A mahogany furniture processing production line

A mahogany furniture and production line technology, applied in the field of wood processing, can solve the problems of low processing efficiency and high labor intensity, and achieve the effect of improving processing efficiency and reducing pulling strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

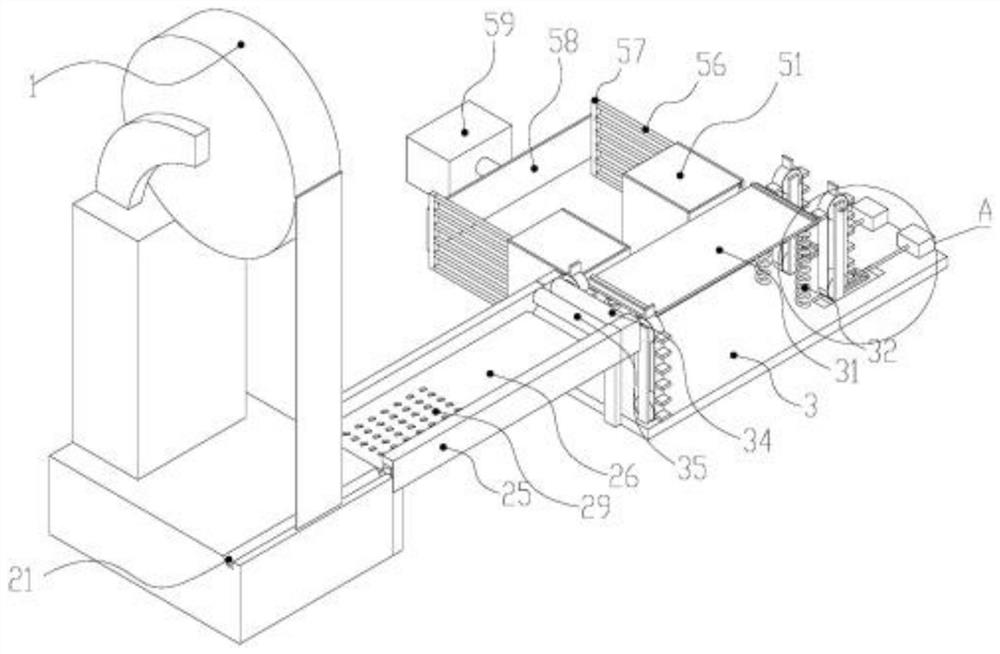

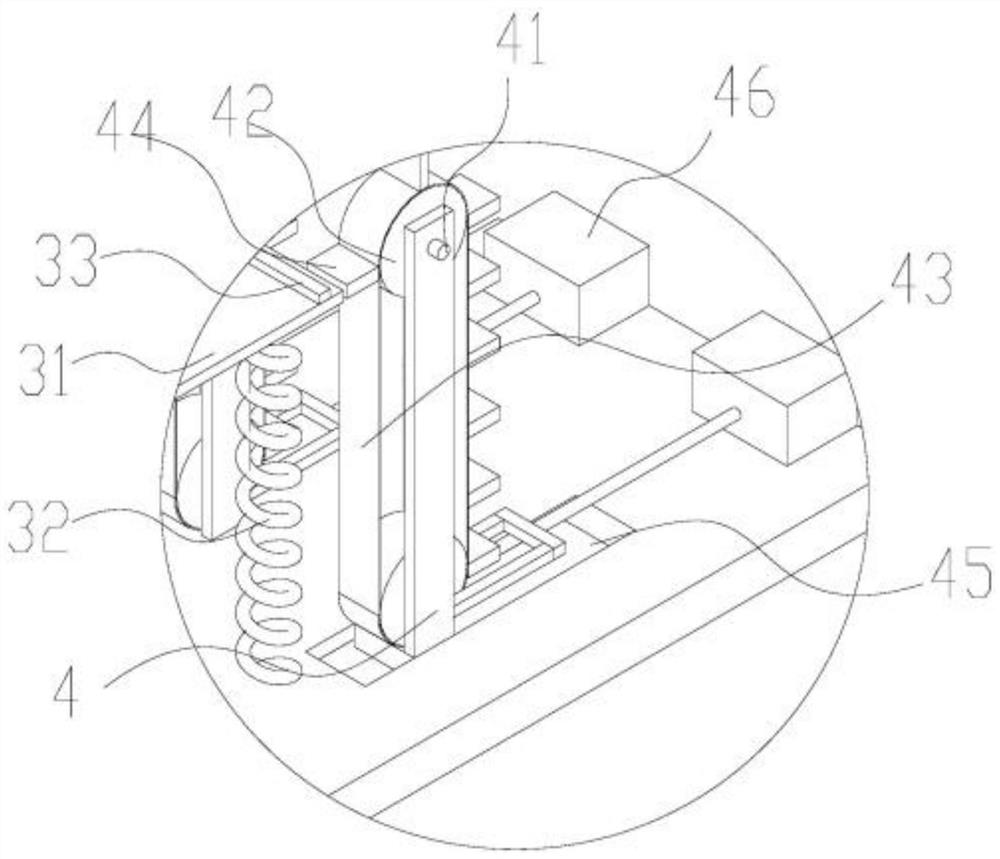

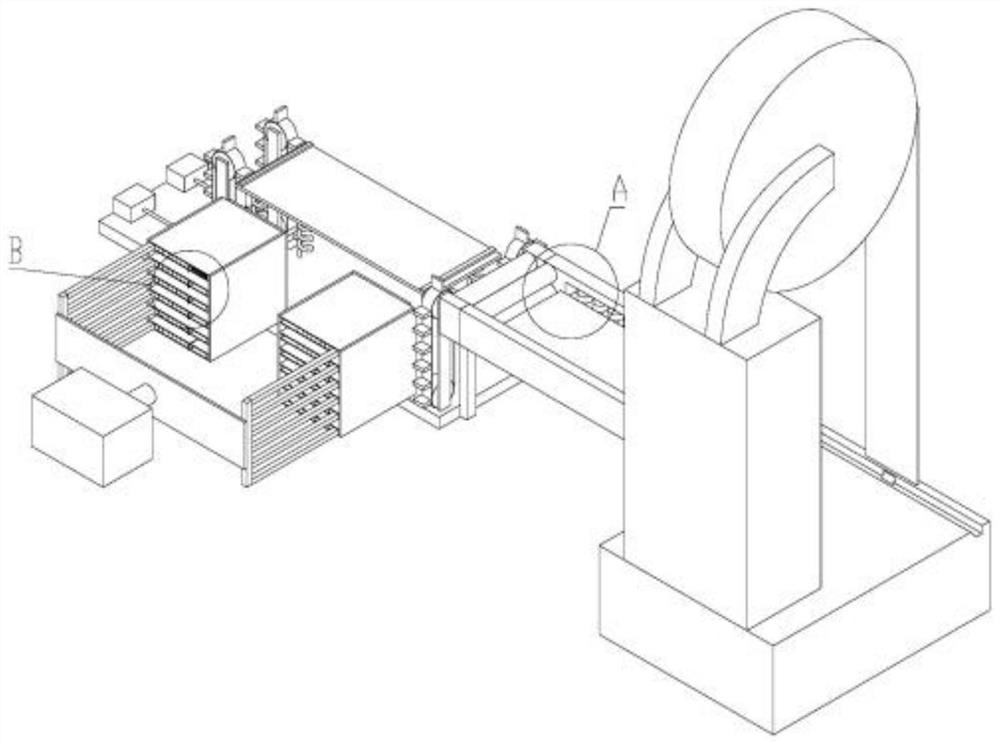

[0020] Such as Figure 1-8 As shown, a mahogany processing production line includes a cutting part 1, a conveying device, a separating device and a drying device. The cutting part 1 is a conventional band saw machine for cutting wood, and the conveying device includes a regulating Assemblies and transportation assemblies, the adjustment assembly includes a groove 21, a first installation groove 22, a push block 23 and a first elastic member 24, the groove 21 is provided on the workbench of the cutting member 1, and is located at Below, the groove 21 is provided with an inclined surface and a vertical surface, and the width of the groove gradually decreases from top to bottom, and the planks falling into the groove will automatically fall under the guidance of the inclined surface, which is convenient for transportation; A mounting groove 22 is opened on the vertical surface of the groove 21, and the push block 23 can slide relative to the first mounting groove 22. The first el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com