Compaction device for fiber material processing

A fiber material and compaction device technology, applied in the field of fiber material processing, can solve the problems of low safety, time-consuming and labor-intensive, etc., and achieve the effect of excellent cleaning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

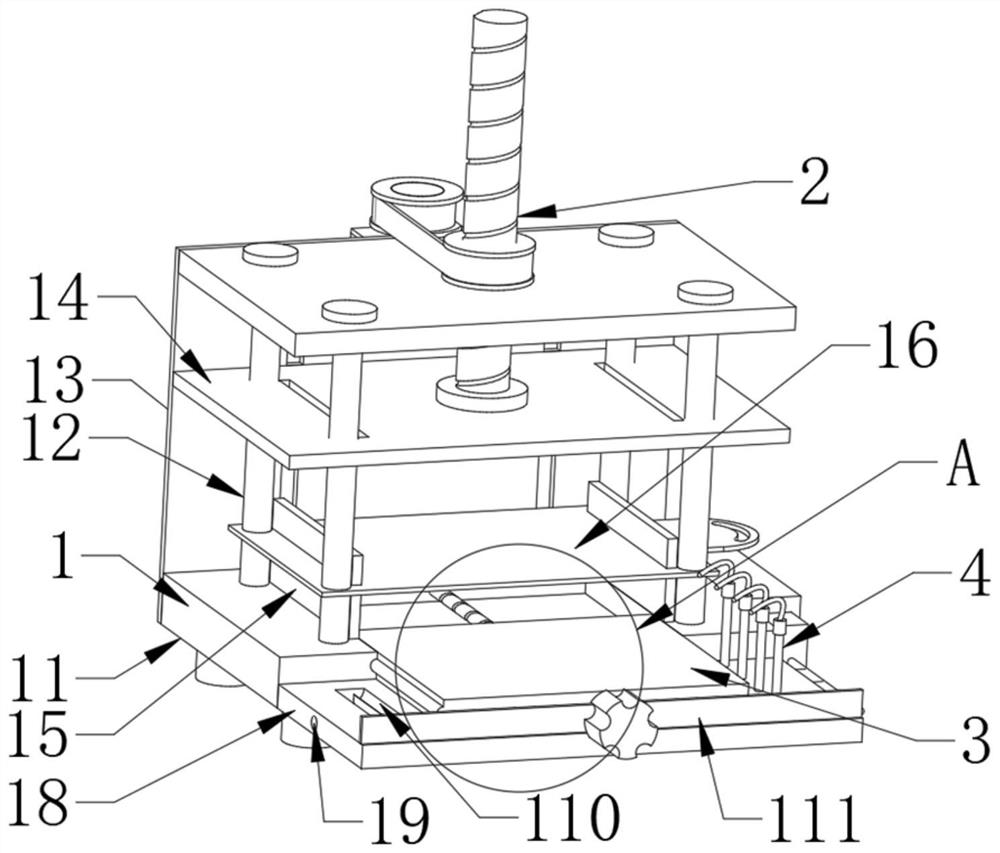

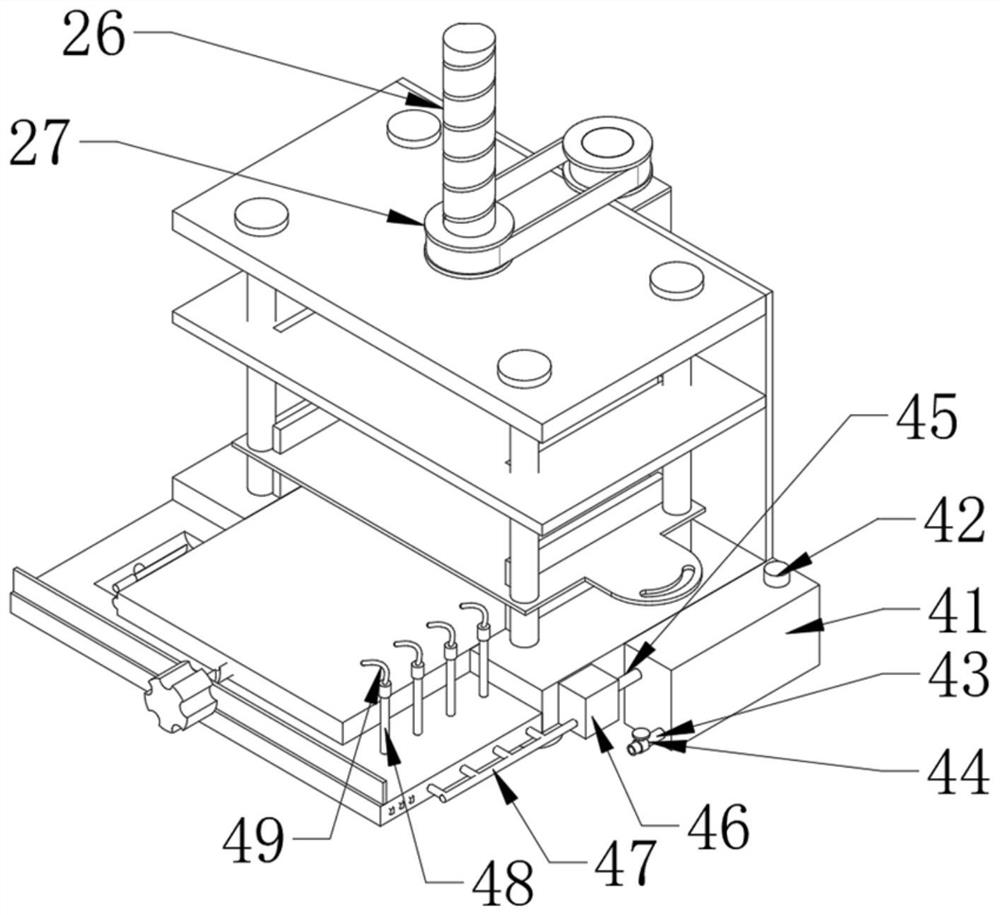

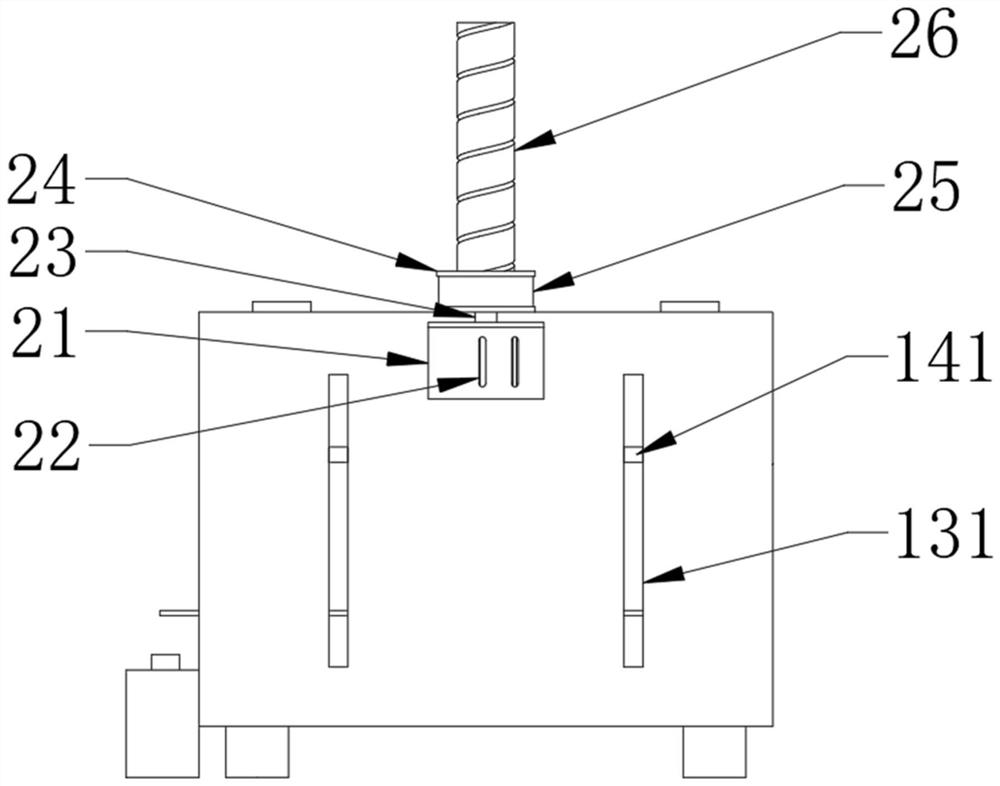

[0048] see Figure 1 to Figure 6 , this embodiment provides a compacting device for fiber material processing, including: a basic frame assembly 1, a compacting assembly 2 and a feeding assembly 3;

[0049] Such as figure 1 , image 3 with Figure 5 As shown, wherein, the basic frame assembly 1 includes a base 11, a guide rod 12, a back plate 13, a main pressure plate 14, a partition 15, an auxiliary pressure plate 16, a connecting plate 18 and a baffle plate 111, and the number of guide rods 12 is four , the four guide rods 12 are evenly distributed and fixedly connected to the top of the base 11, the number of partitions 15 is two, the two partitions 15 are symmetrically distributed and fixedly connected to the top of the base 11, the main pressure plate 14 and the guide rod 12 is slidingly connected, the back plate 13 is fixedly connected to one side of the base 11, the top of the guide rod 12 is fixedly connected to a compacted top plate, the auxiliary pressure plate 16...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap