Method and system for sorting chips into BIN

A chip and sorting technology, applied in image analysis, still image data clustering/classification, image data processing, etc., can solve the problems of low efficiency, long time consumption of LED chips, low precision, etc., to improve scanning resolution, improve Efficiency and the effect of improving sorting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

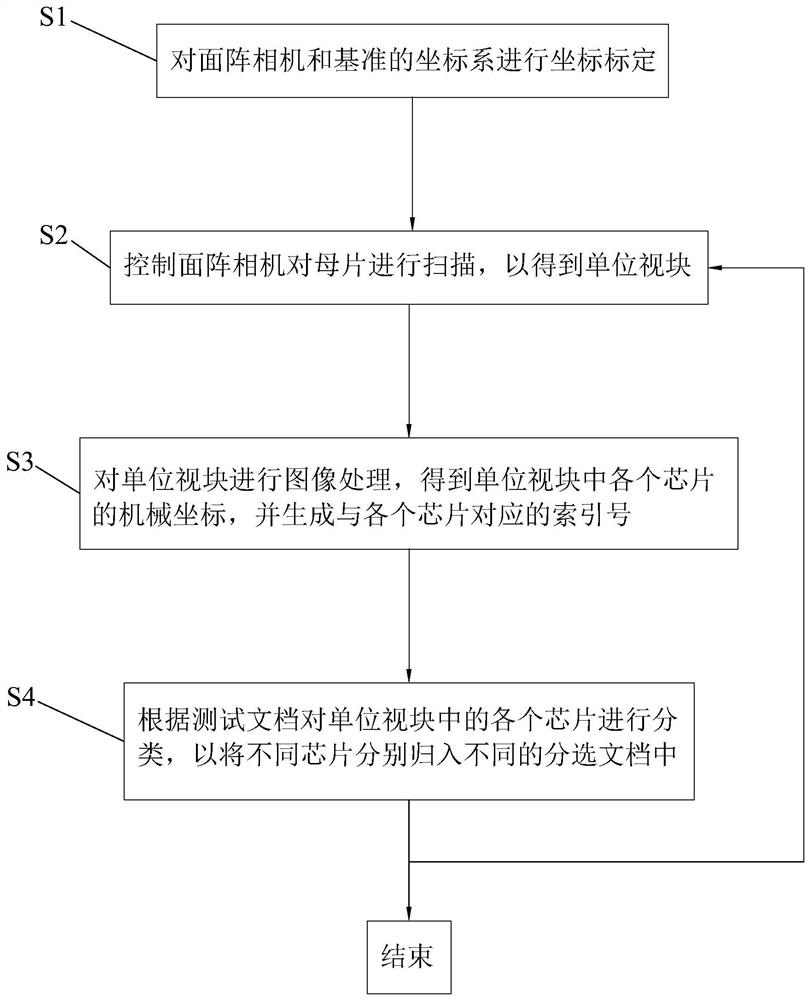

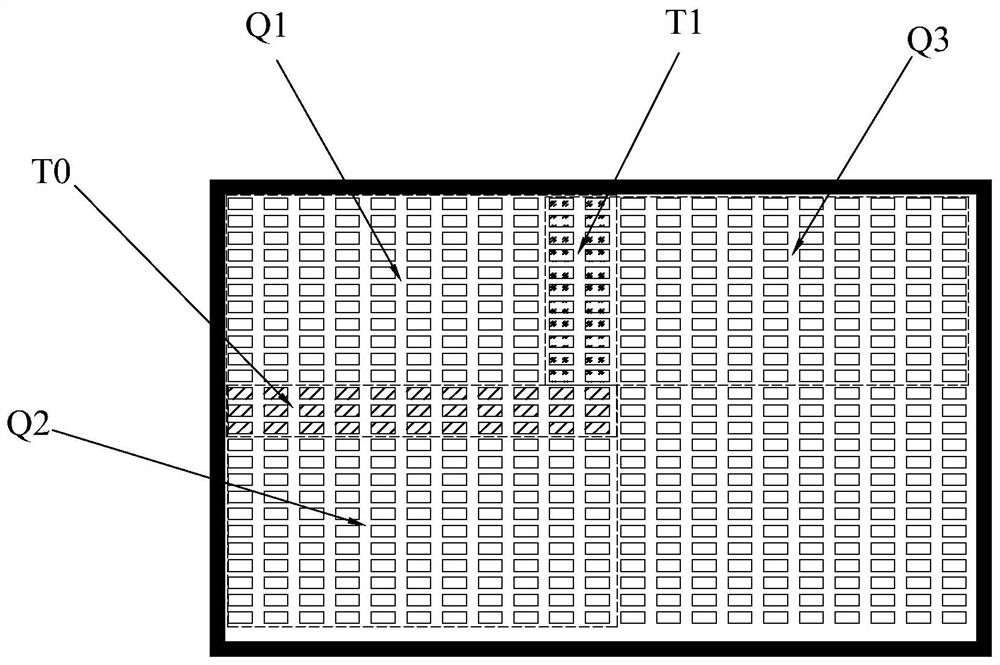

[0035] This embodiment discloses a method for chip sorting into BIN, which is used to establish a sorting document for a number of chips on the mother chip that has passed