water washing device 8, which washes the silicon block from the etching device 6, and the silicon block after water washing is cleaned by supercritical carbon dioxide, so that the removal effect of impurities is further improved. promote.

[0063] In this embodiment, the silicon block does not need to be additionally dried, and the CO 2 Most of the water and acid in the micropores can be washed out, avoiding the residue in the micropores.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap