Synchronizers for gearshift transmissions

A technology of synchronizing devices and transmissions, applied in clutches, couplings, mechanical drive clutches, etc., to solve problems such as uneven rotation and hum noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

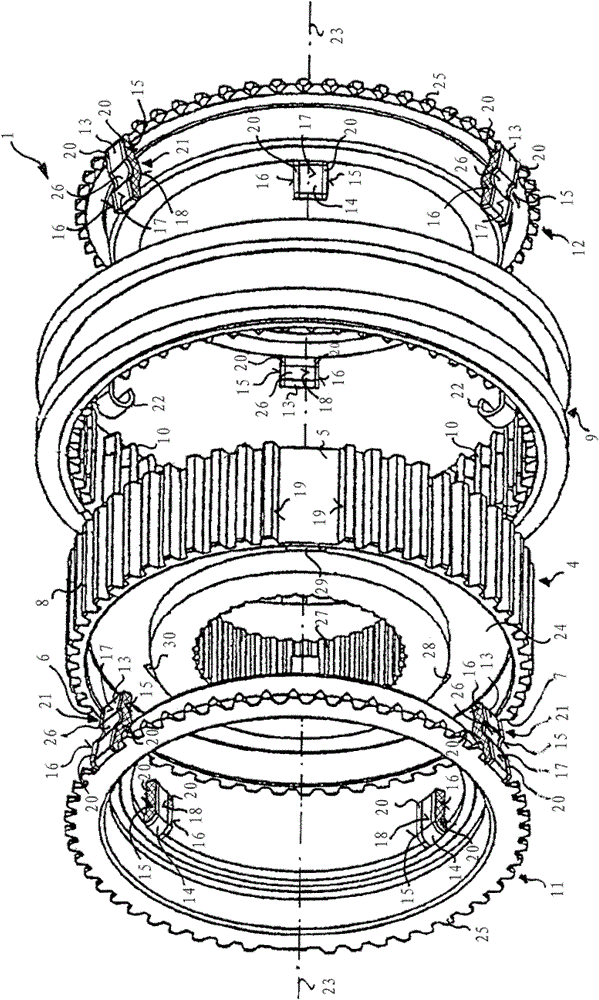

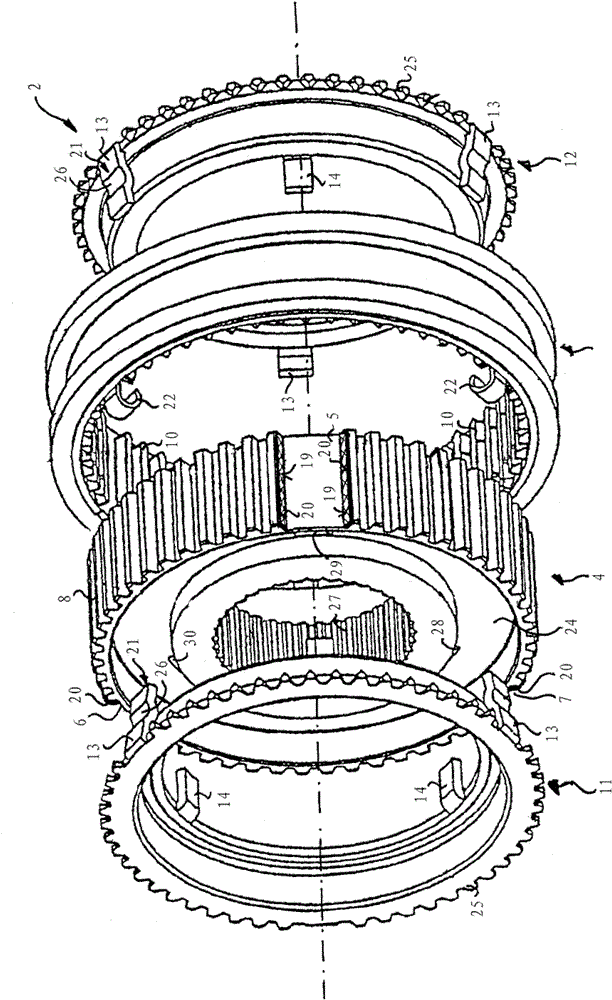

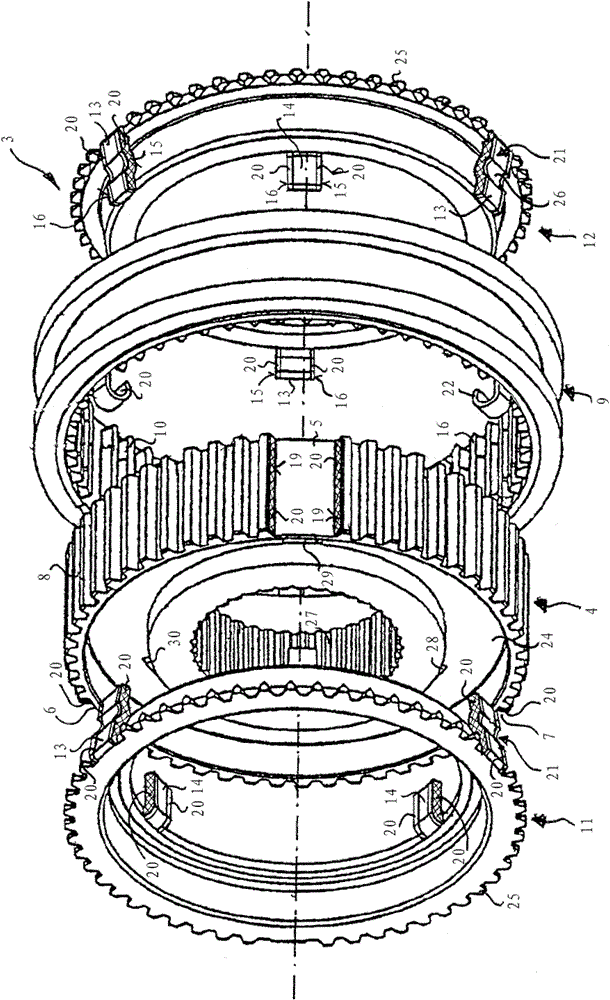

[0019] figure 1 A disassembled schematic three-dimensional schematic sketch of the synchronization device 1 according to the first embodiment of the present application is shown. The synchronizer 1 has four annular components 4 , 9 , 11 and 12 which form a double-acting synchronizer clutch or synchronizer 1 . The synchronizer housing 4 is connected in a rotationally fixed and axially fixed manner to the transmission shaft via a hub part 24 with an internal toothing 27 facing the transmission shaft axis 23 . The synchronizer housing 4 has an external toothing with three recesses 5 , 6 and 7 . The outer protrusions 13 of the synchronizing rings 11 and 12 arranged on both sides of the synchronizer housing 4 engage with the recesses 5 , 6 and 7 in a form-fitting manner.

[0020] Furthermore, in this embodiment of the application, each synchronizing ring 11 and 12 also has an inner projection 14 which engages in a form-fitting manner with corresponding recesses 28 , 29 and 30 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com