Heat supply system heat slow-release method

A heating system and heat technology, used in heating systems, heating methods, household heating, etc., can solve the problems of time-consuming and laborious, heat exchanger damage, affecting the efficiency of the process flow, etc., to reduce production costs and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

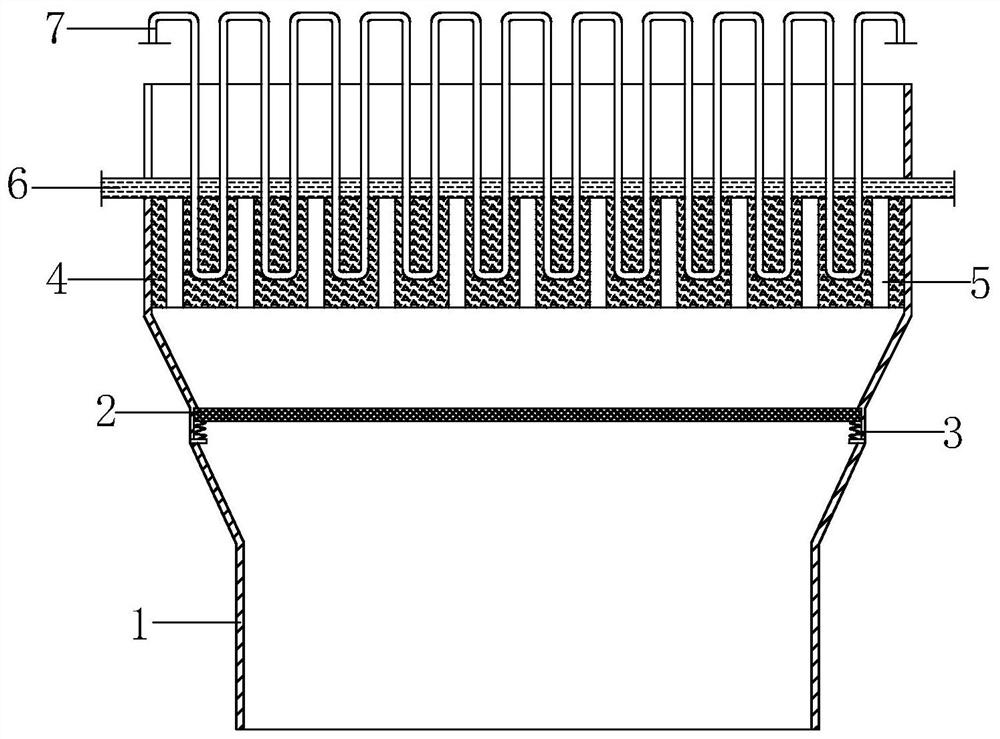

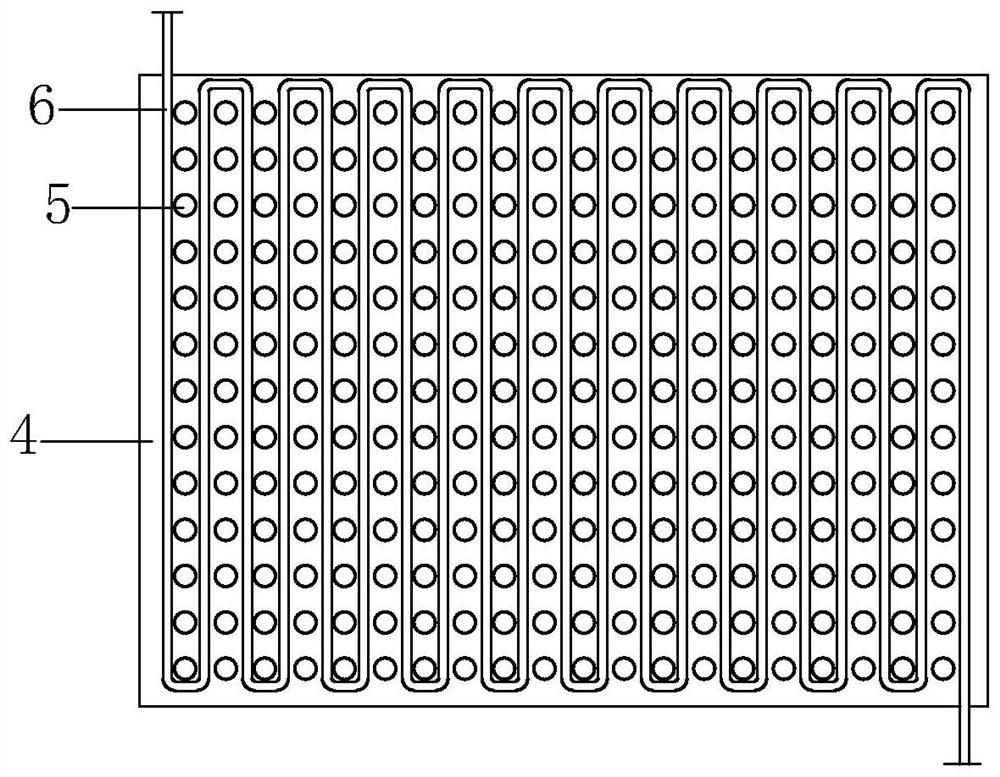

[0018] Specific implementation mode one: as Figure 1 ~ Figure 2 As shown, the present invention discloses a method for slow release of heat in a heating system. The method passes through a wide-mouth pipe 1, a filter plate 2, a phase change material layer 4, a first cooling water pipe network 6, a second cooling water pipe network 7 and It is realized by two springs 3, the narrow mouth end of the wide-mouth pipe 1 is the air inlet end, and is fixedly communicated with the outlet end of the boiler exhaust pipe through a flange, and the wide-mouth end of the wide-mouth pipe 1 is the air outlet end. It is fixedly connected with the exhaust gas treatment device through a flange, and the gas outlet end is provided with a phase change material layer 4 and a first cooling water pipe network 6, and the phase change material layer 4 is provided with a plurality of ventilation holes 5 through its thickness direction And the outer wall is fixedly connected to the inner wall of the wide-...

specific Embodiment approach 2

[0026] Specific implementation mode two: as figure 2 As shown, this embodiment is a further description of Embodiment 1, and the plurality of ventilation holes 5 are arranged in an array.

specific Embodiment approach 3

[0027] Specific implementation mode three: as figure 1 , 2 As shown, this embodiment is a further description of Embodiment 2, and each cooling water pipe of the first cooling water pipe network 6 and the second cooling water pipe network 7 is arranged at equal intervals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com