An integrated pouring device for urban pipe gallery

A pipe gallery and urban technology, applied in the field of concrete formwork, can solve the problems of increased time spent, different formwork shapes, and prolonged construction time, avoiding re-fixing and installation, reducing the use of wood, and cost-effective effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

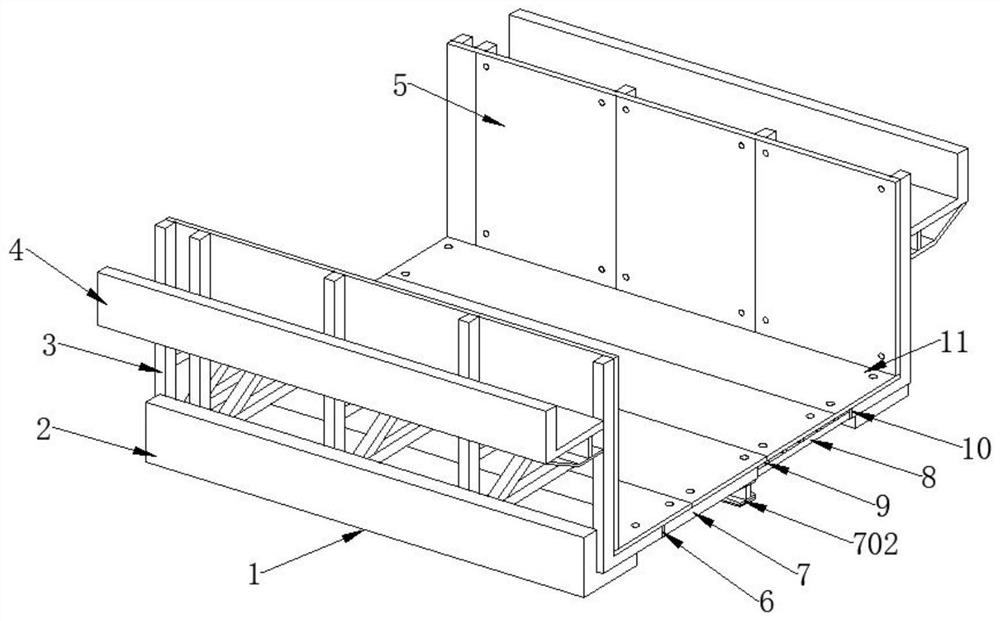

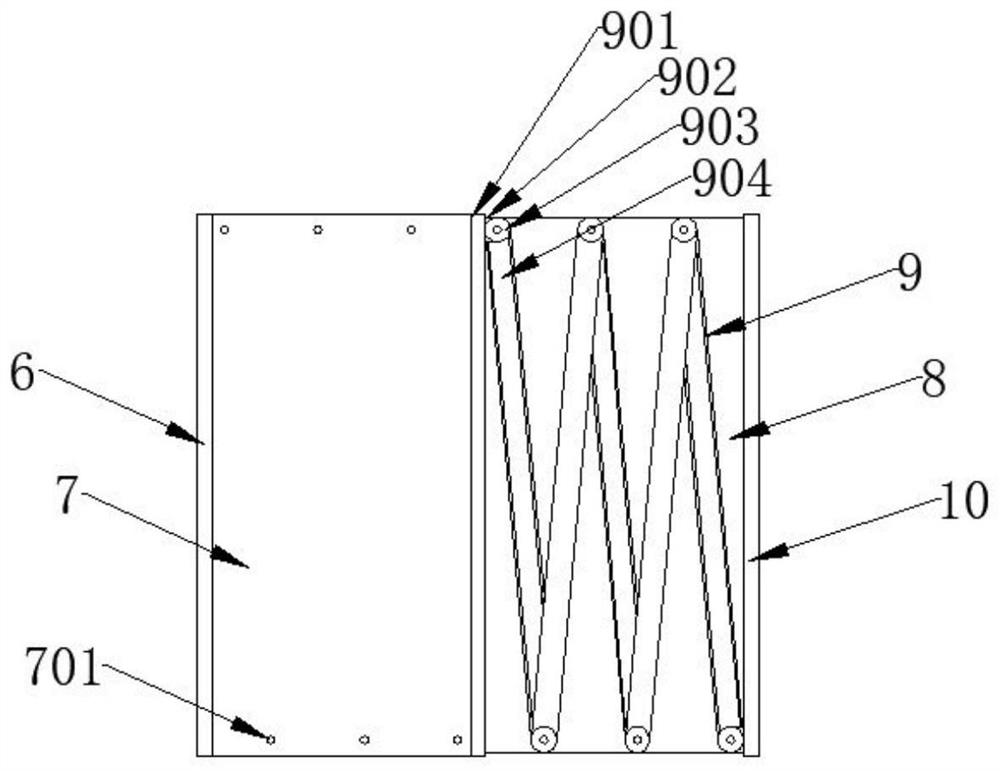

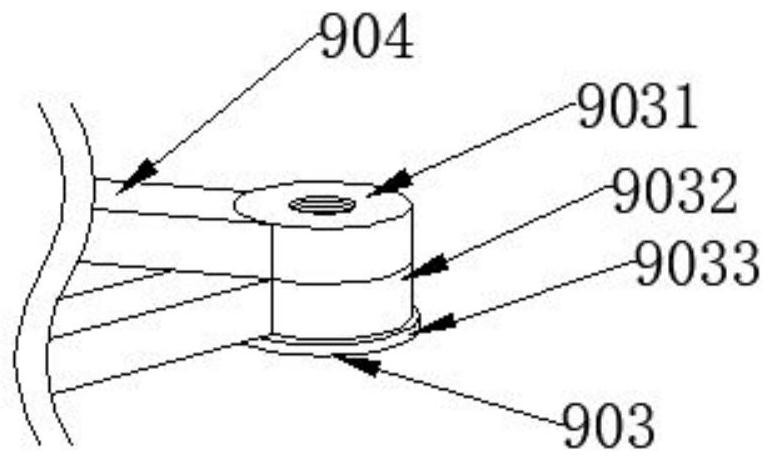

Embodiment 1

[0028] like Figure 1-6 As shown, the present invention provides an integrated pouring device for urban pipe gallery, including a pouring device main body 1, a base 2 is installed on both sides of the bottom end of the pouring device main body 1, a support frame 3 is installed on the inner side of the base 2, and the support frame 3 is installed on the inner side. A standing frame 4 is installed on the outer surface of the middle part, a side fixing plate 5 is installed on the inner wall surface of the support frame 3, a first side fixing bar 6 is installed on the inner bottom end of the support frame 3, and one end of the first side fixing bar 6 is installed with a bottom fixing plate. Plate 7, a movable plate 8 is installed on one end of the bottom fixed plate 7, a telescopic rod 9 is installed on the surface of the movable plate 8, a second side fixing strip 10 is installed at one end of the movable plate 8, and the inner bottom end of the side fixing plate 5 is installed wi...

Embodiment 2

[0041] The bottom end of the bottom fixed plate 7 is provided with a concrete seat 706 , and the top surface shape of the concrete seat is set corresponding to the fixed plate and the movable plate 8 , and other structures are the same as those of the first embodiment.

[0042] The overall structure is mainly placed on the concrete base 706, which is convenient for the force support of the bottom structure, and its load force can be distributed to the ground more evenly. structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com