Word plate shearing and adhesive tape pasting equipment and using method thereof

A technology for sticking tape and brand name, applied in the field of brand cutting and sticking tape equipment, can solve the problems that manual operation cannot guarantee the uniformity and stability of installation, low work efficiency, etc., to reduce the pulling strength and occupational disease risk, reduce labor cost, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

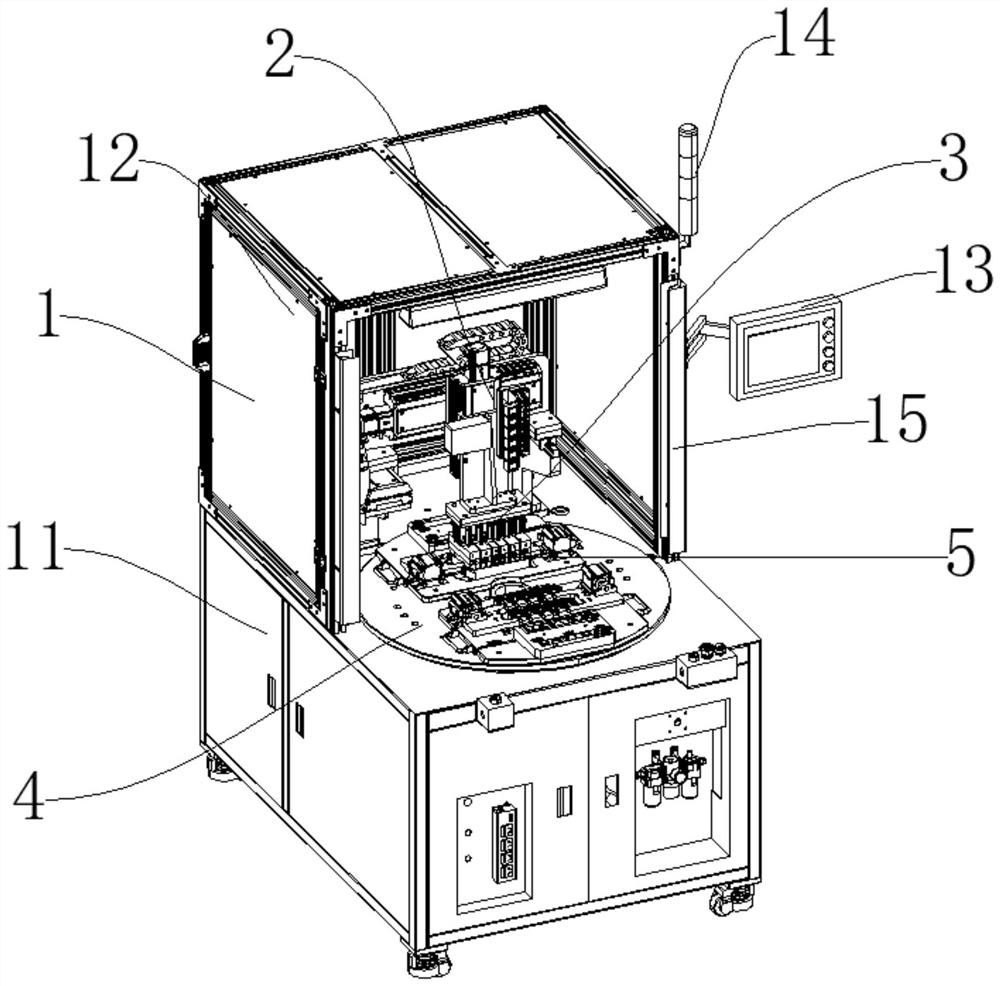

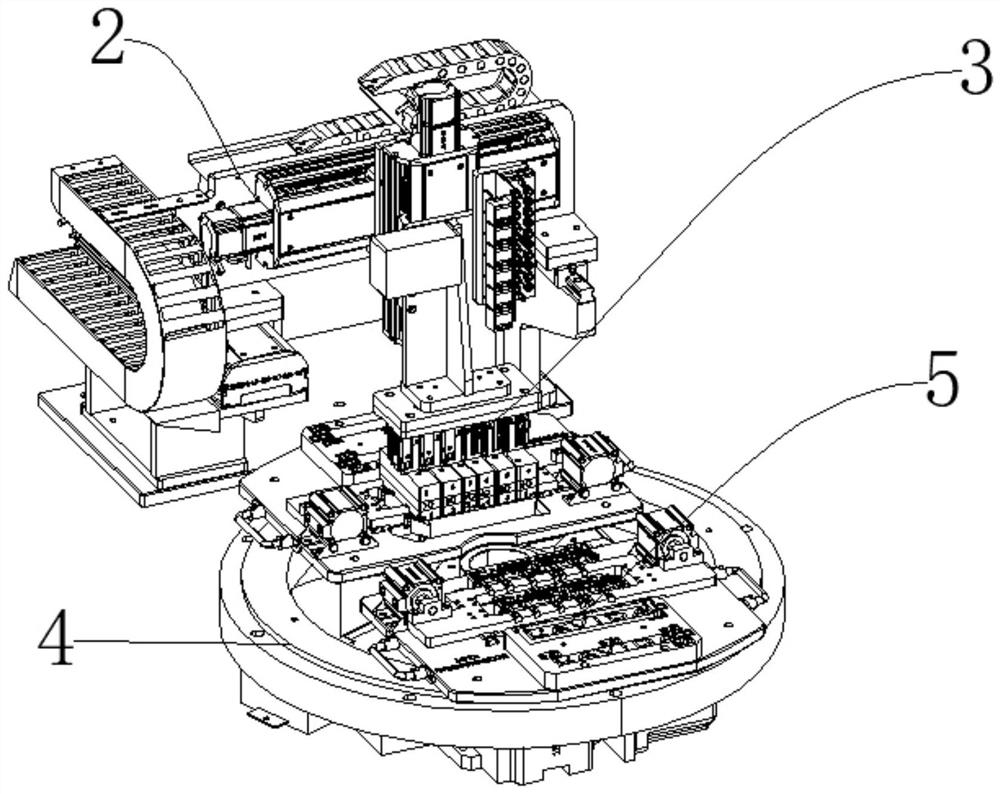

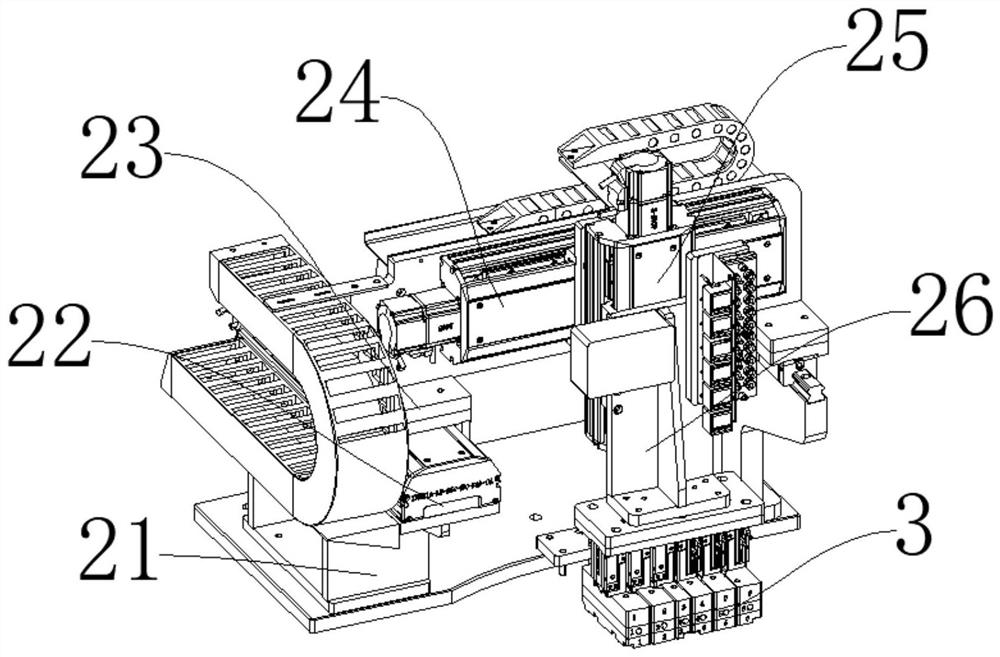

[0053] Such as Figure 1-Figure 10 As shown, the nameplate cutting and pasting tape equipment includes a placement mechanism 5 for fixing nameplates, an adsorption mechanism 3 for processing nameplates, a rotating mechanism 4, and a moving mechanism 2 that provides activity. The front end of the moving mechanism 2 An adsorption mechanism 3 is installed, the lower end of the adsorption mechanism 3 is provided with a rotation mechanism 4, two sets of placement mechanisms 5 are installed on the rotation mechanism 4, and the support mechanism 1 is connected to the outside of the moving mechanism 2;

[0054] The support mechanism 1 includes a sheet metal frame 11, a PC board cover 12, a touch screen 13, and a warning light 14. A PC board cover 12 is installed on the upper end of the sheet metal frame 11, and a safety grating 15 is arranged on both sides of the front end of the PC board cover 12. The safety grating 15 is provided with a touch screen 13 on one side, and a warning lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com