Device for testing anti-condensation capability of material and application method

An application method and a technology of a testing device, which are applied in the direction of using material absorption and weighing, etc., can solve the problems of being unable to provide manufacturers with display effects, unable to perform actual demonstrations, and poor publicity effects, so as to achieve easy display and publicity, better display effects, The effect of reducing evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

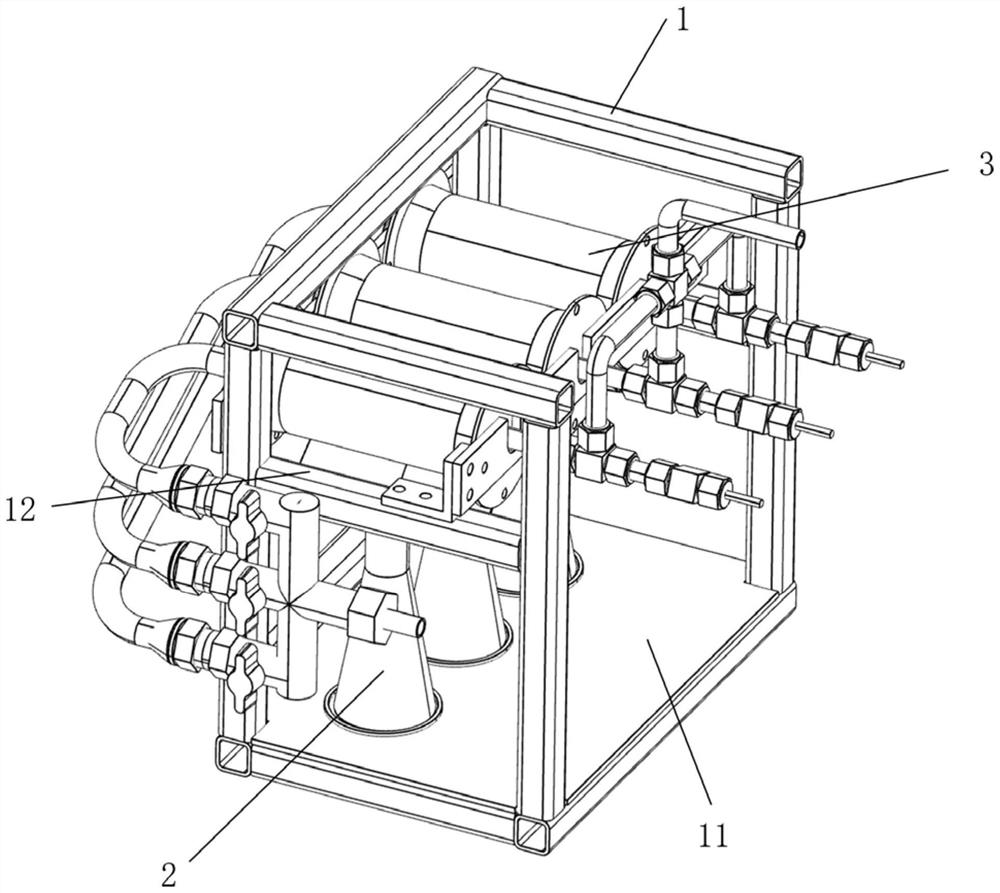

[0030] Such as figure 1 As shown, this embodiment provides a device for testing the anti-condensation ability of materials, including a fixing frame 1 , a condensation collecting module 2 and a condensation generating module 3 . The fixed frame 1 is a rectangular frame of steel structure, and a bottom plate 11 is arranged at the bottom, and a mounting rod 12 is arranged at the center of both sides. The test device is provided with at least one condensation collection module 2 and condensation generation module 3. In this embodiment, three condensation generation modules 3 arranged in parallel are preferably arranged, and the three condensation generation modules 3 are installed in the fixed frame 1 near the top. part. The number of condensation collecting modules 2 is the same as that of the condensation generating modules 3 , placed on the bottom plate 11 , and correspondingly located below the condensation generating modules 3 .

