Product edge defect detection method

A technology of edge defects and detection methods, applied in neural learning methods, image data processing, instruments, etc., can solve problems such as poor stability, affecting detection accuracy and effect, relying on manual algorithm adjustment, etc., to achieve high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The present invention is described in detail below in conjunction with embodiment. In order to make the purpose, technical solutions and advantages of the present invention clearer and clearer, the present invention will be further described in detail below, but the present invention is not limited to these examples.

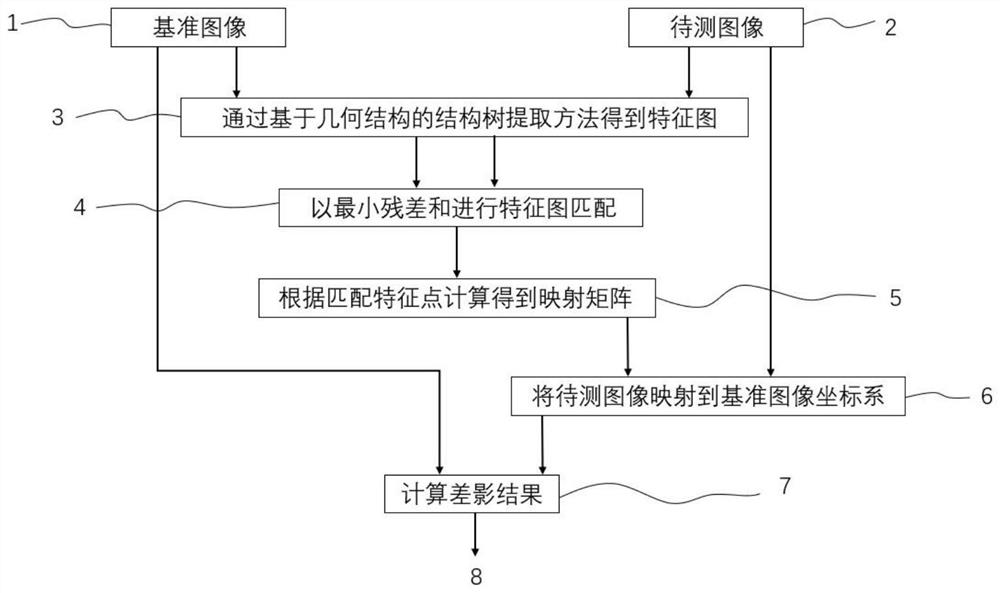

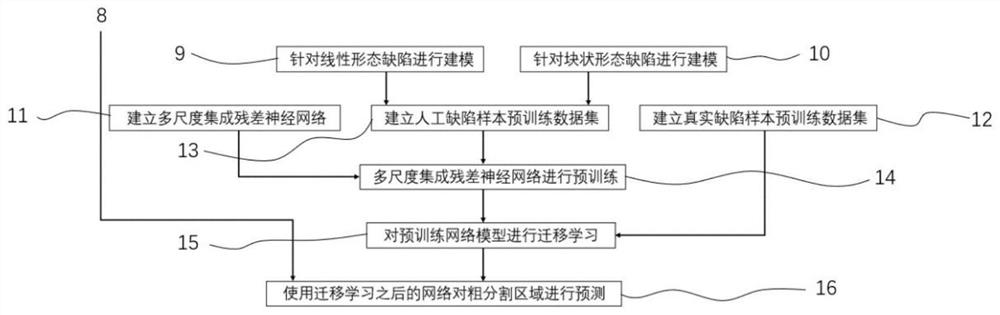

[0078] Such as figure 1 , figure 2 Shown are respectively the flow charts (upper) and (lower) of the product defect detection method described in this embodiment; figure 1 , figure 2 Combined together, a complete flow chart of the product defect detection method is formed. Among them, the specific process includes the following steps:

[0079] Step 1 image acquisition, it is necessary to acquire a complete, clear and defect-free reference image I T and the image to be tested I s . There is only one glass cover in the picture content, and there is no case of shooting multiple covers at the same time. Moreover, the outline of the glass cover is cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com