On-line acoustic monitoring and diagnosis method for tooth breakage faults of planetary gearbox

A technology for planetary gearboxes and diagnostic methods, applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., to achieve the effects of accurate extraction, convenient and reliable installation, and improved convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

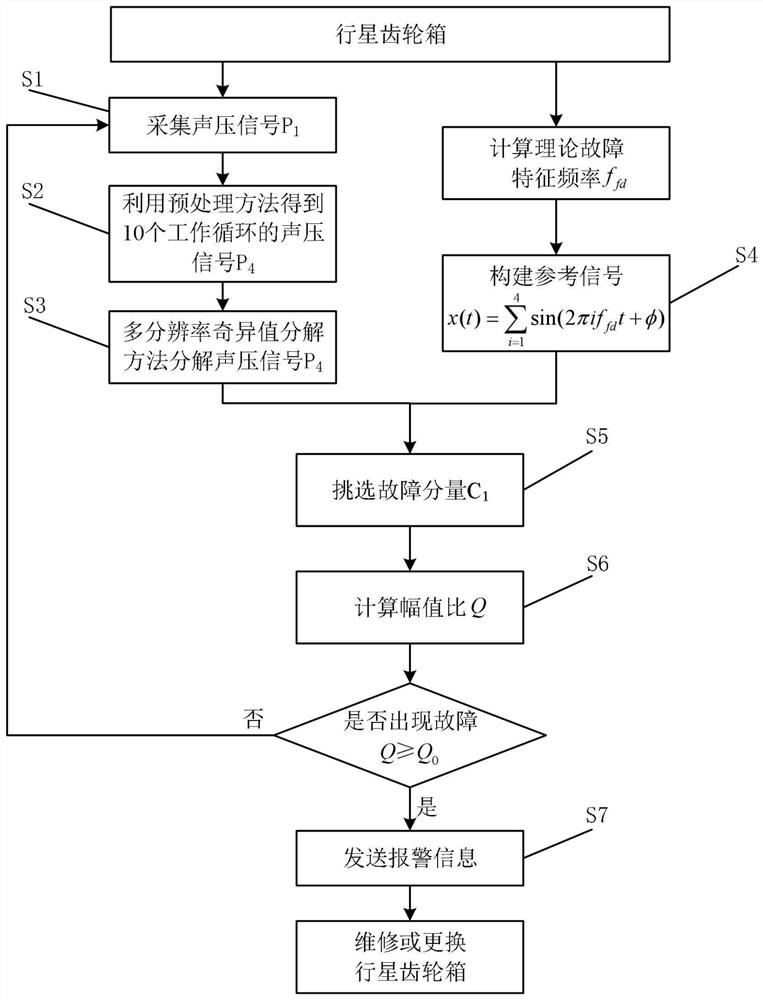

[0084] The embodiment of the present invention takes a three-stage planetary gearbox in an actual engineering application as an example, and adopts the method proposed by the present invention to perform on-line acoustic monitoring and diagnosis on the three-stage planetary gearbox, which specifically includes the following steps:

[0085] S1: Collect sound pressure signal:

[0086] Use a sound pressure sensor to measure the sound pressure signal P at a distance of 1cm from the three-stage planetary gearbox 1 , the sampling frequency is set to 25.6kHz, and the sensitivity of the sound pressure sensor is -25.8dB (0dB=1V / Pa, at 1kHz). Due to the large amount of collected test data, only part of the data is shown in Table 1;

[0087] Table 1 Sound pressure signal P 1

[0088] data point 1 2 3 4 5 6 7 8 9 P 1 (mV)

0.0397 0.0306 0.0200 0.0167 0.0186 0.0203 0.0208 0.0181 0.0116 data point 10 11 12 13 14 15 16 17 18 P 1 (mV) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com