Regeneration soot blower for filter bag of dust remover

A dust collector and soot blower technology, which is applied in the fields of dispersed particle filtration, chemical instruments and methods, separation methods, etc., can solve the problems of remaining in the discharge disturbance, the soot blowing effect is deteriorated, etc., to restore performance, improve pressure, structure, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

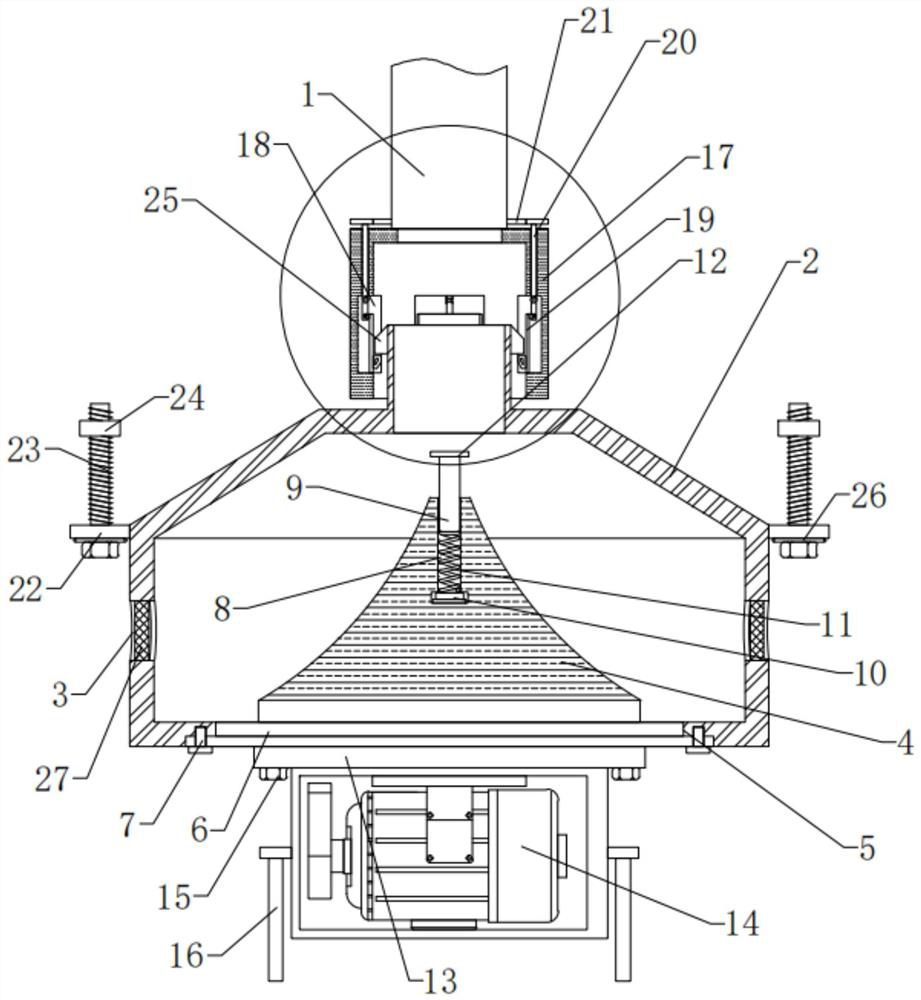

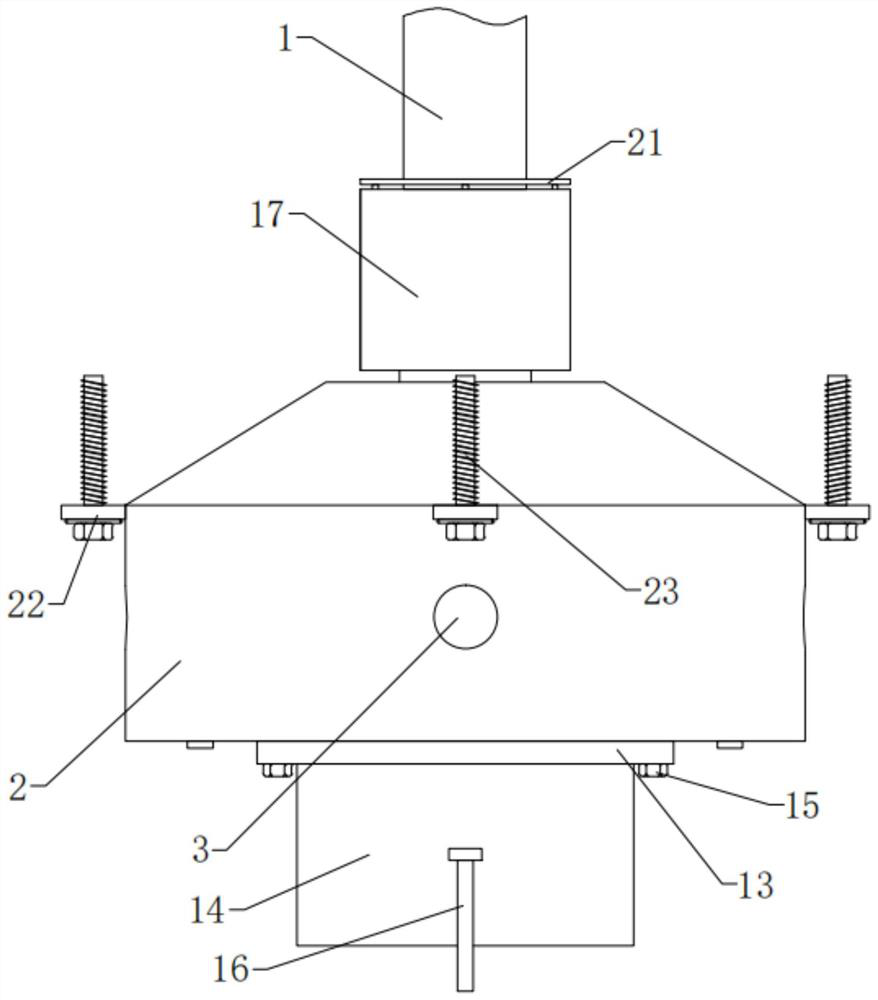

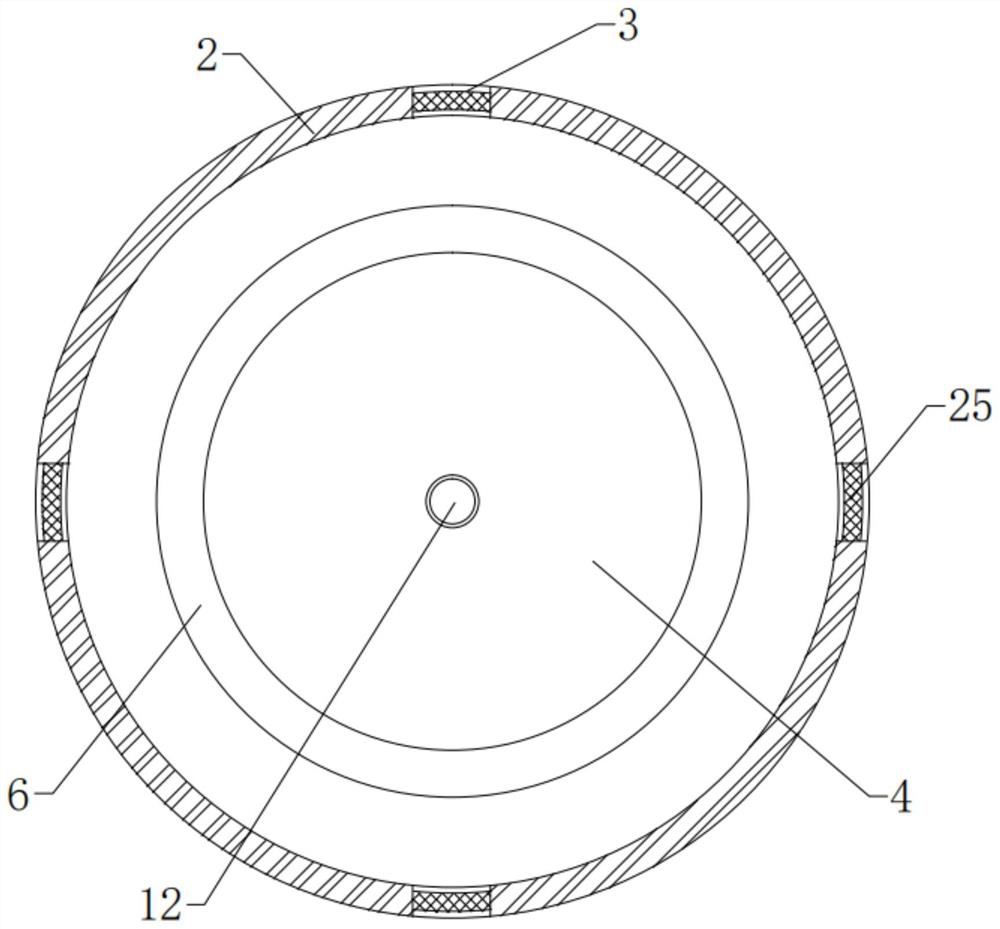

[0030] Embodiment: according to specification Figure 1-5 It can be known that this case is a regeneration soot blower for dust collector filter bags, including a gas source pipe 1, a regenerator shell 2, and a connecting assembly. The air port, the end of the gas source pipe 1 is provided with an anti-lock assembly connected to the air inlet, the regenerator shell 2 is provided with a gas diversion structure, and the bottom surface of the gas diversion structure is provided with a separate vibration structure. In the specific implementation process, The regenerator shell 2 is a thin-walled cylindrical structure with a conical top surface. Air is supplied to the regenerator shell 2 through the air source pipe 1. The air source pipe 1 is equipped with an anti-lock assembly connected to the top of the regenerator shell 2. On the air inlet of the regenerator shell 2, the regenerator is connected and fixed on the cloth bag, and the high-pressure air is passed into the regenerator ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap