Composite leg-foot mechanism and 3-ups parallel wheel-foot composite bouncing robot

A 3-UPS, robot technology, applied in the field of robots, can solve the problems of lack of composite robots and slow development, and achieve the effect of improving flexibility and increasing bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

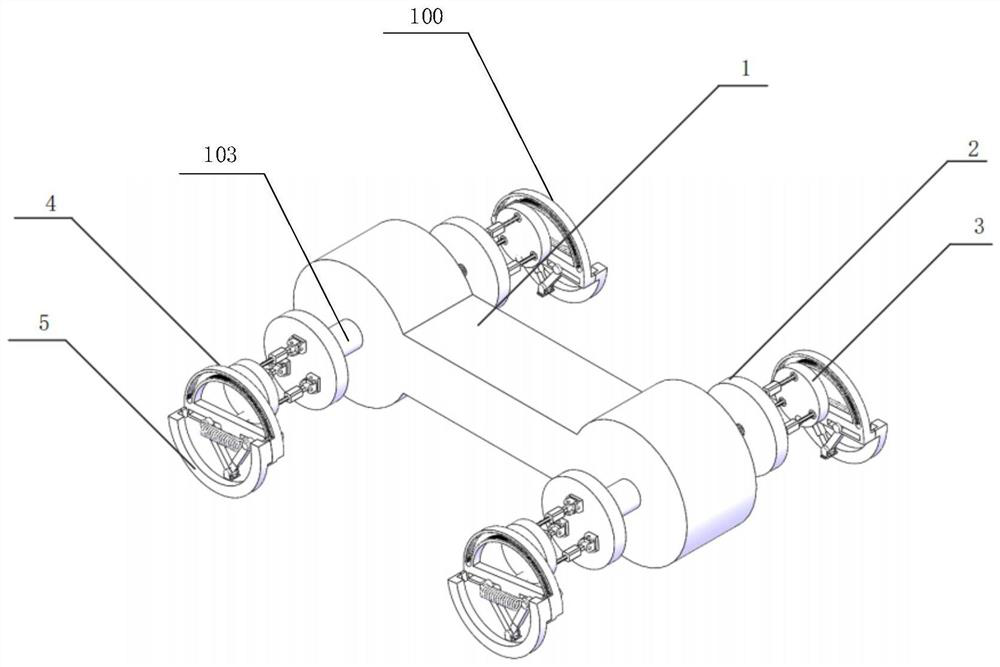

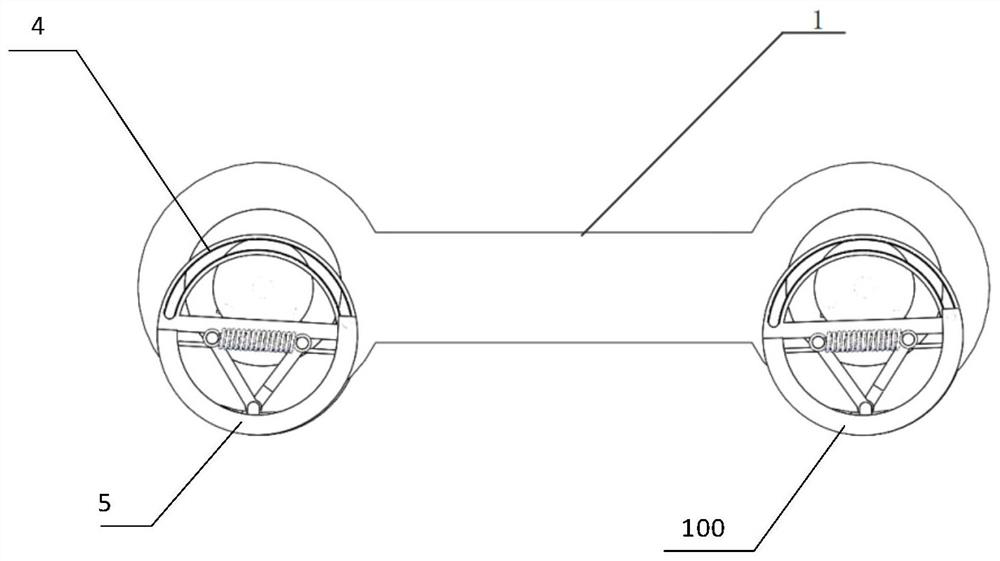

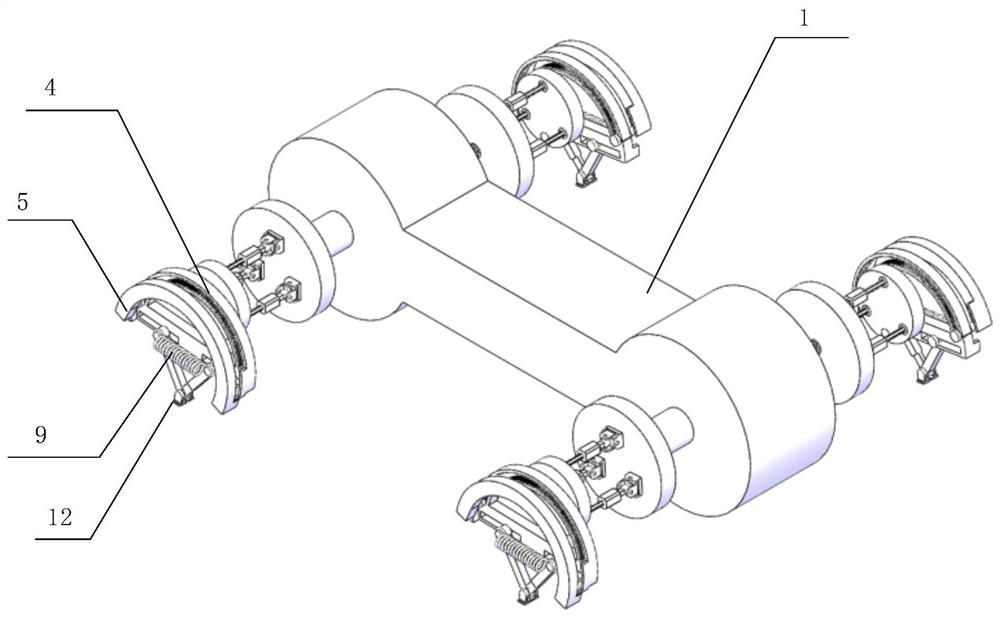

[0029] Such as Figure 1 to Figure 9 Shown:

[0030] The 3-UPS parallel wheel-foot composite bouncing robot of the present invention includes a fuselage 1 and composite leg-foot mechanisms arranged symmetrically on both sides of the fuselage 1 . In this embodiment, the fuselage 1 is in the shape of a dumbbell, and there are 4 sets of composite leg-foot mechanisms, which are placed on both sides of the fuselage 1 in pairs. The structure of one group of compound leg-foot mechanisms is taken as an example below, and the other three groups are the same, and will not be described in detail.

[0031] The composite leg-foot mechanism includes an upper semi-circular ring 4, a lower semi-circular ring 5, a static platform 2, a parallel swing mechanism, and a dynamic platform 3. A threaded rod 103 is fixedly threaded at both ends of the long axis of the fuselage 1, and the two ends of the threaded rod 103 protrude from the fuselage 1 and are fixedly connected to a static platform 2, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com