Turbine blade sealing tooth machining clamp and clamping method thereof

A technology for turbine blades and sealing teeth, applied in the field of turbine blade sealing teeth processing fixtures and their clamping, can solve problems such as deformation and easy generation of chatter, increase system stiffness, solve high defect rate, avoid chatter and other problems. deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

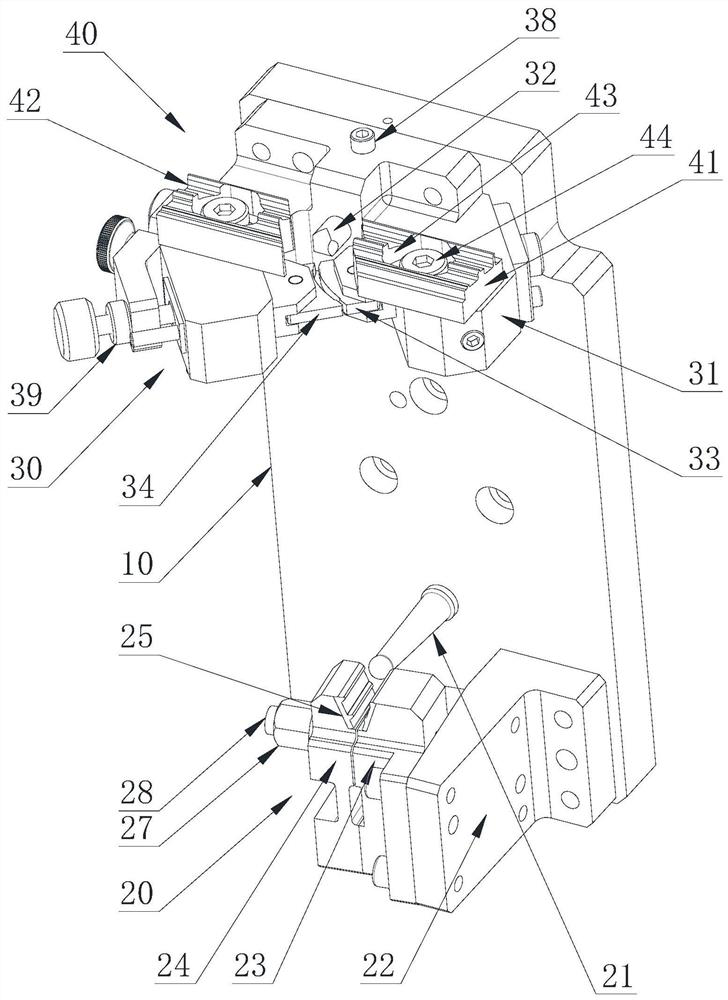

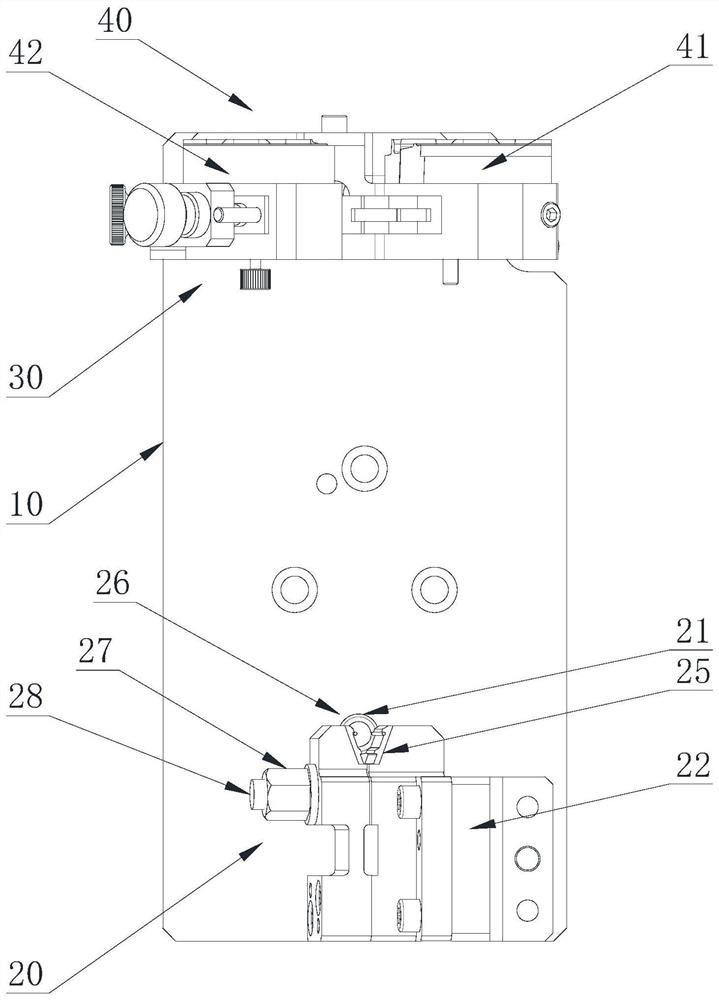

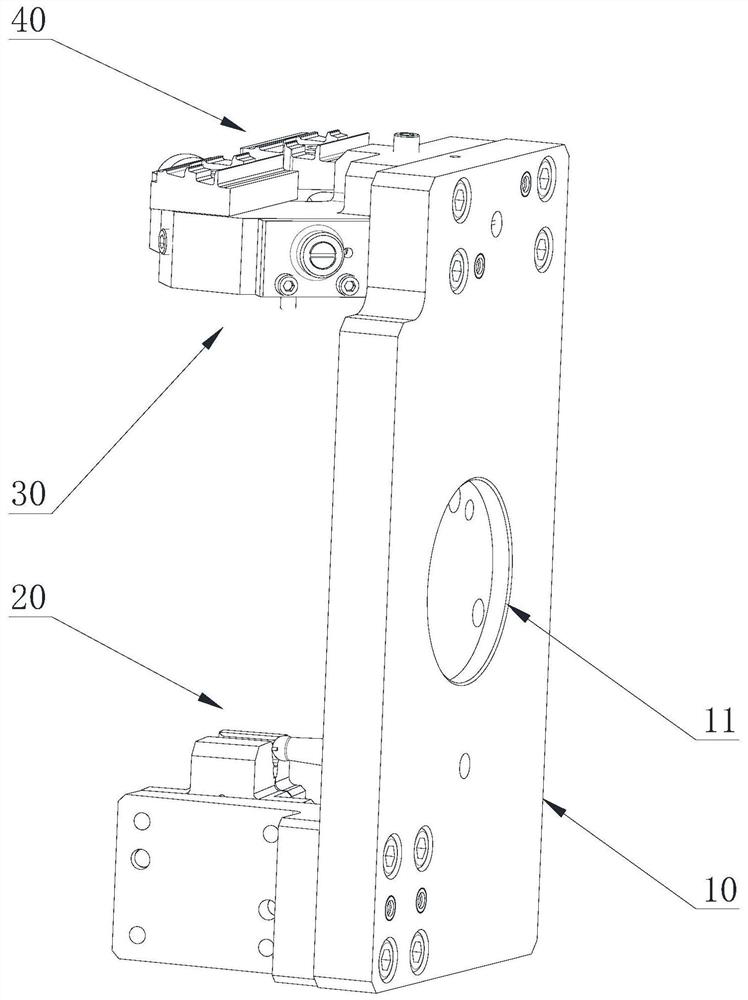

[0048] refer to figure 1 , a turbine blade sealing tooth machining fixture and its clamping method, comprising: a base 10 and a tenon clamping assembly 20 , a blade tip clamping assembly 30 and a blade shroud clamping assembly 40 respectively arranged on the base 10 .

[0049] refer to figure 1 with Figure 4, The base 10 is in the shape of a plate, and a plurality of threaded holes and pin holes are opened on the base 10 to facilitate the connection and fixing of various components. And the bottom surface of the base 10 is also provided with a positioning circular groove 11, and a plurality of fixing holes are provided in the positioning circular groove 11, and the integral fixture can be fixed on the work surface conveniently through the positioning circular groove 11.

[0050] refer to figure 1 with figure 2 , the tenon clamping assembly 20 is arranged on the end of the base 10, including the positioning ball 21 and the tenon seat 22 directly connected to the base 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com