Rapid garbage degradation equipment

A rapid degradation and garbage technology, applied in metal processing, grain processing, cleaning methods and utensils, etc., can solve the problems of poor hygiene and low degradation efficiency, and achieve the effect of increasing the degradation speed, increasing the speed of degradation, and facilitating the degradation of waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

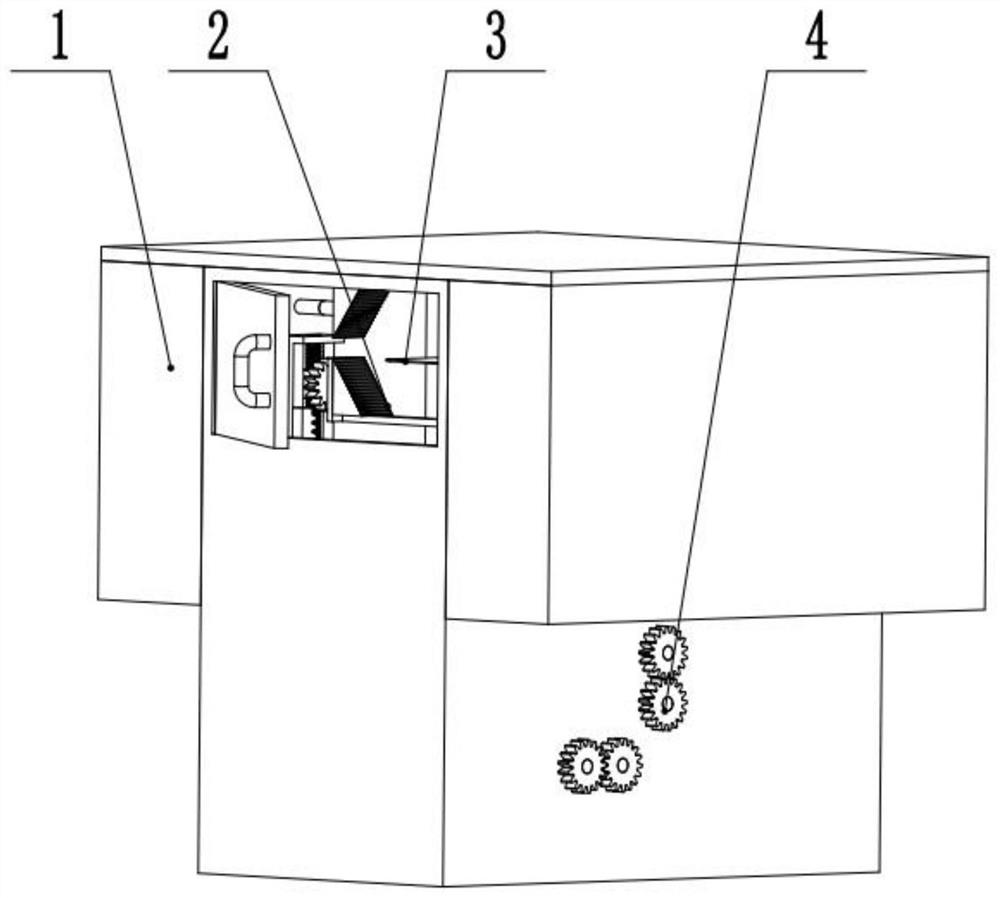

[0024] A rapid waste degradation device includes a box mechanism 1, a blanking mechanism 2 arranged inside the box mechanism 1, a cutting mechanism 3 connected to the blanking mechanism 2, and a crushing and degrading mechanism 4.