the test process and has generated test documents, especially for LED chip test sorting work, for test sorting The sorting machine provides sorting data, that is, the sorting test machine performs sorting work on each chip on the master chip according to the sorting document. In this embodiment, the master is located on a base platform, and an area array camera for area image scanning is provided, such as figure 1 , the method of sorting into BIN specifically includes:

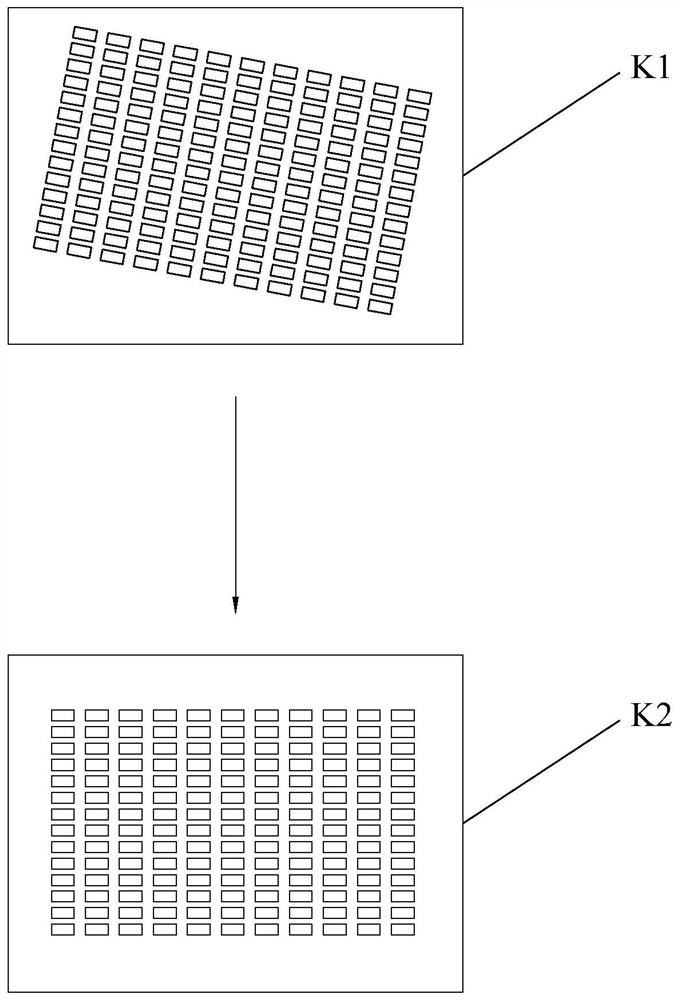

[0036] S1: Calibrate the coordinate system of the area array camera and the abutment to obtain the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com