Liquid volume quantifying device

A quantitative device and liquid volume technology, which is applied in the direction of measuring devices, liquid/fluid solid measurement, volume measuring instruments/methods, etc., can solve the problems of inability to achieve accurate quantification, die-casting products cannot be demoulded smoothly, excessive stock solution, etc., to avoid Quantitative inaccurate problem, improve the efficiency of quantitative discharge, and ensure the effect of quantitative accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

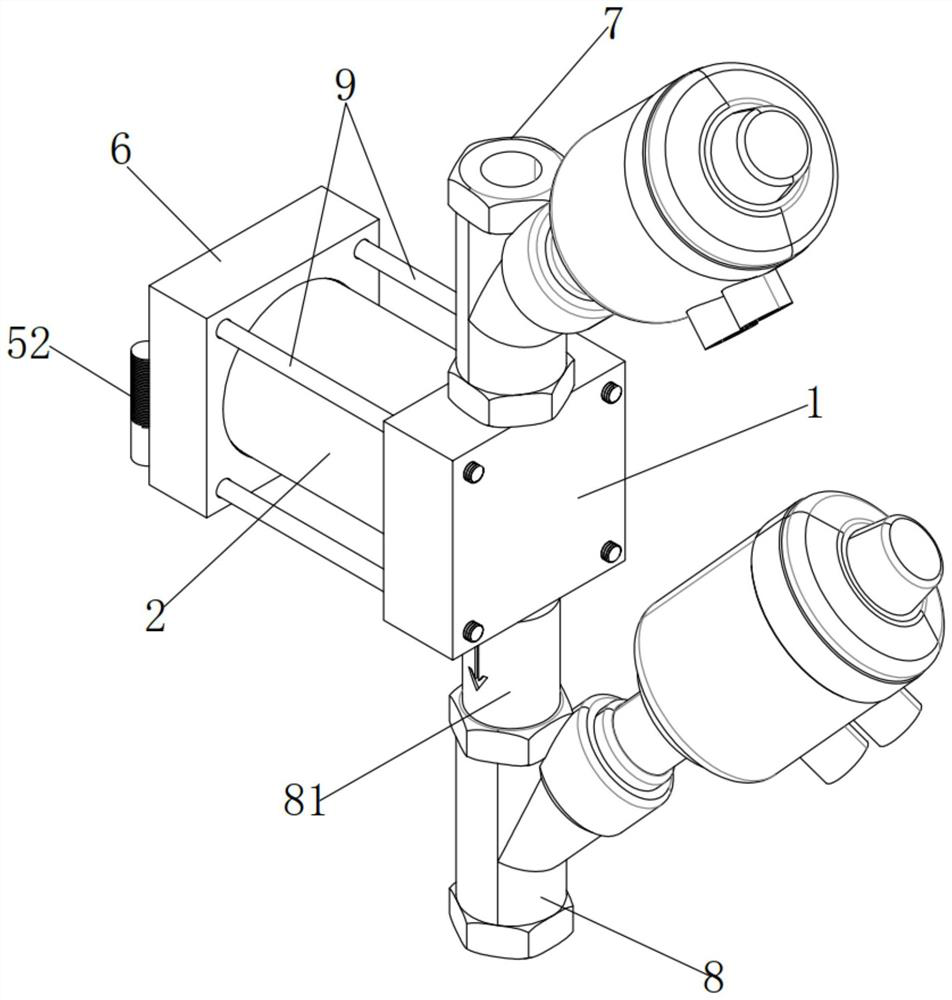

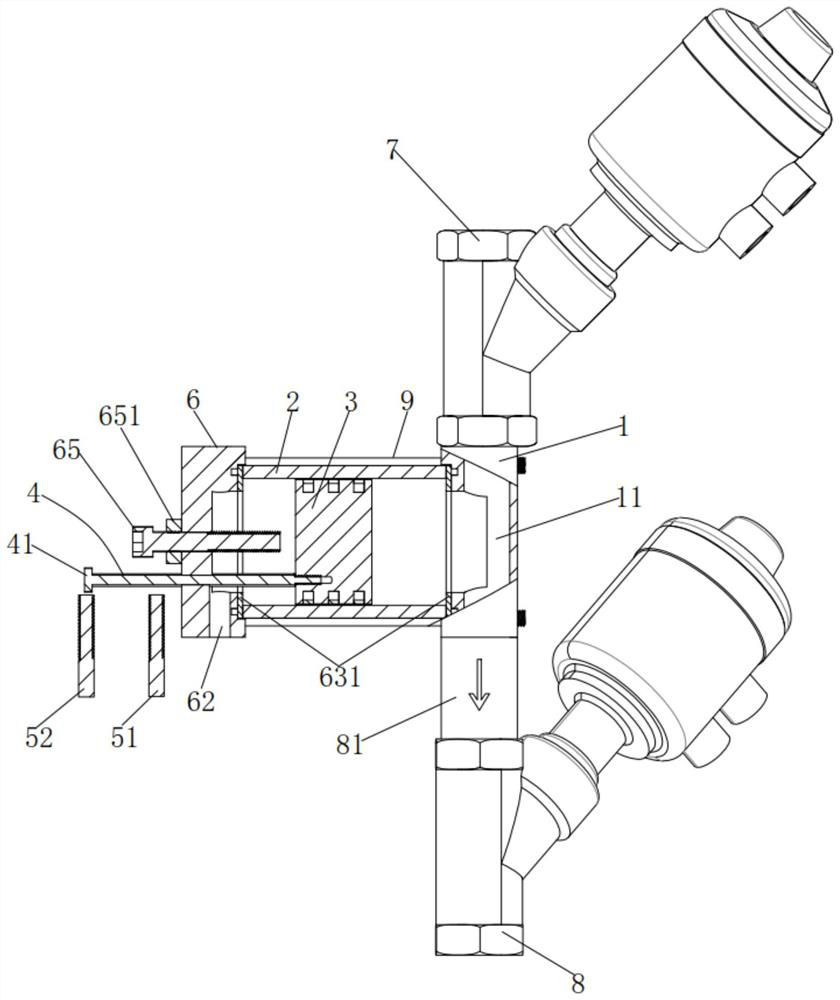

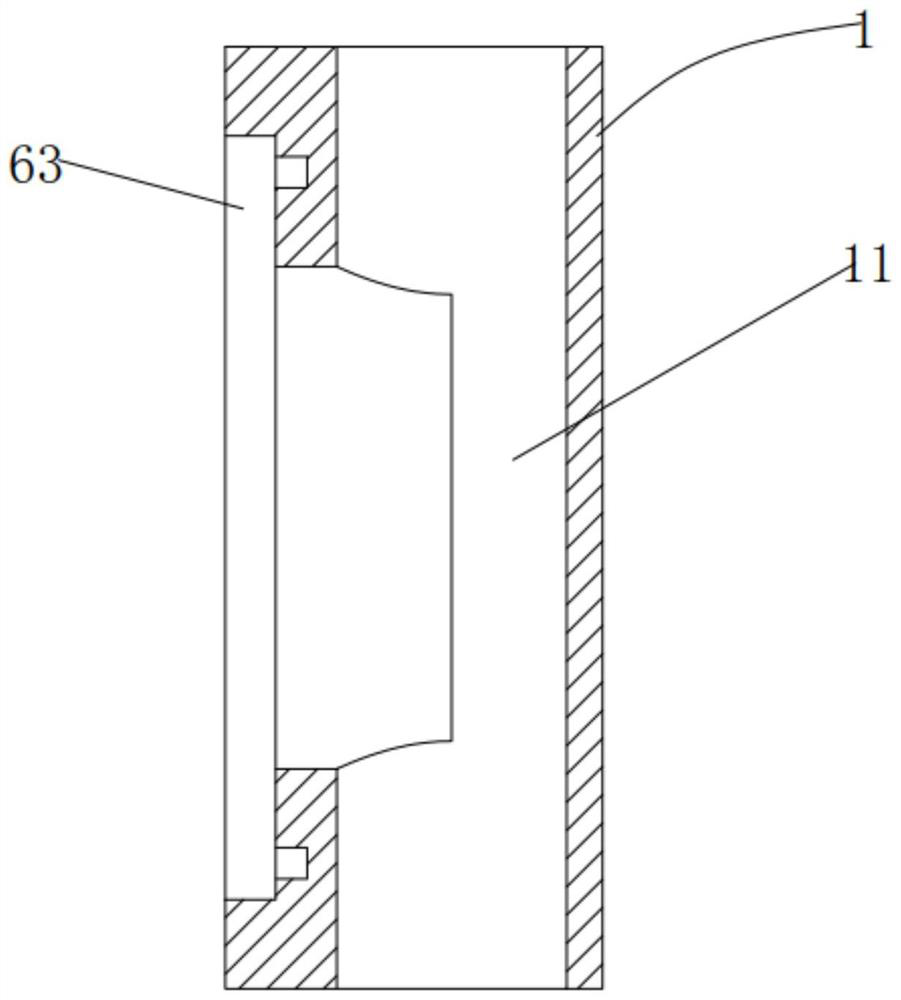

[0031] like figure 1 , figure 2 As shown, the present invention provides a liquid volume quantitative device, comprising a first base 1, a quantitative cylinder 2, a piston 3 and a second base 6, the quantitative cylinder 2 has a first end and a second end, and the quantitative cylinder 2 has a first end and a second end. The first end is set on the first base 1, and the second end of the quantitative cylinder 2 is set on the second base 6; the first base 1 is provided with a liquid inlet communicated with the raw liquid supply device, and a The liquid outlet for conveying the raw liquid, and the liquid inlet is connected with the liquid outlet to form a fluid channel 11; the fluid channel 11 is connected with the interior of the quantitative cylinder 2; the liquid inlet is provided with a liquid inlet valve 7, and the liquid outlet is provided with a liquid outlet Valve 8; the piston 3 is movably arranged in the quantitative cylinder 2, and the outer circumference of the pi...

no. 2 example

[0040] like figure 1 , figure 2 As shown, the present invention provides a liquid volume quantitative device, comprising a first base 1, a quantitative cylinder 2, a piston 3 and a second base 6, the quantitative cylinder 2 has a first end and a second end, and the quantitative cylinder 2 has a first end and a second end. The first end is set on the first base 1, and the second end of the quantitative cylinder 2 is set on the second base 6; the first base 1 is provided with a liquid inlet communicated with the raw liquid supply device, and a The liquid outlet for conveying the raw liquid, and the liquid inlet is connected with the liquid outlet to form a fluid channel 11; the fluid channel 11 is connected with the interior of the quantitative cylinder 2; the liquid inlet is provided with a liquid inlet valve 7, and the liquid outlet is provided with a liquid outlet Valve 8; the piston 3 is movably arranged in the quantitative cylinder 2, and the outer circumference of the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com