Grade division testing device for explosive materials in factory building

A testing device and grade technology, applied in measuring devices, fuel testing, analyzing materials, etc., can solve problems such as loud noises and hearing impairment, and achieve the effects of reducing excessive odor, safe and convenient use, and scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

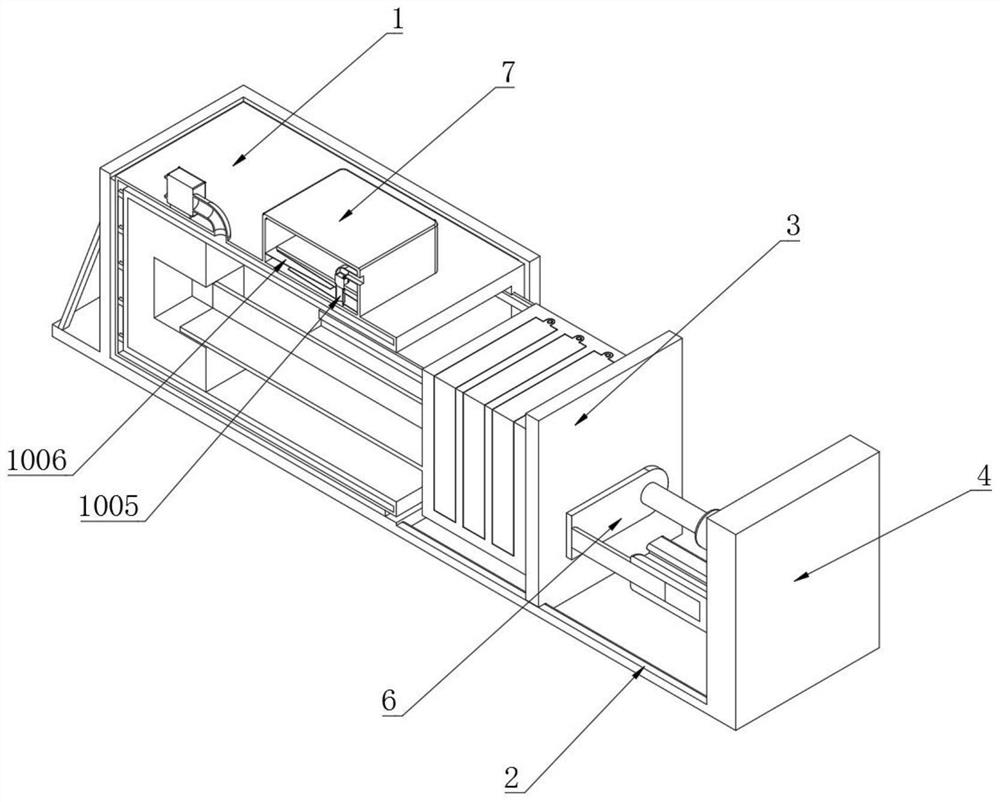

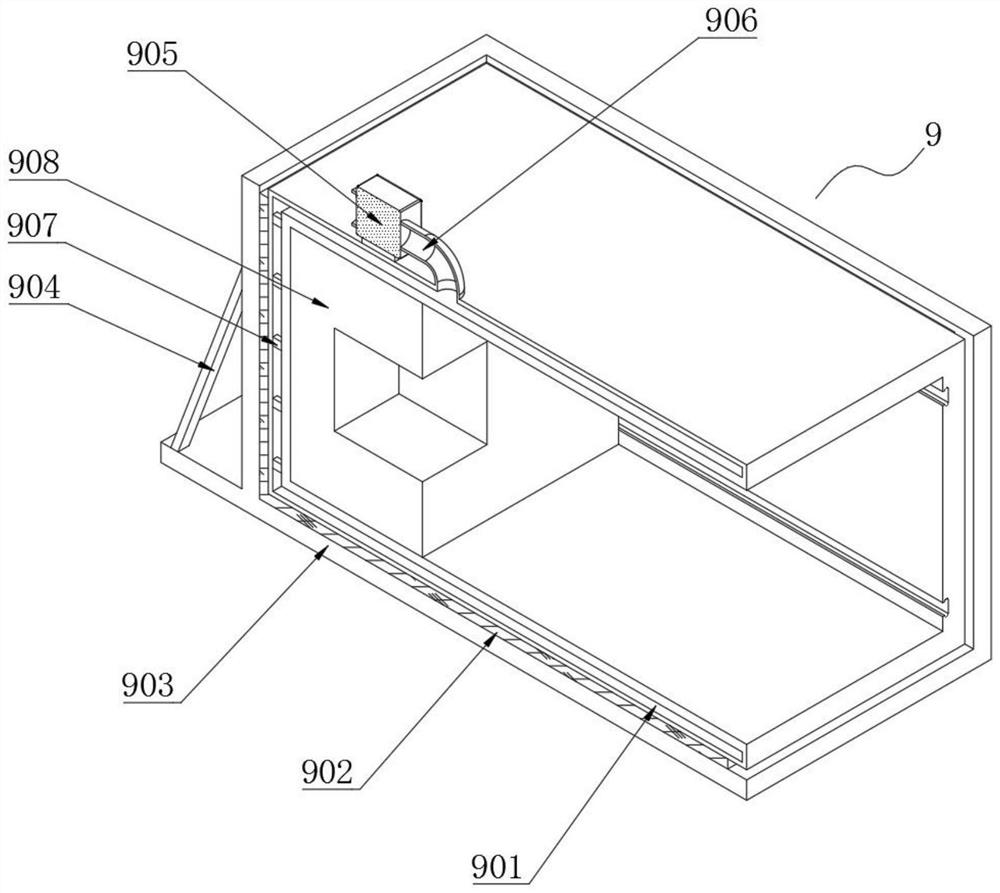

[0046] Example: such as Figure 1-7 As shown, the present invention provides a technical solution, a classification test device for explosives in a factory building, including a test box 1, the position below one side of the test box 1 is evenly connected with an installation slide rail 2, and the installation slide rail 2 A test box cover 3 is slidably installed at the upper position on the outer side, and one end of the installation slide rail 2 is connected with a fixed side plate 4, and one end of the fixed side plate 4 is evenly connected with a hydraulic telescopic rod 5, and one end of the hydraulic telescopic rod 5 is installed with a push plate 6 , the top of the test box 1 is fixedly installed with an absorption chamber 7, and the top of the absorption chamber 7 is embedded with a control switch 8;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com