A support device for processing thin-walled parts and a processing method for thin-walled parts

A technology for thin-walled parts and a supporting device, which is applied in the field of thin-walled parts processing, can solve problems such as deformation of thin-walled parts, and achieve the effects of preventing chattering, improving machining dimensional accuracy, and high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

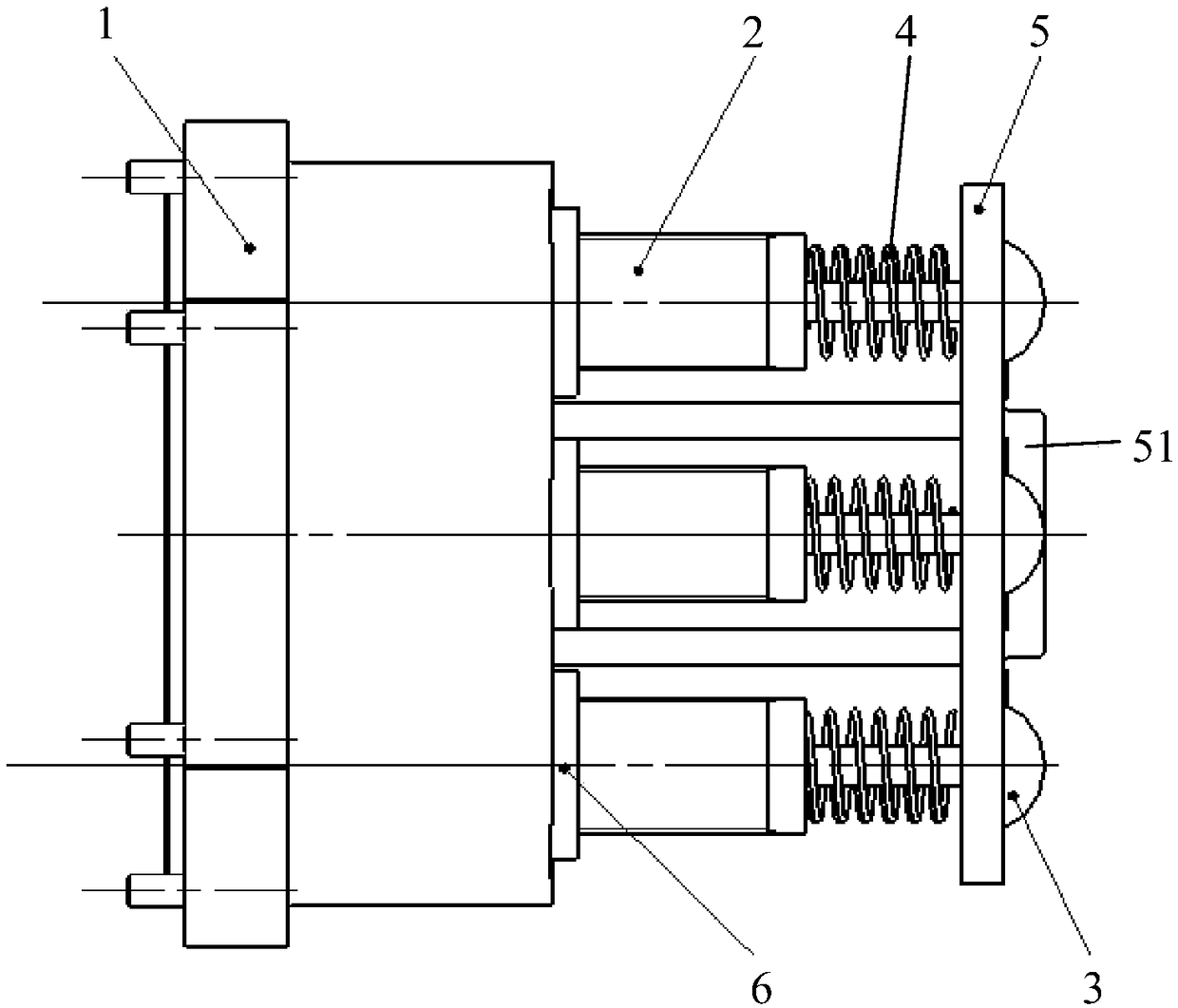

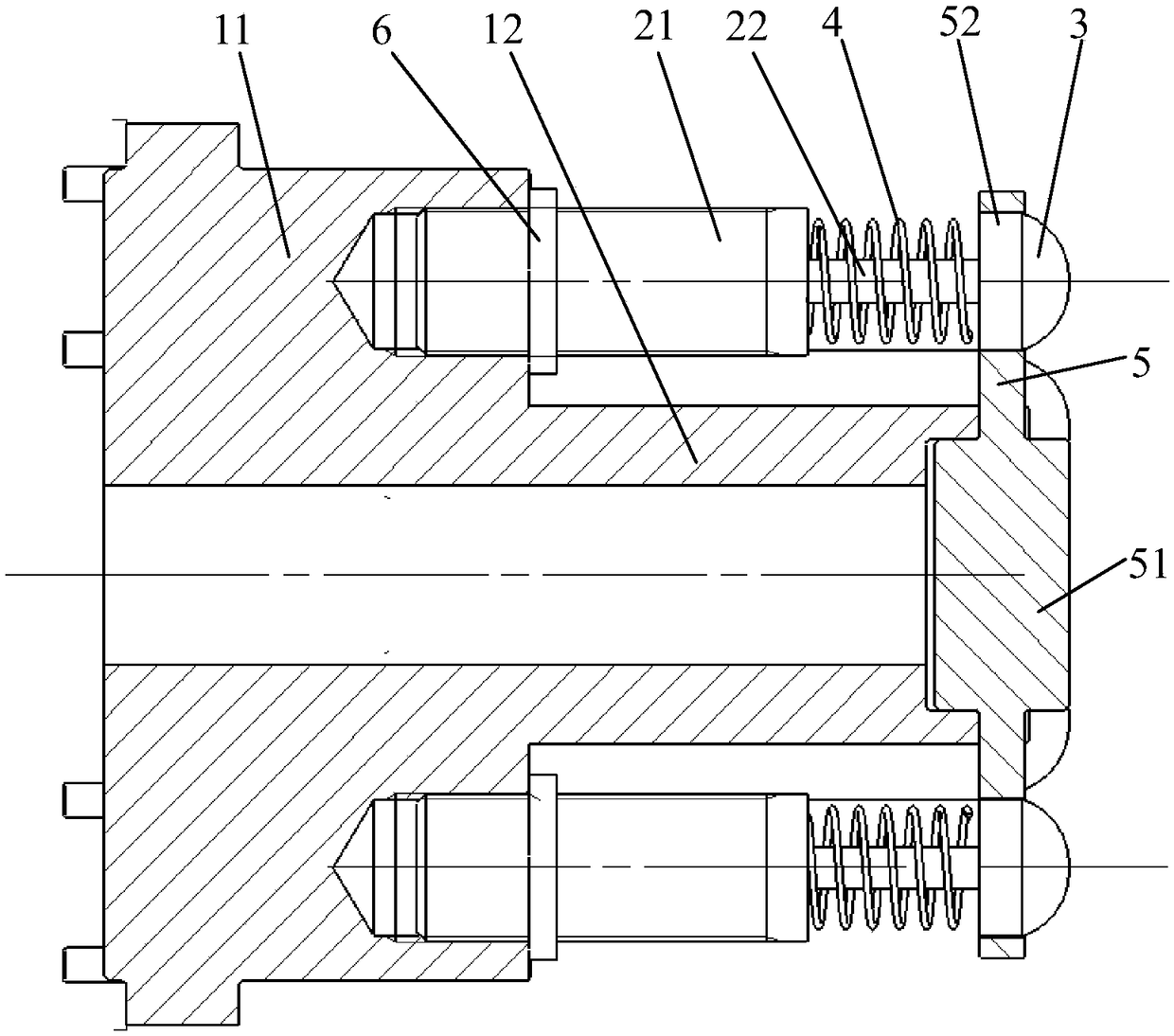

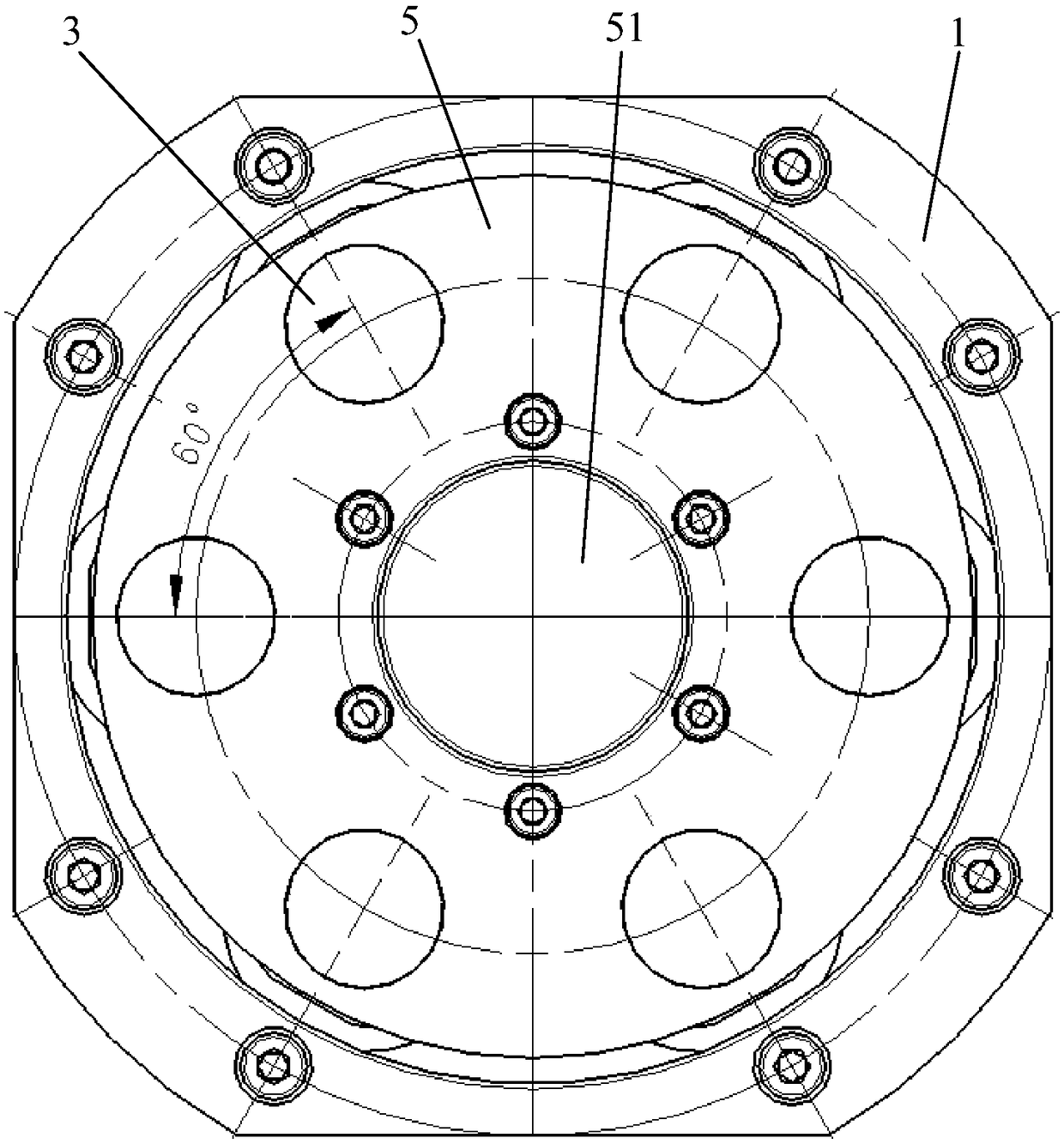

[0037] Such as figure 1 As shown, the present invention proposes a support device for processing thin-walled parts, which is used to support thin-walled sheet metal parts such as skins and automobile covers in the horizontal milling process, wherein the thickness of the aircraft skin is 2mm to 8mm, the support device of the present invention includes a mounting seat 1, a plurality of buffer devices 2 and a plurality of support members 3, the mounting seat 1 is disc-shaped, and can also be called a mounting plate, which is the main mechanical support body of the supporting device. A buffer device 2 is installed on the mounting base 1, and is arranged at intervals along the circumference of the mounting base 1; a plurality of suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com