Loudspeaker diaphragm and loudspeaker

A loudspeaker and polyetherketoneketone technology, which is applied in the field of acoustic and electric devices, can solve the problems of unfavorable speaker miniaturization, high processing temperature, and poor tensile performance, and achieve energy saving, low processing temperature, and temperature resistance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

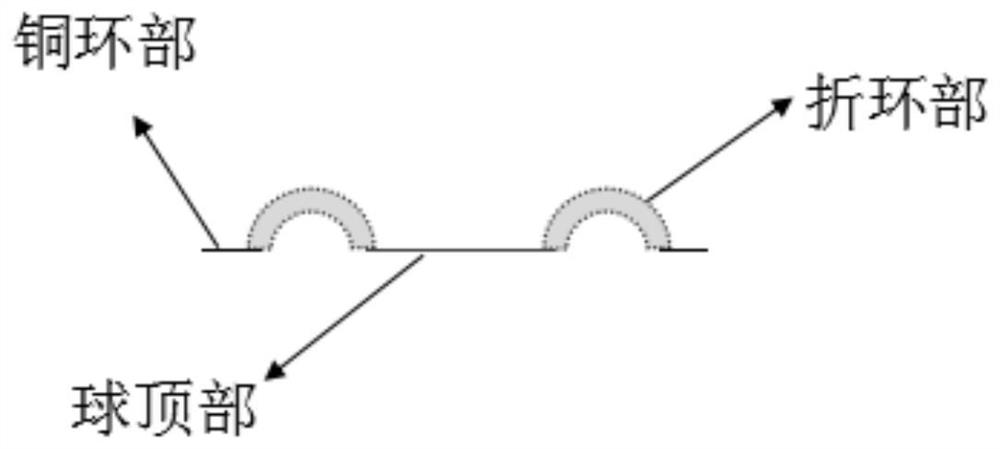

[0069] The diaphragm portion in the speaker diaphragm provided in this example is a single layer structure, which is composed of a polyetherketone material.

[0070] The polyether ketone material in Example 1 was determined by performance, as follows:

[0071] Extruder temperature 350-380 ° C (ISO 527-1BA); tensile 6% -10% (ISO 527-1BA); tensile modulus 3.8-4.0 GPa (ISO 527-1BA); tensile strength (X / Y, ie, horizontal and longitudinal) 80-100MPa, tensile strength (Z, ie vertical xy direction) 48-65MPa; Tg point 160-165 ° C; density 1.29g / cm 3 .

Embodiment 2

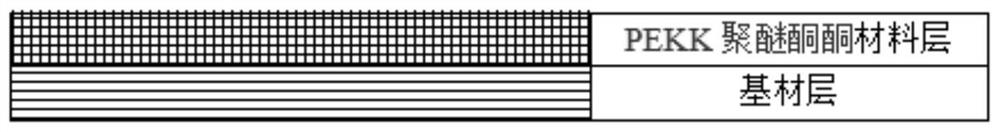

[0073] In this example, the folding ring portion in the speaker diaphragm of the speaker diaphragm is two layers of composite structures, the composite structure being composed of a layer of polyetherketate material layer and a layer of substrate layers. The structure of the folding ring figure 2 Indicated.

[0074] Among them, the material used in the substrate layer is a dynamic vulcanized rubber polyurethane elastomer TPSIV.

Embodiment 3

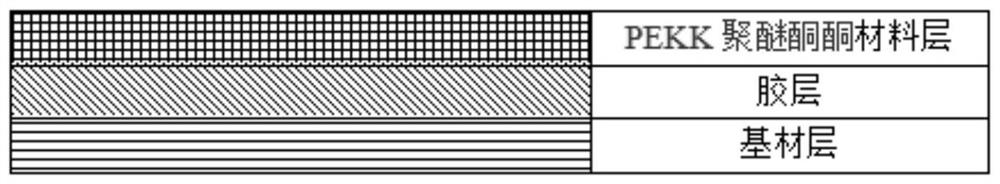

[0076] In this example, the folding ring portion in the speaker diaphragm filler film is three layers of composite structures, which is composed of a layer of polyetherketate layer, a layer of substrate layer, and a layer of rubber layer. The structure of the folding ring image 3 As shown, the rubber layer is the intermediate layer, the polyetherketate layer and the substrate layer are the top and bottom layer, respectively.

[0077] Among them, the material employed by the substrate layer is a thermoplastic polyamide elastomer TPA.

[0078] The adhesive employed by the colloated layer is a polyurethane adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com