Equipment layout method and system

A layout method and equipment technology, applied in computer-aided design, special data processing applications, instruments, etc., can solve problems such as difficult to ensure the reliability of equipment layout, production capacity check of process, etc., to achieve lean layout, ensure reliability, improve Effects of Reliability and Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

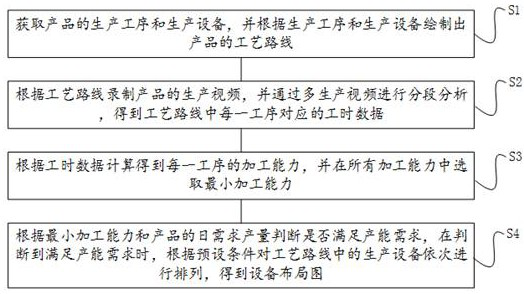

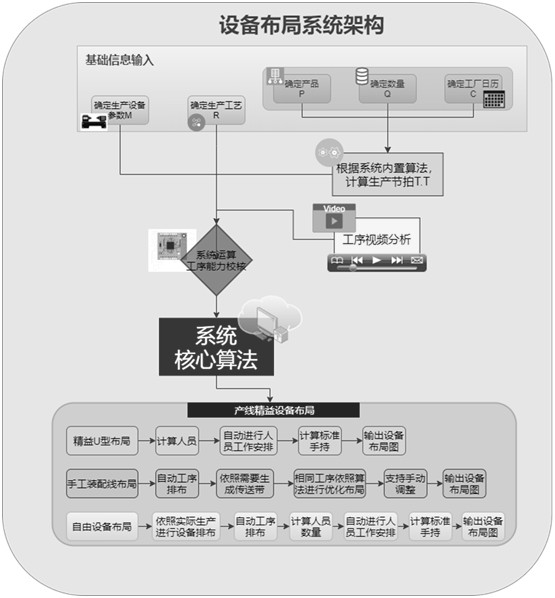

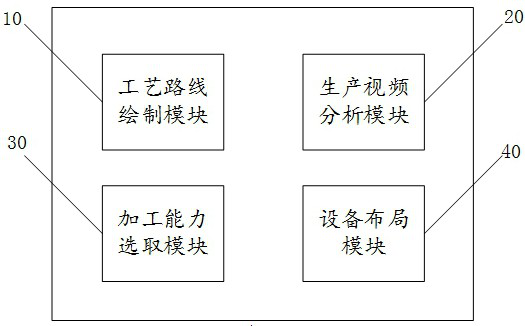

Method used

Image

Examples

specific Embodiment approach

[0068] As a specific implementation manner of the embodiment of the present invention, the device layout method further includes:

[0069] When it is judged that the capacity requirement is not met, the minimum processing capacity is greater than or equal to the daily required output by increasing the production equipment.

[0070] In the embodiment of the present invention, when it is judged that the production capacity requirement is not met, a reminder message that the production capacity requirement is not met is issued. The reminder message includes the difference between the minimum processing capacity and the daily required output, and the production equipment is correspondingly increased according to the difference so that The minimum processing capacity is greater than or equal to the daily demand output, so that the process route meets the production capacity demand. On the premise that the production capacity meets the demand, an accurate equipment layout diagram is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com