Fountain pen wiper ink recovery device for early-stage analysis of software development

A software development and recycling device technology, applied in heating devices, cleaning methods using liquids, cleaning methods and utensils, etc., can solve problems such as waste of pen wipes, cleaning collection, environmental pollution, etc. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

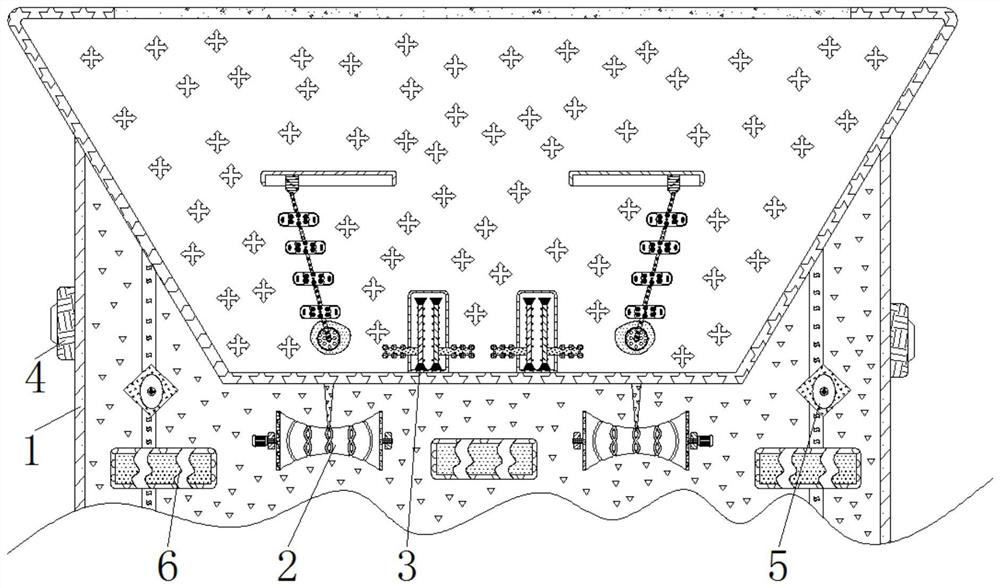

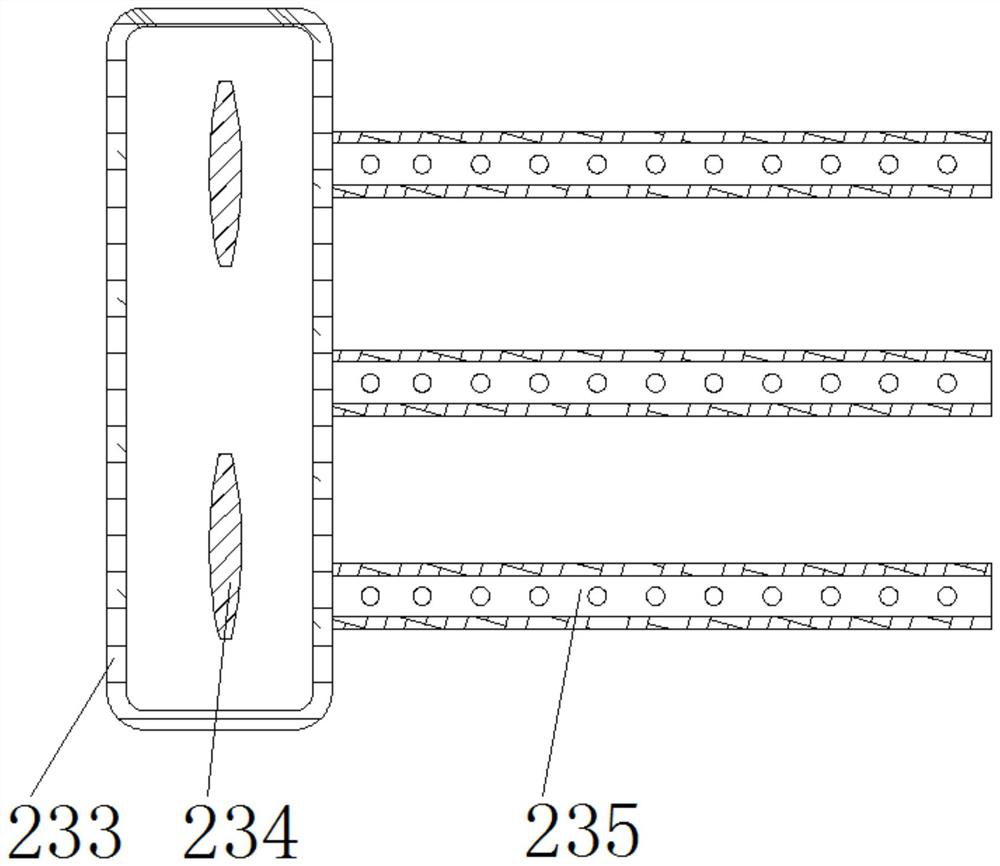

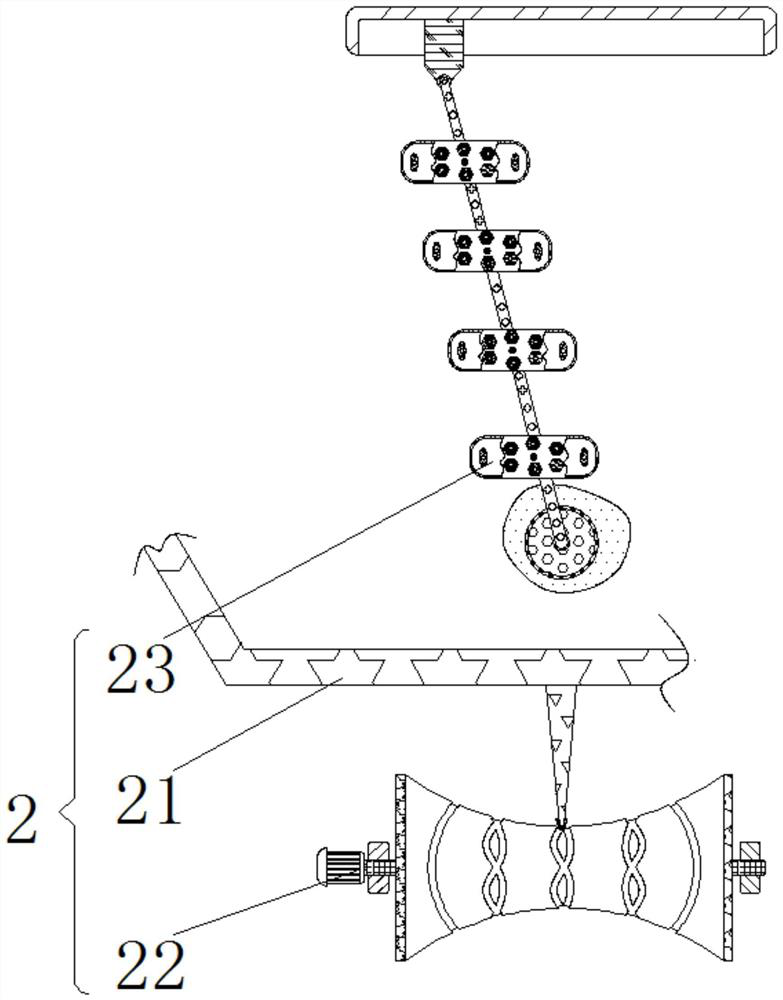

[0027] see Figure 3-7 , a water pen eraser ink recovery device used for analysis in the early stage of software development, comprising a shell 1, the inside of the shell 1 is movably connected with a cleaning mechanism 2, and the cleaning mechanism 2 includes a thermal insulation chamber 21 for accommodating a water pen eraser, and a transmission for motion adjustment Component 22 , the mixing component 23 for cleaning and separating out ink, the heat insulation chamber 21 is fixedly connected to the inner side of the housing 1 , the transmission component 22 is movably connected to the inside of the housing 1 , and the mixing component 23 is movably connected to the inside of the heat insulation chamber 21 .

[0028] The transmission assembly 22 includes a motor 221, a reciprocating rod 222, a movable groove 223, a slider 224, and a connecting rod 225. The motor 221 is fixedly connected to the inside of the casing 1, the reciprocating rod 222 is movably connected to the insi...

Embodiment 2

