Non-coplanar suspended ceiling assembly and mounting method thereof

A drop-down and suspended ceiling technology, which is applied in the drop-down ceiling assembly and its installation field, can solve the problems of heavy weight of a single top surface decorative plate, high installation difficulty coefficient, low installation efficiency of suspended ceiling, etc., and achieve flexible and multi-connection forms change, follow-up maintenance is convenient, and the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

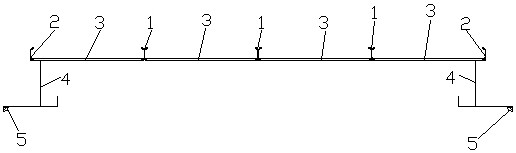

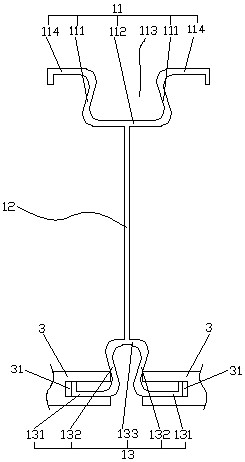

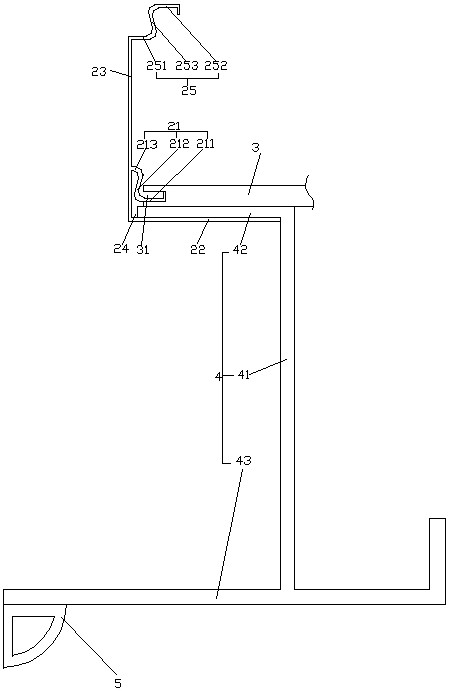

[0034] Example: such as Figure 1-3 As shown, the drop ceiling assembly includes a top trim assembly, a drop connector 2, a drop trim 4, and edge trim lines 5, wherein the top trim assembly includes a plurality of top trim 3, several The keel 1, the keel 1 is arranged between two adjacent top surface trims 3 and connects two adjacent top surface trims 3; both sides of the top surface trim 3 are provided with a card slot 31 The keel 1 includes a ceiling board connector 13, and the ceiling board connector 13 includes two clamping parts one 131 opposite to each other. - 31 are mated and connected, and the head end of the clamping part 131 is a bent structure;

[0035] The step-down connector 2 is symmetrically arranged on both sides of the top trim assembly, and includes a snap joint 21, a snap joint 21, a support plate body 22 arranged below the snap joint 21, and a support plate body 22 arranged between the support plate body 22 and the snap joint 21. The card slot 2 24 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com