Production and culture equipment and method based on high-quality edible mushroom strains

A technology for cultivating equipment and edible fungi, applied in botany equipment and methods, cultivation, application, etc., can solve problems such as incomplete sealing of paraffin, lowering the quality of edible fungi, loss of inoculum, etc., to achieve overall temperature balance and avoid over-temperature High, the effect of preventing the loss of bacterial fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

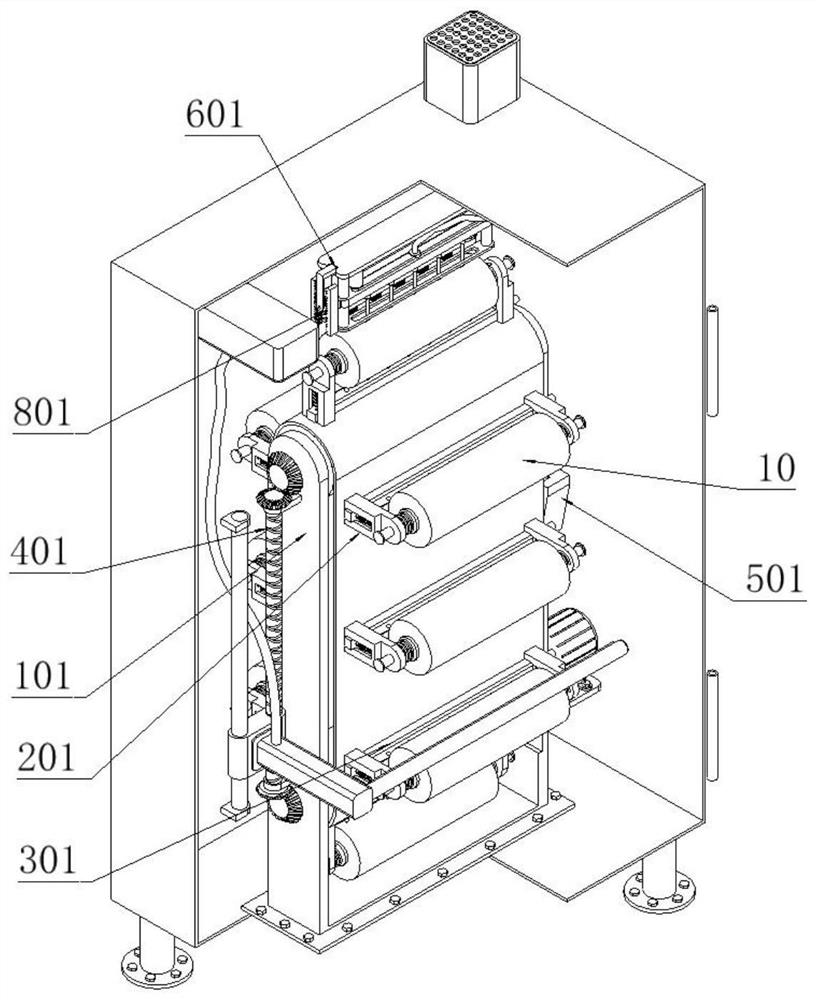

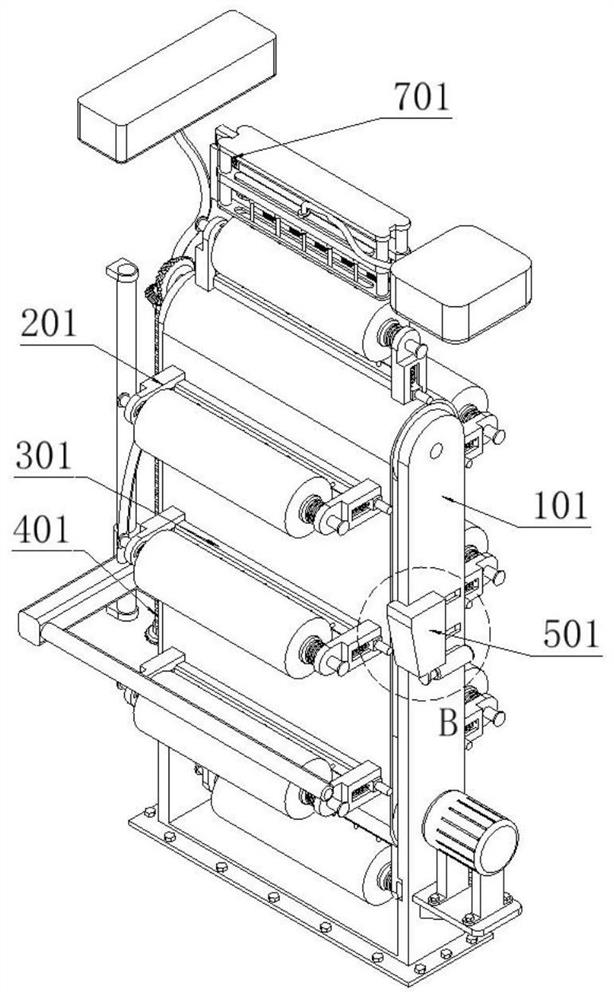

[0077] as attached figure 1 to attach Figure 12 Shown:

[0078] The present invention provides a production and cultivation equipment based on high-quality edible fungus strains, including a support device 1; the support device 1 is fixedly connected to the inside of the incubator 9, and the incubator 9 is provided with a humidification pump and an inoculation pump; Eight sets of bacterial stick positioning parts 2 are fixedly connected to the support device 1, and the eight sets of bacterial stick positioning parts 2 are all inserted with bacterial sticks 10; the eight groups of bacterial stick positioning parts 2 are all slidingly inserted with linkage ventilation devices 3; The supporting device 1 is fixedly connected with a circulation humidifying part 4; the side of the supporting device 1 is slidingly connected with a ventilating driving part 5; the inoculation device 6 is fixedly connected with the top side of the incubator 9; drive unit 7.

[0079] as attached Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com