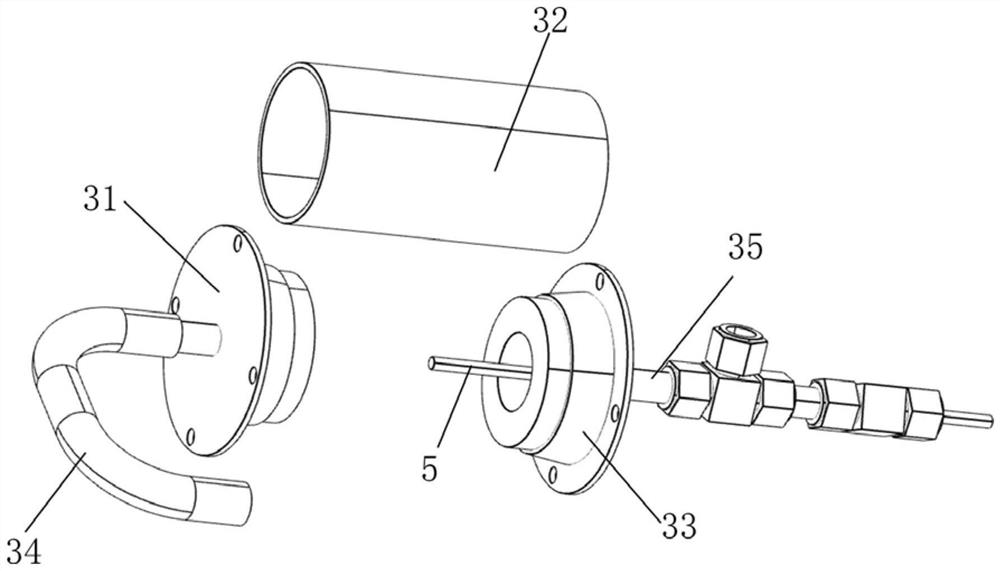

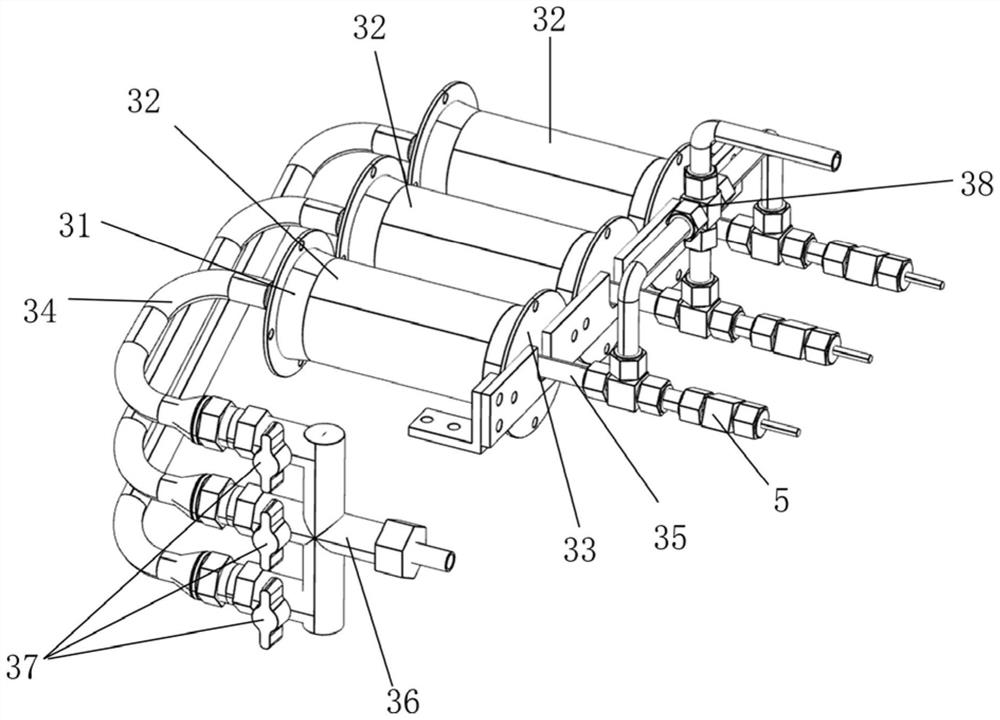

[0031] Such as figure 2 and image 3 As...

Embodiment 2

[0037] The overall structure of this embodiment is the same as that of Implementation 1, the difference is that: Figure 6 As shown, the test device also includes a constant temperature and humidity box 6, the fixed frame 1, the condensation collection module 2 and the condensation generation module 3 are placed in the constant temperature and humidity box 6 as a whole for testing and display, so as to avoid the impact of environmental temperature changes on the condensation effect. Impact. One side of constant temperature and humidity box 6 is transparent and convenient to observe. The water pipe of the chiller 4 penetrates from the outside of the constant temperature and humidity box 6 to connect to the condensation generation module 3 . In the condensation generating module 3, the outside of the first sealing joint, the second sealing joint, the water inlet pipe and the water outlet pipe all include a thermal insulation material layer, which reduces the influence of the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com