Passive wire climbing type aerial robot for cleaning an overhead cable

An aerial robot and overhead cable technology, which is applied to overhead line/cable equipment, rotorcraft, aircraft, etc., can solve problems such as line damage, low operating efficiency, and fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

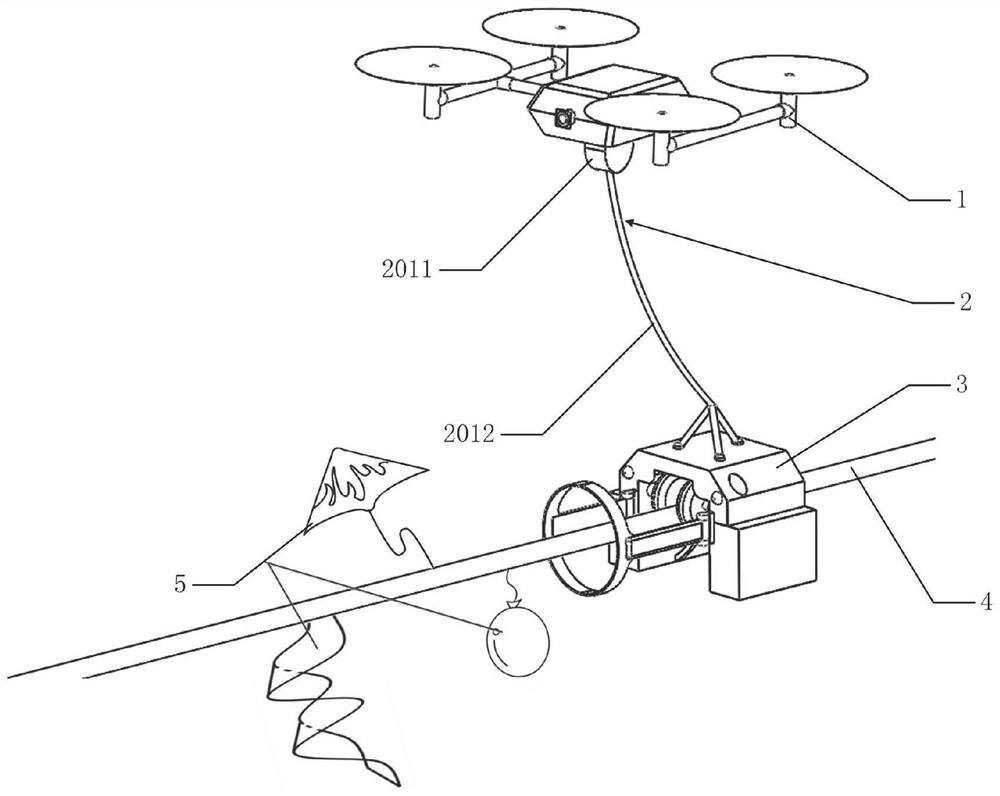

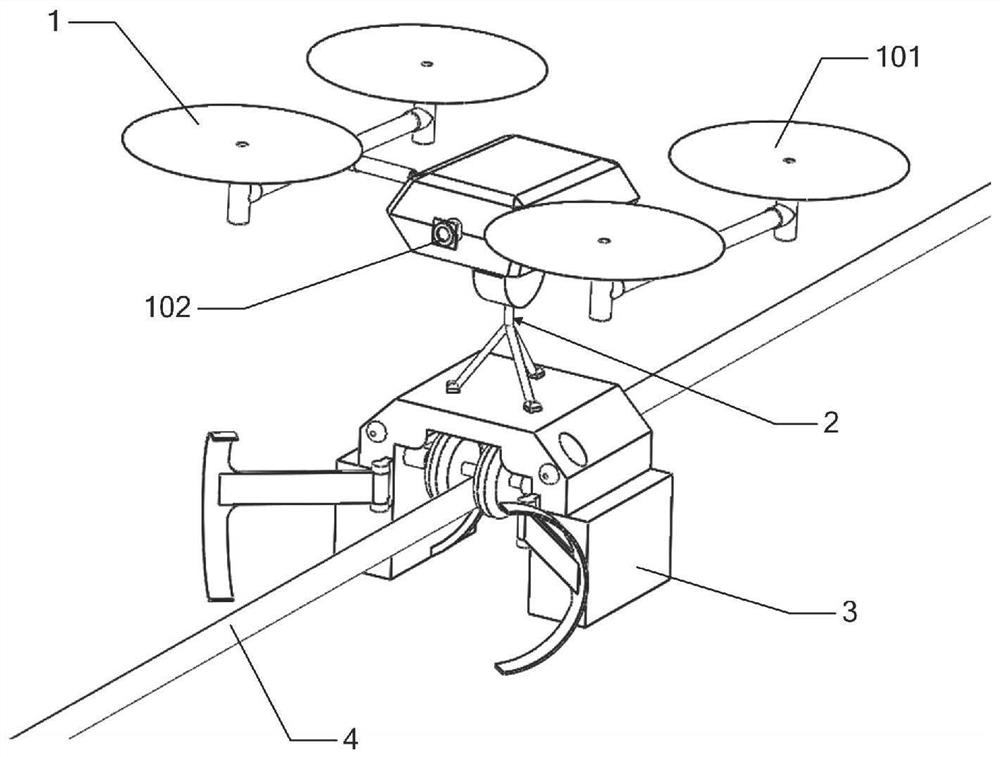

[0044] Embodiment 1: as figure 1 , figure 2 and Figure 5 to Figure 10 As shown, a passive cable-climbing overhead cable cleaning aerial robot includes a flying platform 1, a traction mechanism 2, and an online operation device 3; the flying platform 1 has a tiltable rotor 101 and a pan-tilt camera 102; the traction mechanism 2 One end is installed under the flight platform 1, and the other end is connected to the online operation device 3; the online operation device 3 is composed of an online operation body, a device interface 301, a tool interface 302, a tool turret 303, a counterweight 304, an observation camera 305, a half Annular blade 306, passive roller 307, electric buckle 308 and guide bar 309 are formed; Tool interface 302 is positioned at the both sides of the line work body of line work device 3, can connect various cleaning tools; Tool turret 303 has two, Located in front of the online working body of the online working device 3, two semi-circular blades 306 a...

