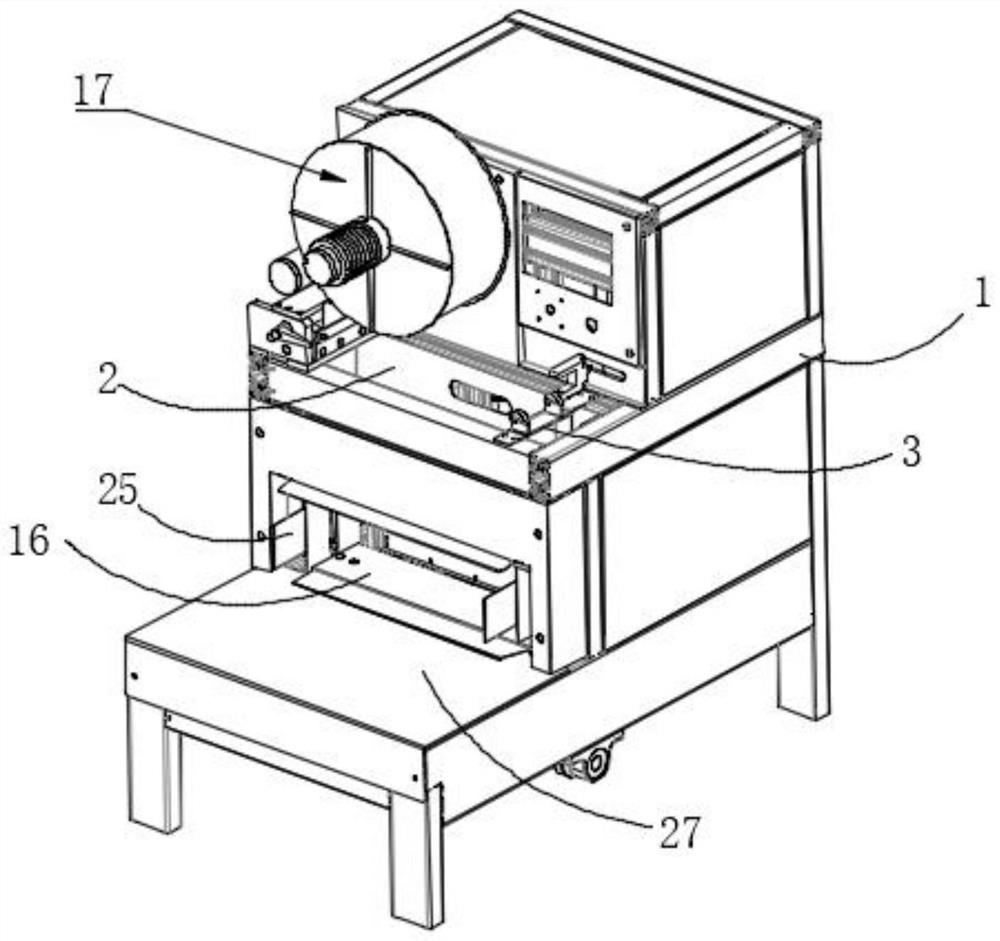

Automatic number plate boxing method and device

An automatic packing and number plate technology, applied in the direction of automatic packaging control, packaging, packaging protection, etc., can solve the problems of low work efficiency, time-consuming and laborious, and achieve the effect of improving efficiency, improving conveying efficiency, and reducing pulling strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

