Damping device

A technology of damping device and elastic reset device, which is applied in the field of damping device, can solve the problems of low degree of automatic production, high production cost and low production efficiency, and achieve the effects of reducing labor intensity, low production cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

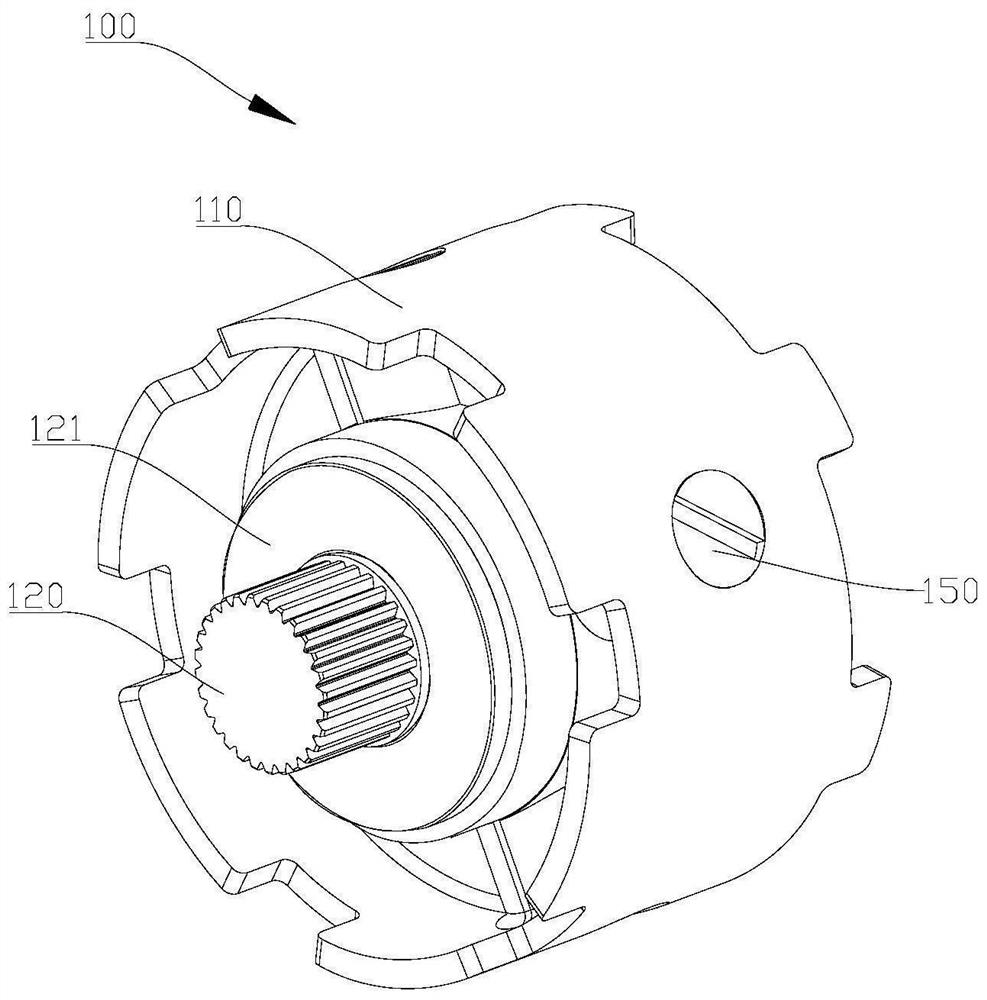

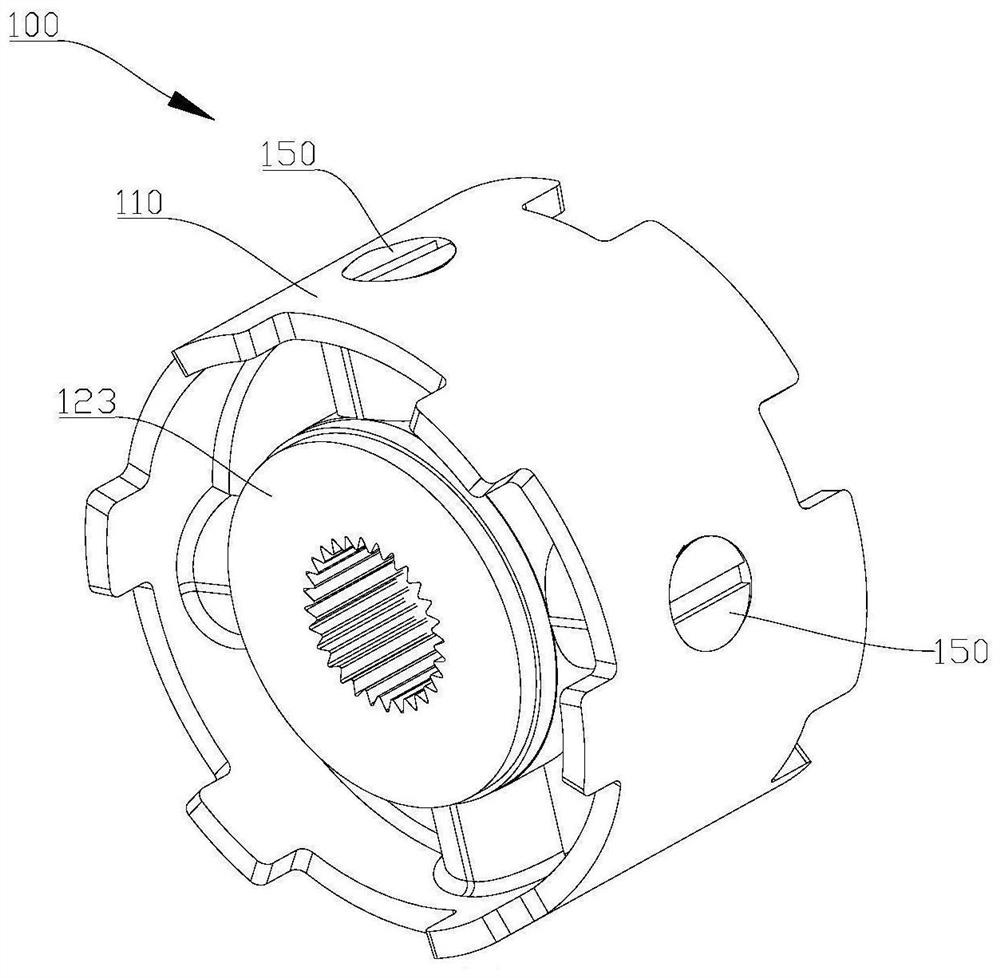

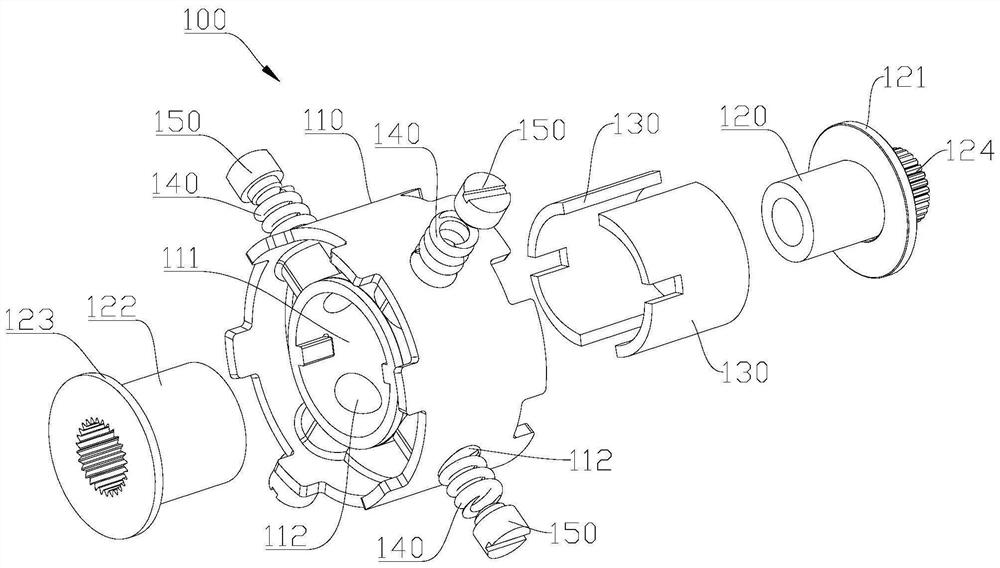

[0039] like Figure 1 to Figure 3 As shown, the structure of the damping device 100 includes a cage 110 , a mandrel 120 , a friction bush 130 , a compression spring 140 and a screw 150 . The cage 110 is used to support the mandrel 120 , the friction bearing shell 130 , the compression spring 140 and the screw 150 .

[0040] The cage 110 is cylindrical and is provided with a first accommodating hole 111 and a second accommodating hole 112 . The first accommodating hole 111 penetrates through the cage 110 in the axial direction. The second accommodating hole 112 is radially extended on the holder 110 and has an opening on the side wall 113 of the holder 110 . The first receiving hole 111 communicates with the second receiving hole 112 . There are a plurality of second accommodation holes 112 uniformly distributed along the circumferential direction, and the specific number can be determined according to the number of compression springs 140 to be provided.

[0041] like im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com