Independent temperature and humidity control system for plant cabin in severe cold area

An independent control, temperature and humidity technology, applied in the direction of botanical equipment and methods, applications, refrigerators, etc., to achieve the effect of improving evaporation heat transfer efficiency, reducing floor space and installation space, and large heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

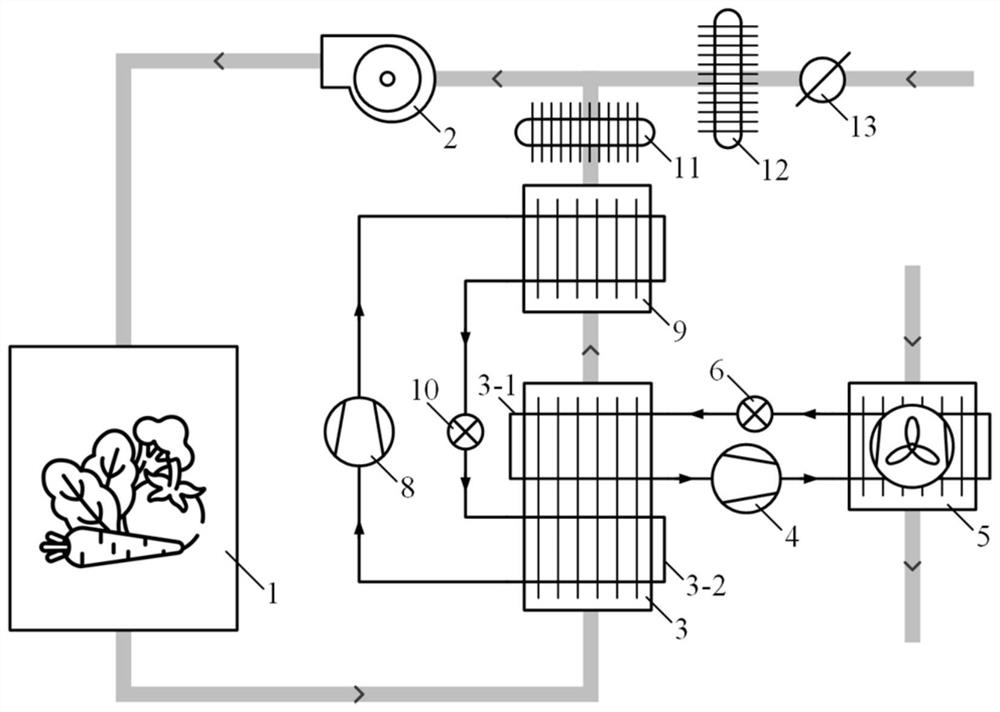

[0045] The present invention is used for the temperature and humidity independent control system of the plant cabin in severe cold area (referring to figure 1 ), including the first refrigerant circulation flow path (refrigeration system) for temperature regulation, the second refrigerant circulation flow path (dehumidification system) for humidity regulation, the air circulation flow path in the plant cabin, the outdoor fresh air flow path, and the outdoor air cooling flow road.

[0046] The first refrigerant circulation flow path for temperature regulation, including the refrigeration system refrigerant evaporation heat exchange pipeline 3-1 of the joint evaporator 3, the refrigeration system compressor 4, the refrigerant channel of the refrigeration system condenser 5 and the refrigeration system connected in sequence The system throttling element 6, the refrigeration system throttling element 6 is connected with the refrigeration system refrigerant evaporation heat exchang...

Embodiment 2

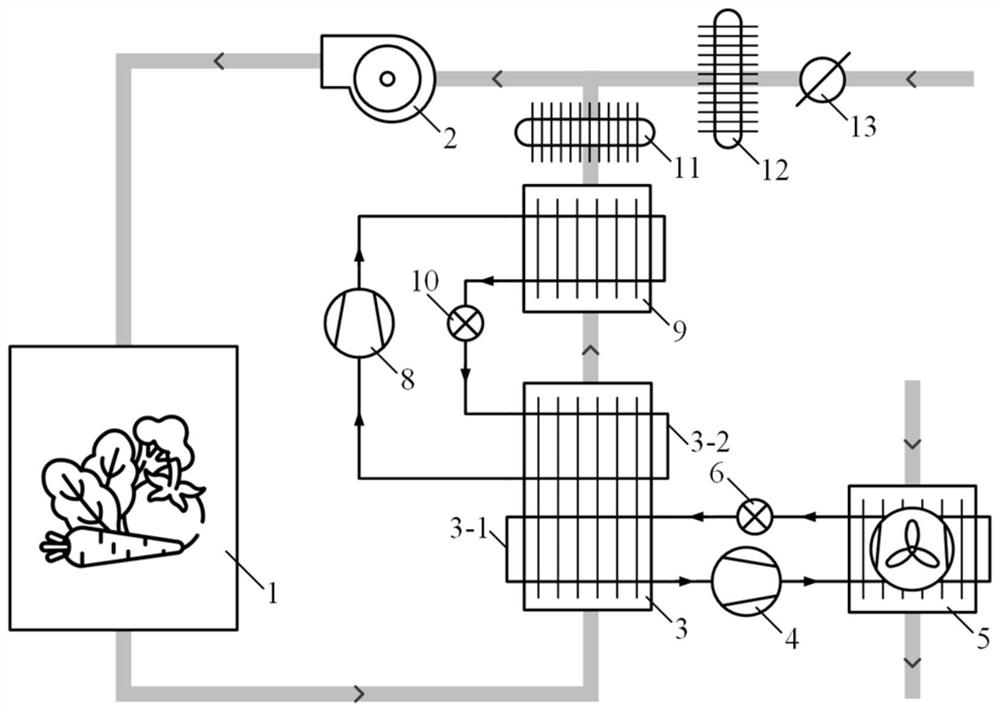

[0065] The basic principle of this embodiment is similar to Embodiment 1 (see figure 2 ), are also provided with the first refrigerant circulation flow path (refrigeration system) for temperature regulation, the second refrigerant circulation flow path (dehumidification system) for humidity regulation, air supply electric heater 11, fresh wind electric heater 12, etc.

[0066] The difference is that in the combined evaporator 3 shared by the fins, the refrigerant heat exchange pipe 3-1 of the first refrigerant circulation flow path (refrigeration system) is placed in the refrigeration of the second refrigerant circulation flow path (dehumidification system). Before the refrigerant heat exchange pipeline 3-2, that is, the return air of the plant cabin first flows through the refrigerant evaporation heat exchange pipeline 3-1 of the refrigeration system. In this embodiment, both the refrigeration system compressor 4 of the refrigeration system and the dehumidification system comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com