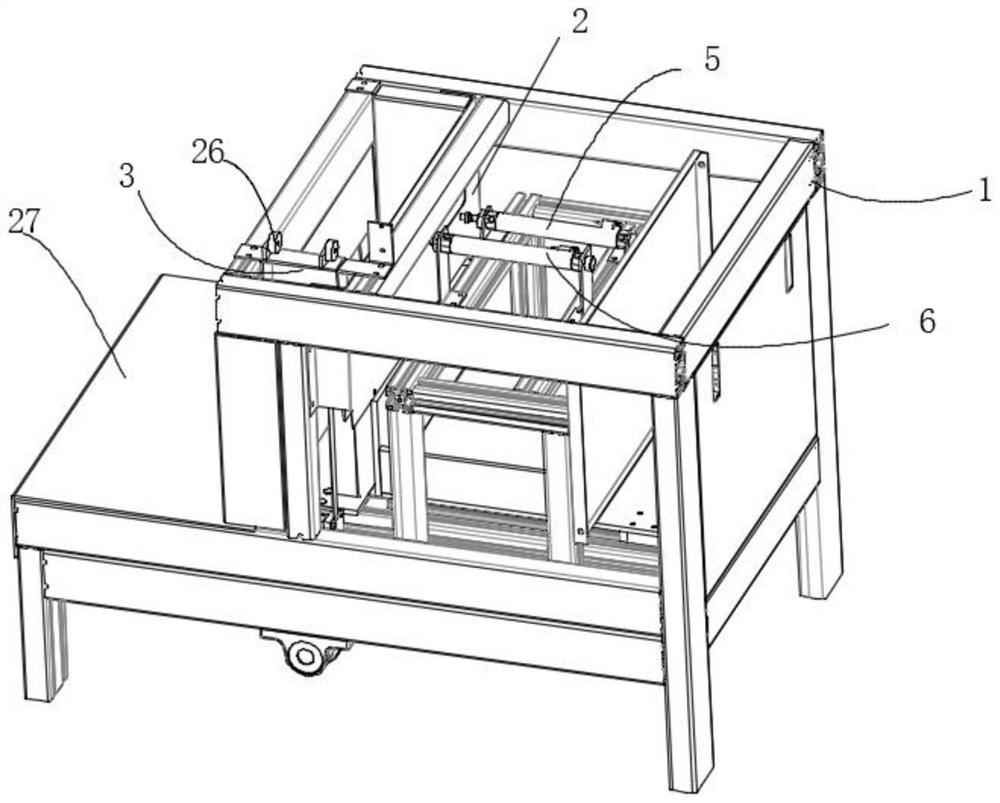

[0032] Embodiment: the number plate automatic boxing method is specifically carried out according to the following steps:

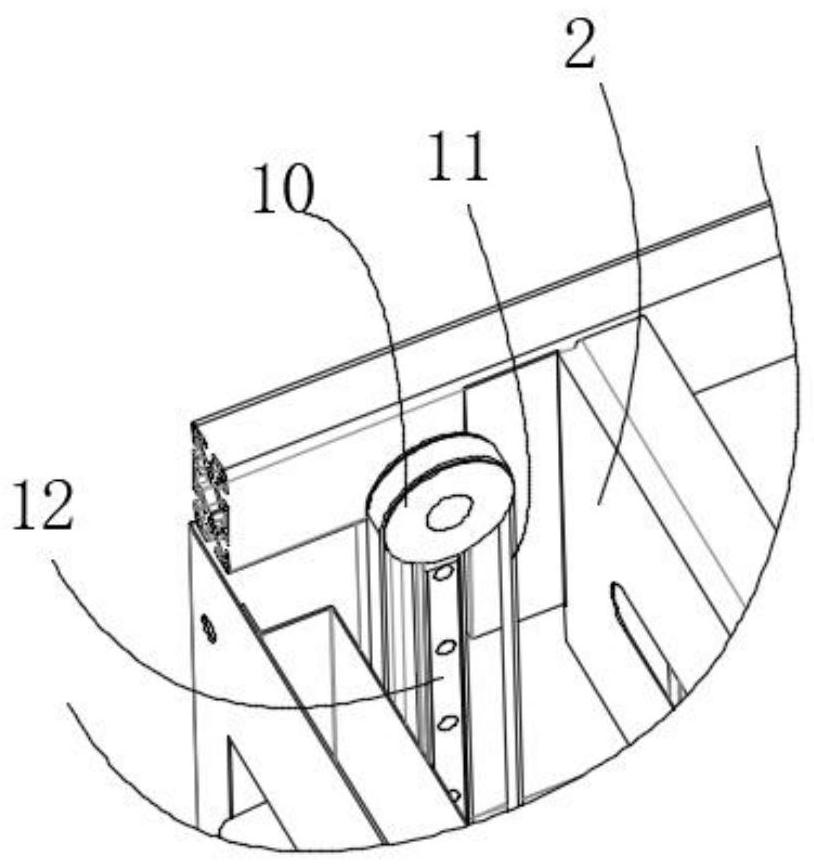

[0033] S1: The number plate is sent from one side of the main frame between the baffle plate and the number plate baffle. One end of the plate is closely attached to the number plate baffle on one side, and then the second stopper cylinder is retracted, and the number plate is tilted to the other side; S2: The paper insertion mechanism is activated, and the paper insertion motor is activated, driving the second press glue The roller rotates, and then drives the first paper pressing rubber roller to rotate, and the two rubber rollers drive the paper forward. When the length of the extended paper reaches the appropriate length, the paper insertion motor stops working, and the extended end of the paper cutting cylinder extends downward. Press against the floating joint, the movable knife swings downward to cut the paper, then the extended end of the paper cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com