Automatic charging robot for new energy automobile

A new energy vehicle, automatic charging technology, applied in electric vehicle charging technology, charging stations, electric vehicles, etc., can solve the problems of low degree of automation, increased manufacturing costs, personnel injuries, etc., to achieve a high degree of automation and prevent electric shock hazards. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

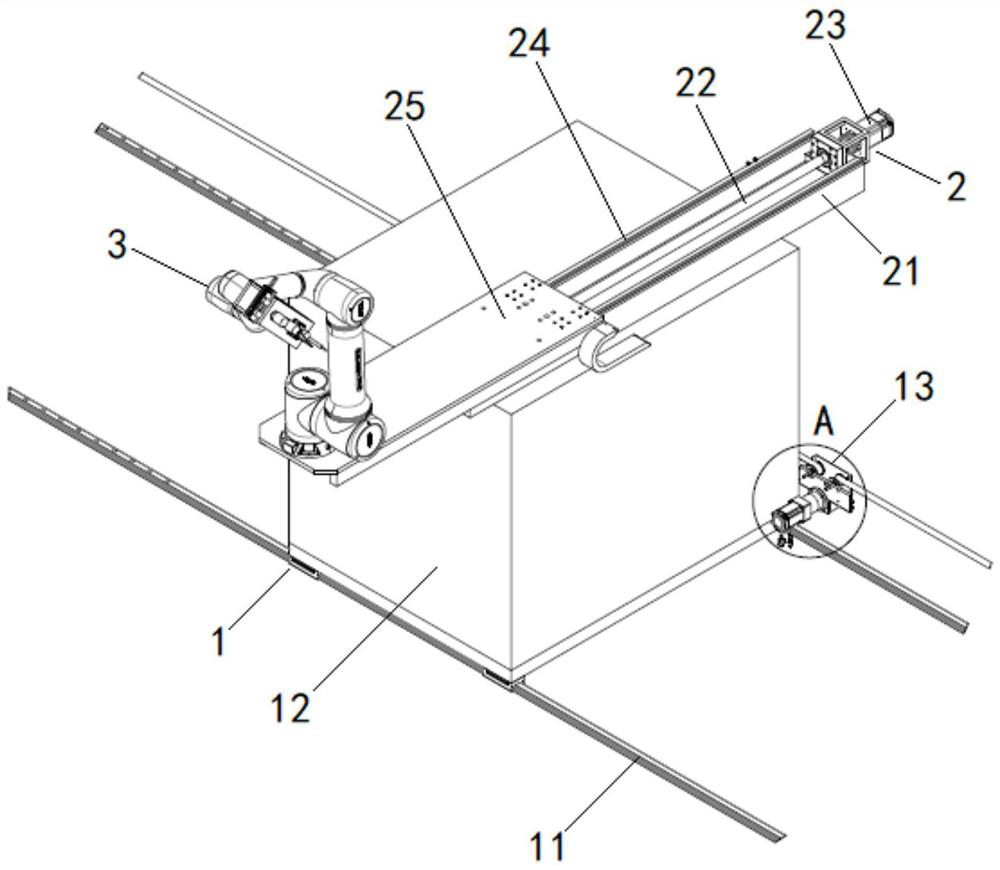

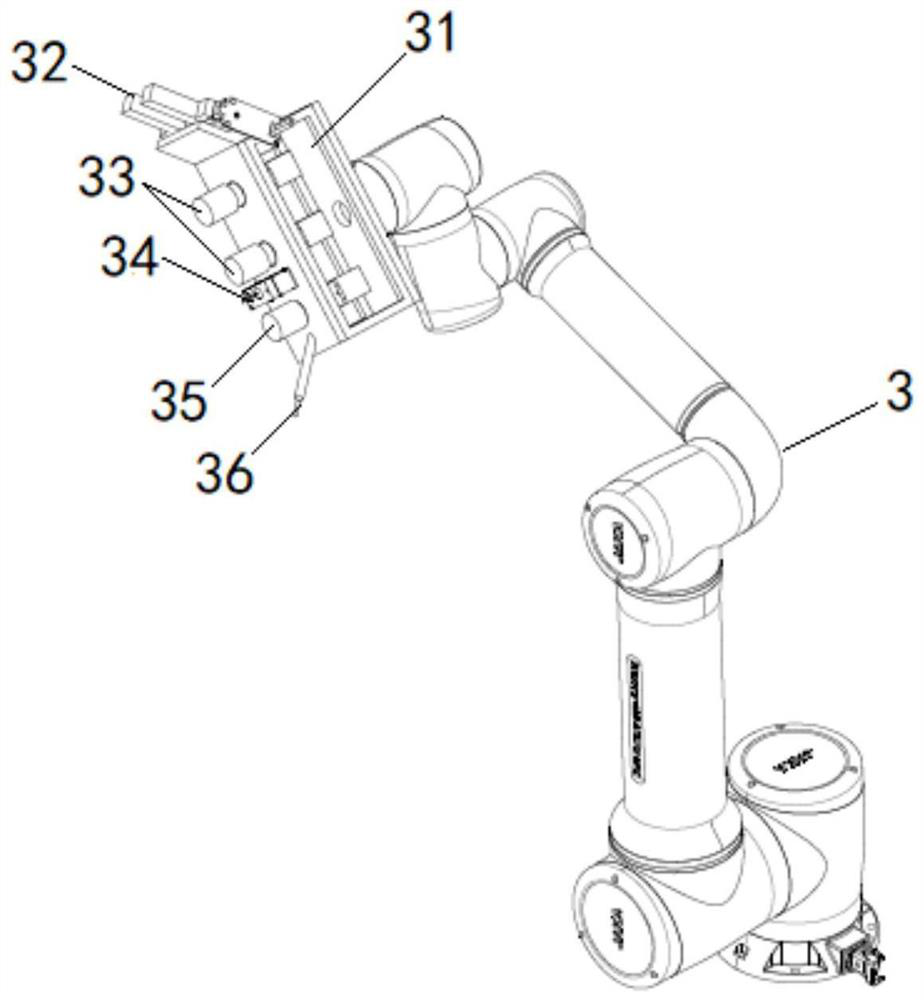

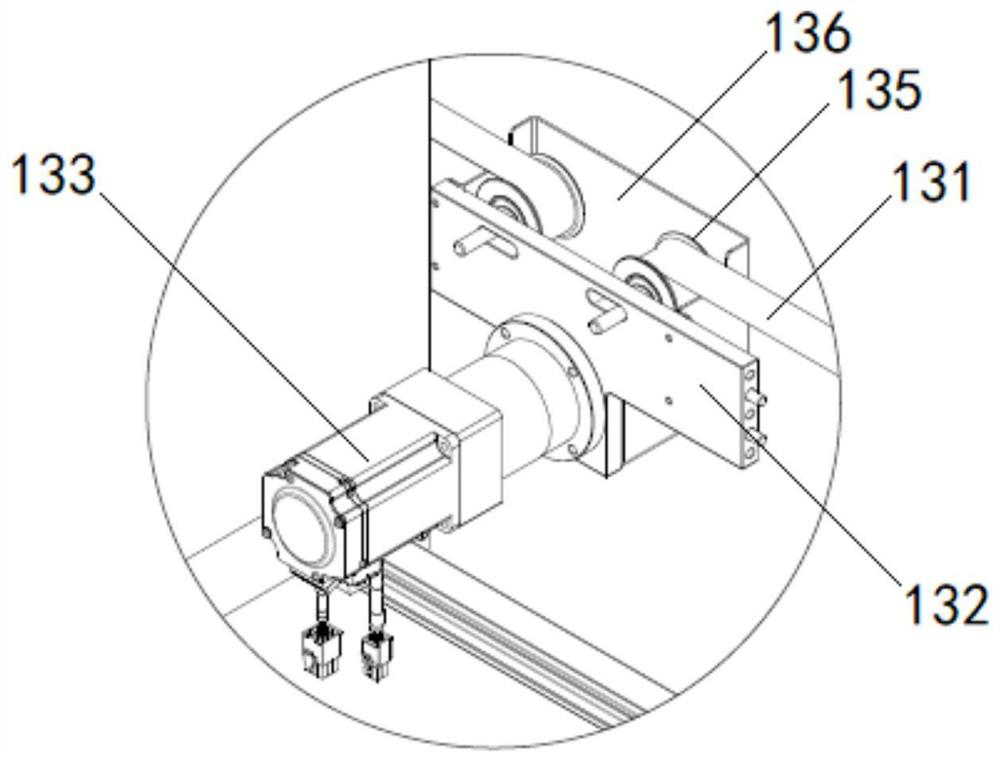

[0026] attached Figure 1-4 It is the new energy vehicle automatic charging robot described in the present invention, which includes a horizontally placed X-axis servo module 1, a Y-axis servo module arranged at the driving end of the X-axis servo module 1 and placed vertically with the X-axis servo module 1 2. The six-axis robotic arm 3 arranged at the driving end of the Y-axis servo module 2, and the mounting seat 31 provided at the driving end of the six-axis robotic arm 3; the mounting seat 31 is respectively provided with an electric gripper 32, a visual sensor, a laser displacement The sensor 34 and the switch cover finger 36; when receiving the charging signal: first drive the Y-axis servo module 2 through the X-axis servo module 1 to reach the side of the charging port of the new energy vehicle, and then drive the six-axis mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com