Field management control system and method

A technology for on-site management and control systems, applied in the general control system, control/regulation system, program control, etc., can solve the problems of reduced management work efficiency, time-consuming, fast management and control, etc., and achieve management work efficiency improvement and saving Control time and manage simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

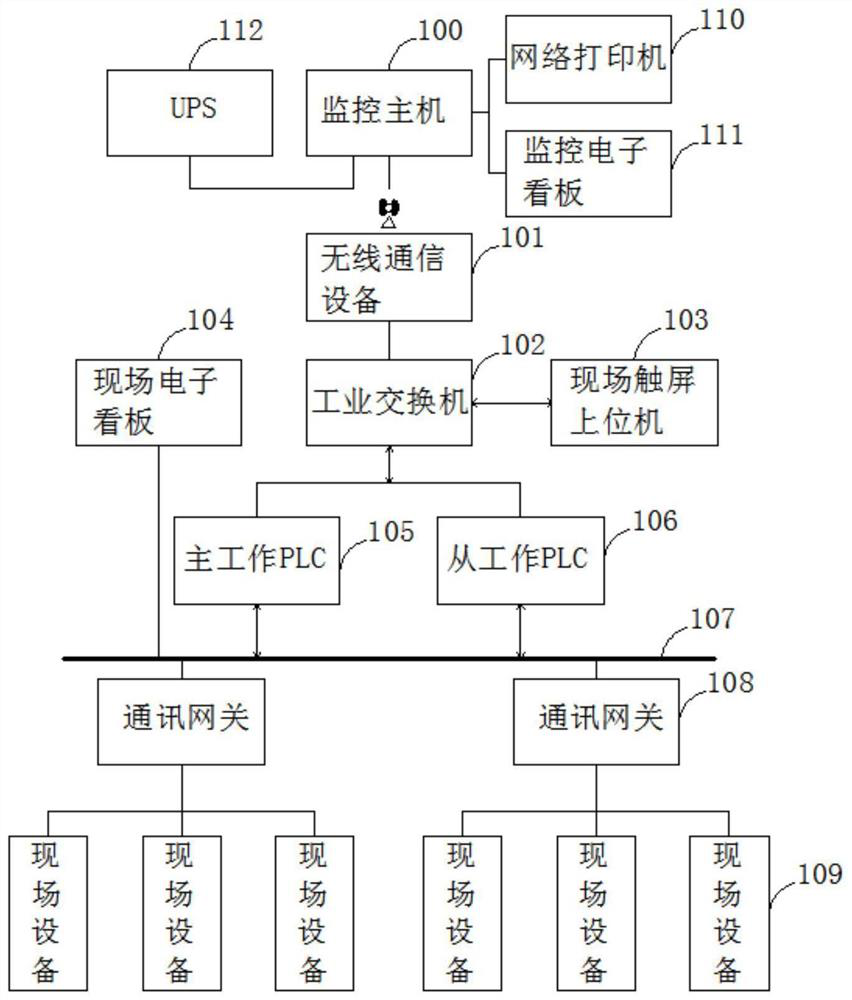

[0040] Such as Figure 1-2 As shown, the embodiment of the present invention provides an on-site management control system, including:

[0041] The industrial switch 102 is used to connect the on-site touch screen upper computer 103, the main working PLC105 and the slave working PLC106, and operate the on-site touch screen upper computer 103 to control and manage the main working PLC105 and the slave working PLC106 through the industrial switch 102;

[0042] The field bus 107 is used to connect the main work PLC105, the slave work PLC106 and at least one communication gateway 108, and is used to realize the network interconnection between the main work PLC105, the slave work PLC106 and the communication gateway 108;

[0043] The communication gateway 108 is used to connect multiple field devices 109 to realize network interconnection between multiple field devices 109;

[0044] On-site electronic kanban 104, which is connected to the field bus 107, is used to watch the visual...

Embodiment 2

[0058] An embodiment of the present invention provides a field management control method, including the following steps:

[0059] Step 1: the management personnel watches the visual control information of each field device 109 from the main work PLC105 and from the work PLC106 through the on-site electronic Kanban 104;

[0060] Step 2: when the operating status of each field device 109 needs to be changed, the management personnel carry out on-site control and management to the main work PLC105 and the slave work PLC106 through the on-site touch screen upper computer 103;

[0061] Step 3: the main work PLC105 and the slave work PLC106 cooperate to complete the change control process of each field device 109 under the control of the on-site touch screen host computer 103;

[0062] Step 4: The management personnel watch the visualized control information of each field device 109 after the main work PLC 105 and the slave work PLC 106 change control through the on-site electronic ...

Embodiment 3

[0064] The embodiment of the present invention also provides another on-site management control method, comprising the following steps:

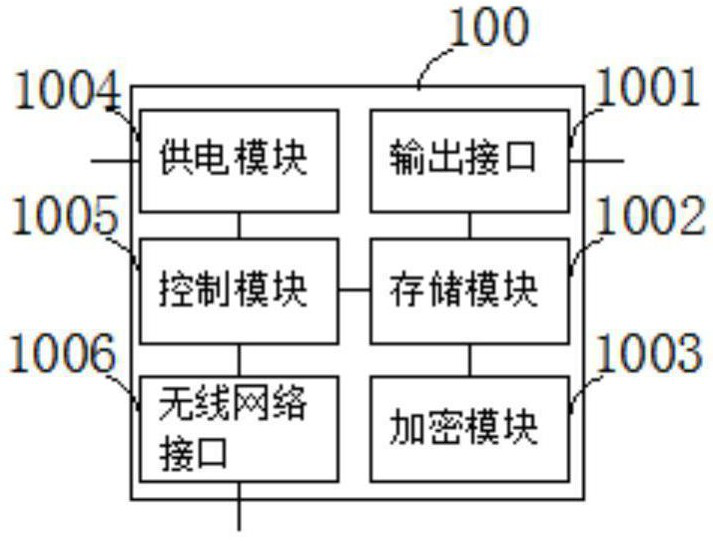

[0065] Step 1: the main work PLC105 and the visual control information of each field device 109 from the work PLC106 are sent to the monitoring host 100 by the wireless communication device 101;

[0066] Step 2: the manager logs in the monitoring host 100 by decoding the encryption module 1003, and prints the document control information or remotely watches the visualization control information through the network printer 110 or the monitoring electronic kanban 111;

[0067] Step 3: When the operating state of each field device 109 needs to be changed, the management personnel remotely control and manage the main working PLC 105 and the slave working PLC 106 through the control module 1005 of the monitoring host 100;

[0068] Step 4: the master work PLC105 and the slave work PLC106 cooperate to complete the change control process of each fie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com