[0032] see Figure 8 , a water pen eraser ink recovery device used for analysis in the early stage of software development, comprising a shell 1, the inside of the shell 1 is movably connected with a cleaning mechanism 2, and the cleaning mechanism 2 includes a thermal insulation chamber 21 for accommodating a water pen eraser, and a transmission for motion adjustment Component 22 , the mixing component 23 for cleaning and separating out ink, the heat insulation chamber 21 is fixedly connected to the inner side of the housing 1 , the transmission component 22 is movably connected to the inside of the housing 1 , and the mixing component 23 is movably connected to the inside of the heat insulation chamber 21 .

[0033] The inside of the heat insulation chamber 21 is movably connected with a heating mechanism 3. The heating mechanism 3 includes an installation shell 301, a resistance plate 302, and a heating rod 303. The installation shell 301 is fixedly connected to the inside o...

Embodiment 3

[0036] see Figure 1-8, a water pen eraser ink recovery device used for analysis in the early stage of software development, comprising a shell 1, the inside of the shell 1 is movably connected with a cleaning mechanism 2, and the cleaning mechanism 2 includes a thermal insulation chamber 21 for accommodating a water pen eraser, and a transmission for motion adjustment Component 22 , the mixing component 23 for cleaning and separating out ink, the heat insulation chamber 21 is fixedly connected to the inner side of the housing 1 , the transmission component 22 is movably connected to the inside of the housing 1 , and the mixing component 23 is movably connected to the inside of the heat insulation chamber 21 .

[0037] The transmission assembly 22 includes a motor 221, a reciprocating rod 222, a movable groove 223, a slider 224, and a connecting rod 225. The motor 221 is fixedly connected to the inside of the casing 1, the reciprocating rod 222 is movably connected to the insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com