A method for slow release of heat in a heating system

A heating system and heat technology, applied in heating systems, heating methods, household heating, etc., can solve problems such as time-consuming and labor-intensive, heat exchanger damage, increased production costs, etc., to achieve the effect of reducing production costs and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

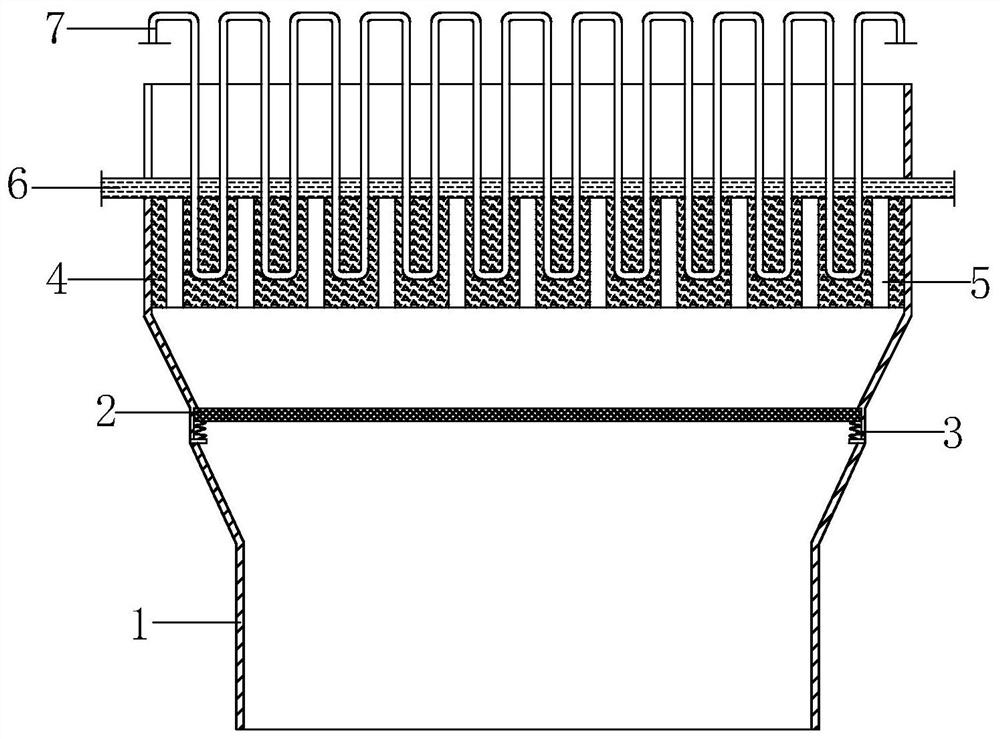

[0018]DETAILED DESCRIPTIONFigure 1 ~ 2As shown, the present invention discloses a heat relief method of heating system, which passes through the port tube 1, the filter plate 2, the phase change material layer 4, the first cooling water pipe network 6, the second cooling water pipe network 7 and The two spring 3 is realized, the narrow port end of the gate tube 1 is inlet, and the air-opening is fixedly provided by the outlet of the boiler exhaust pipe, and the port of the gate tube 1 is an extra gas end. The discharge is provided with the exhaust gas treatment device, which is provided with a phase change material layer 4 and a first cooling water pipe network 6 in the air end. The phase change material layer 4 is provided with a plurality of vent 5 in the thickness direction. Further, the outer wall is fixed to the inner wall of the gate tube 1, the first cooling water pipe network 6 is fixedly disposed on the upper end of the phase change material layer 4 and the inlet end and th...

specific Embodiment approach 2

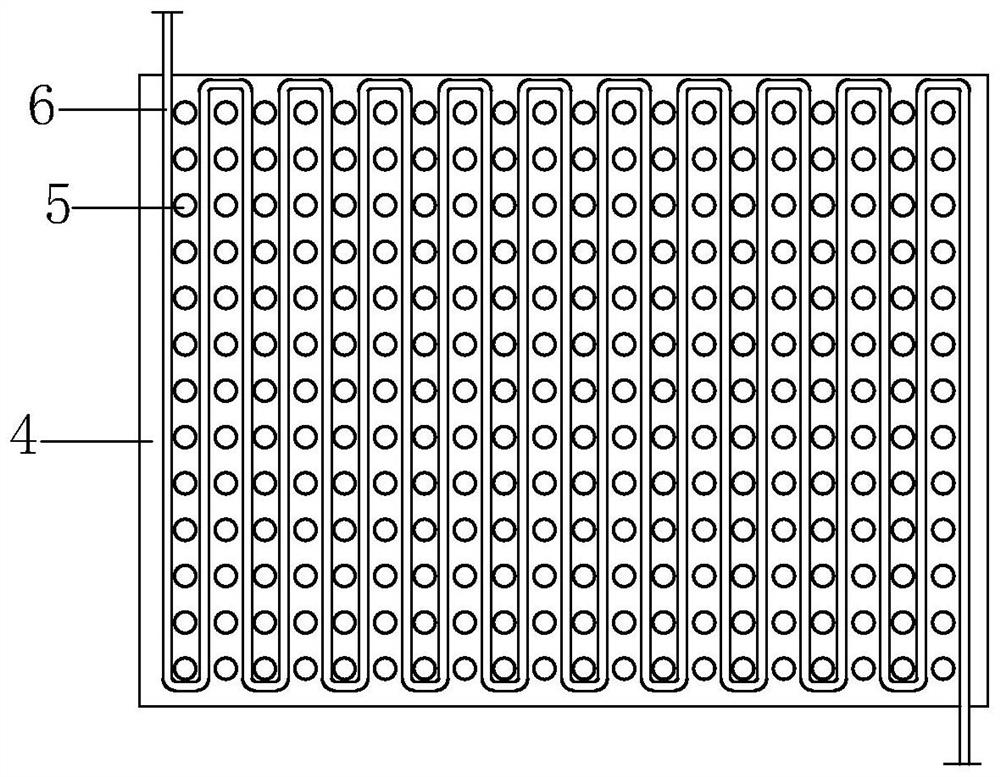

[0026]Detailed Embodiment 2:figure 2 As shown, the present embodiment is a further description of the specific embodiment, and the plurality of vents 5 array settings.

specific Embodiment approach 3

[0027]Specific Embodiment 3: Iffigure 1 ,2As shown, the present embodiment is a further explanation of the first cooling water pipe network 6 and the second cooling water pipe network 7 and the second cooling water pipe network 7 are equal to equal spacing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com