Embodiment 2

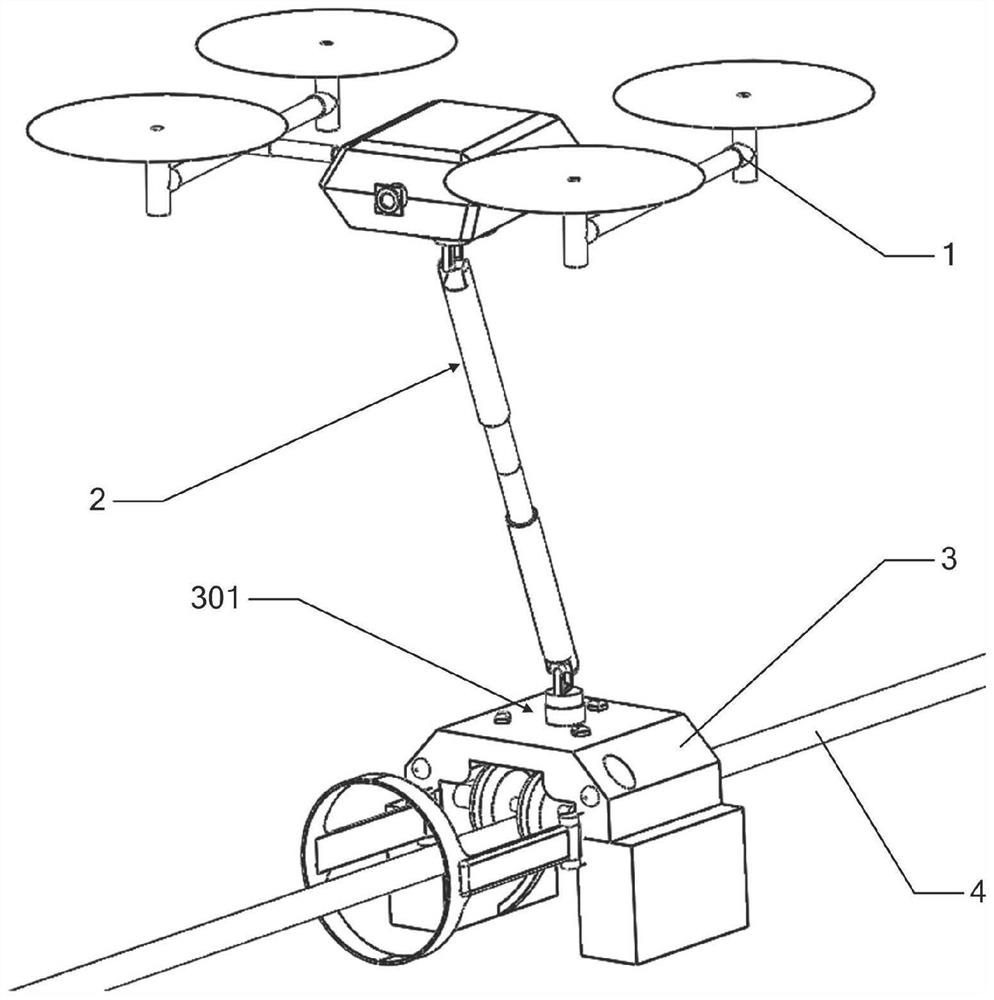

[0057] Embodiment 2: as image 3 and Figure 4 ~ Figure 9 As shown, a passive cable-climbing overhead cable cleaning aerial robot includes a flying platform 1, a traction mechanism 2, and an online operation device 3; the flying platform 1 has a tiltable rotor 101 and a pan-tilt camera 102; the traction mechanism 2 One end is installed under the flight platform 1, and the other end is connected to the online operation device 3; the online operation device 3 is composed of an online operation body, a device interface 301, a tool interface 302, a tool turret 303, a counterweight 304, an observation camera 305, a half Annular blade 306, passive roller 307, electric buckle 308 and guide bar 309 are formed; Tool interface 302 is positioned at the both sides of the line work body of line work device 3, can connect various cleaning tools; Tool turret 303 has two, Located in front of the online working body of the online working device 3, two semi-circular blades 306 are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com