Rock burst prevention rescue escape trolley based on drilling and blasting method and using method

A drilling and blasting method and rockburst technology, applied in the field of underground engineering, can solve problems such as threats to the life safety of workers, large geological detection errors, and difficulty in predicting rockburst time, etc. area and the effect of increasing the protection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

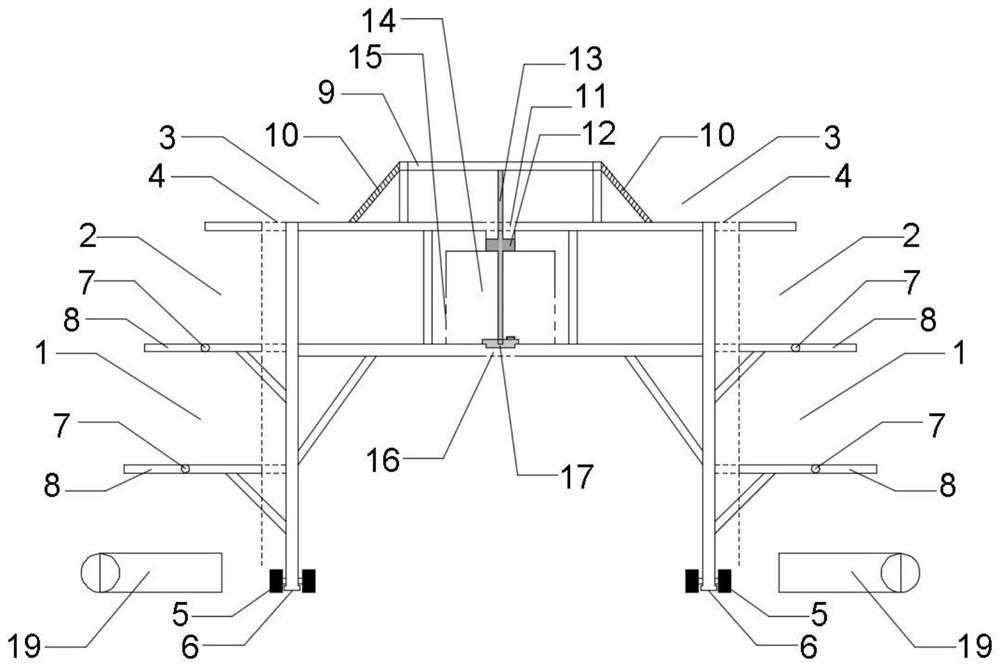

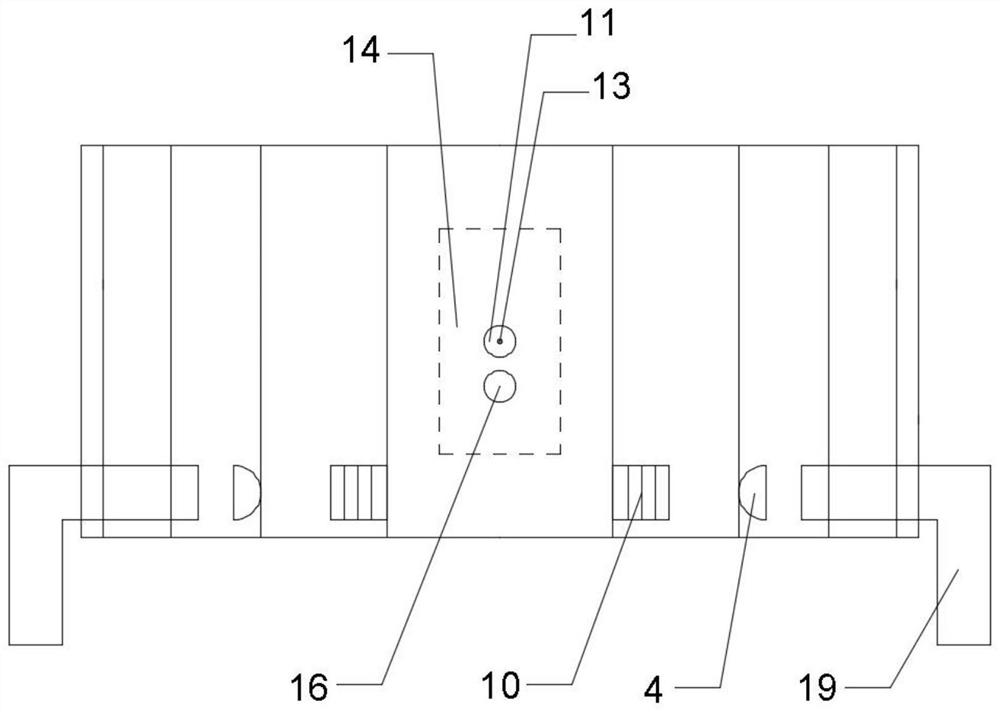

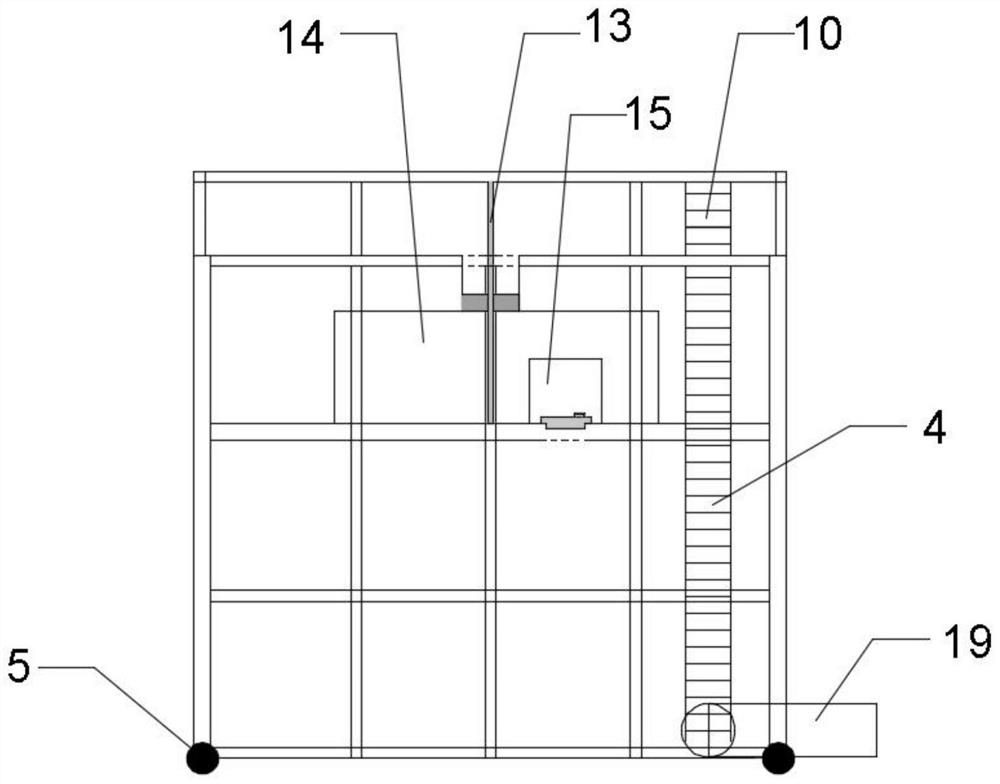

[0043] Such as Figure 1-4As shown, this embodiment provides a rockburst prevention and escape trolley based on the drill and blast method, which includes three parts, namely, the basic frame, the lifesaving protection frame and the escape protection frame. The basic framework mainly includes a three-layer truss structure formed by I-beam welding, vertical ladders (4) and liftable hydraulic tires (5), and the truss structure has a first layer of working surface (1), a second layer of working surface ( 2), the third layer of working face (3), the board surface of the third layer of working face is laid by steel plates, and each steel plate is provided with a straight ladder avoidance hole; A pressure-bearing base (6) is provided; the life-saving protection framework mainly includes a hydraulic rotating rod (7), a protective steel plate (8), a roof panel (9), a life-saving hole (11), a rubber pad (12), a life-saving rod (13), rescue cabin (14), described hydraulic rotating rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com