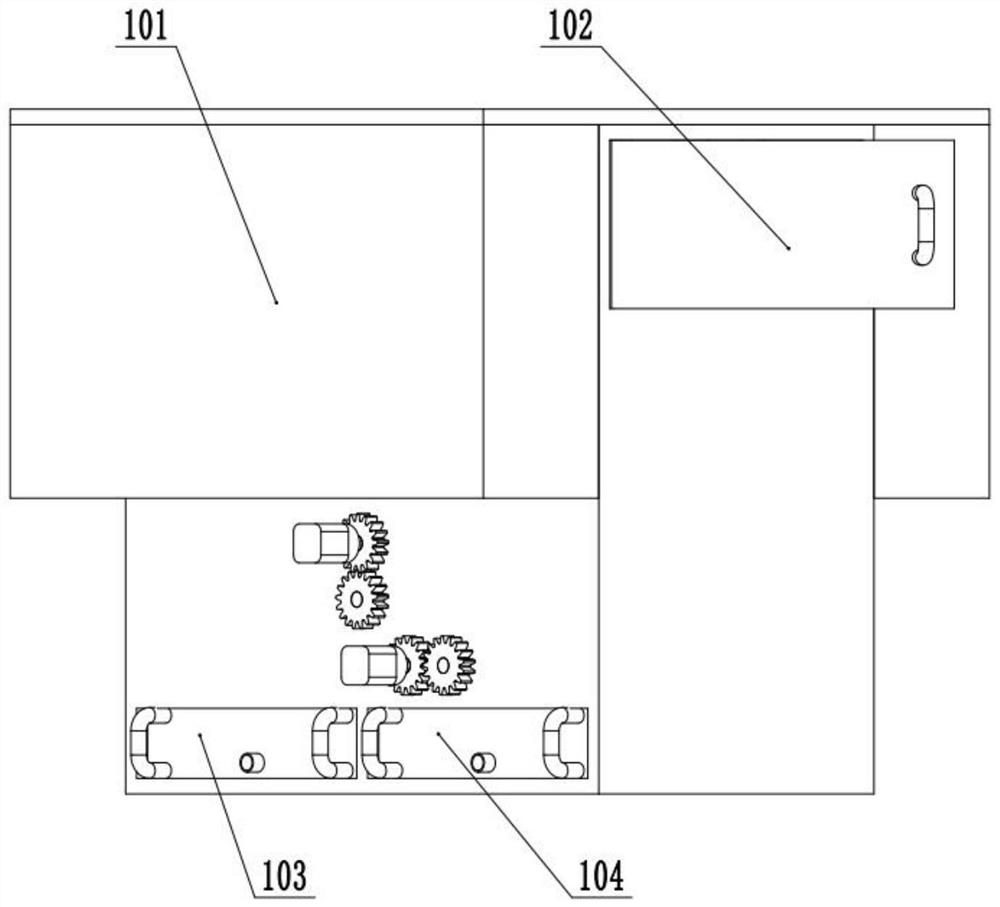

[0025] The box body mechanism 1 is provided with a box body 101 , a box door 102 , and a lunch box degradation tank 103 and a food degradation tank 104 for placing degradants under the crushing degradation mechanism 4 .

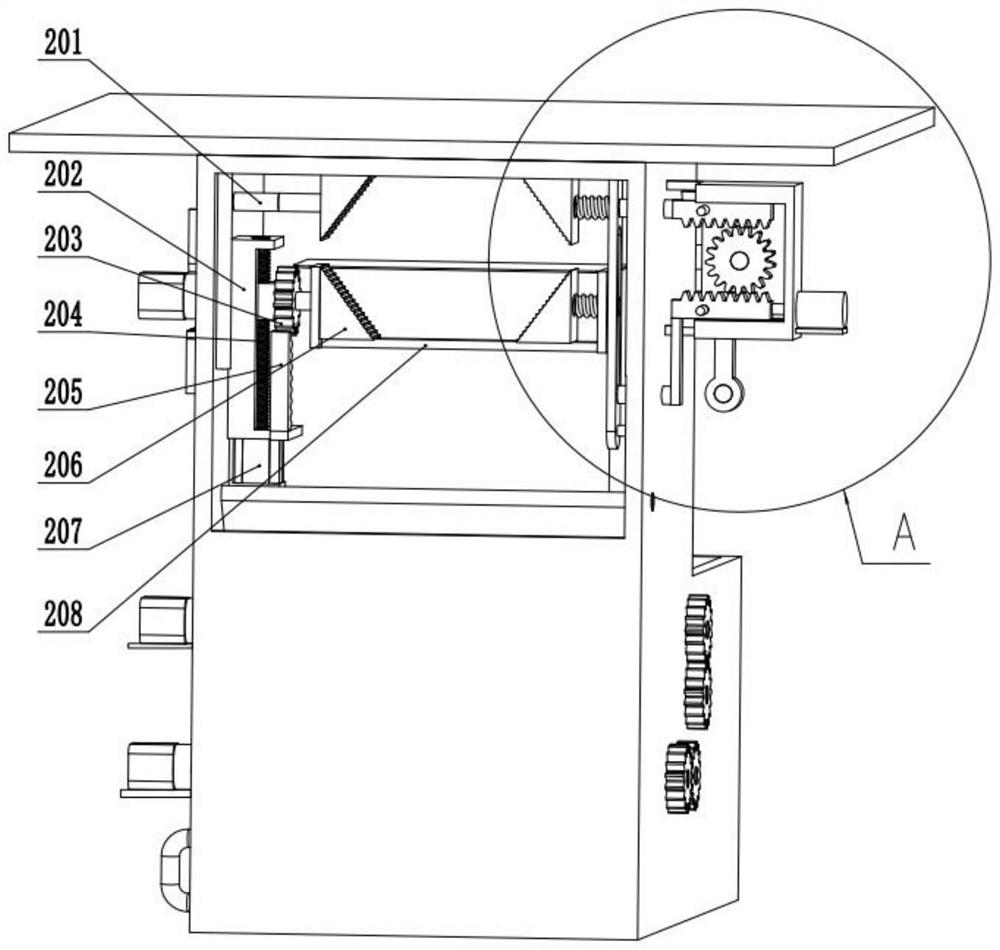

[0026] The blanking mechanism 2 is provided with a clamp block support rod 201 and a screw support seat 202 fixedly installed on the box body 101, the clamp block support rod 201 is provided with a clamp block 206, and the lead screw support seat 202 is provided with a lead screw 204 , the lead screw 204 is threadedly connected with the nut arranged on the reversing gear 203, the reversing rack 205 is fixedly arranged on the lead screw support base 202, the steering motor 207 is arranged below the lead screw support base 202, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com