Flexible splicing type aluminum substrate with high thermal conductivity

An aluminum substrate, splicing technology, applied in the structural connection of printed circuits, circuit thermal devices, printed circuit components, etc., can solve the problems of too large aluminum substrate, poor heat dissipation effect, inconvenient installation, etc., to improve thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

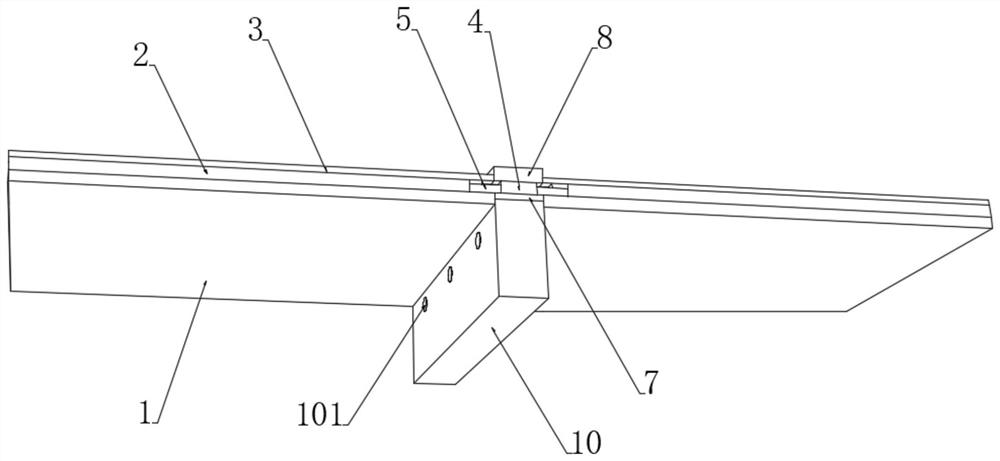

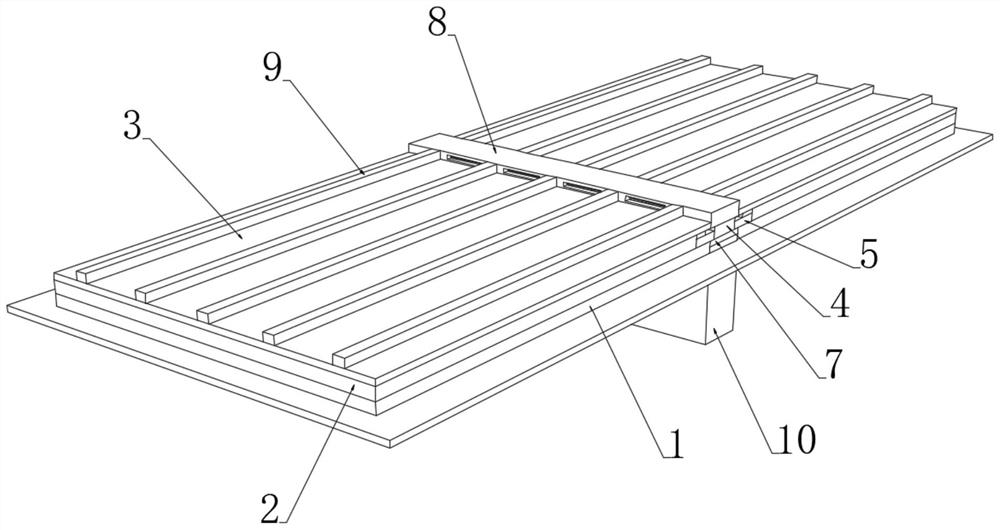

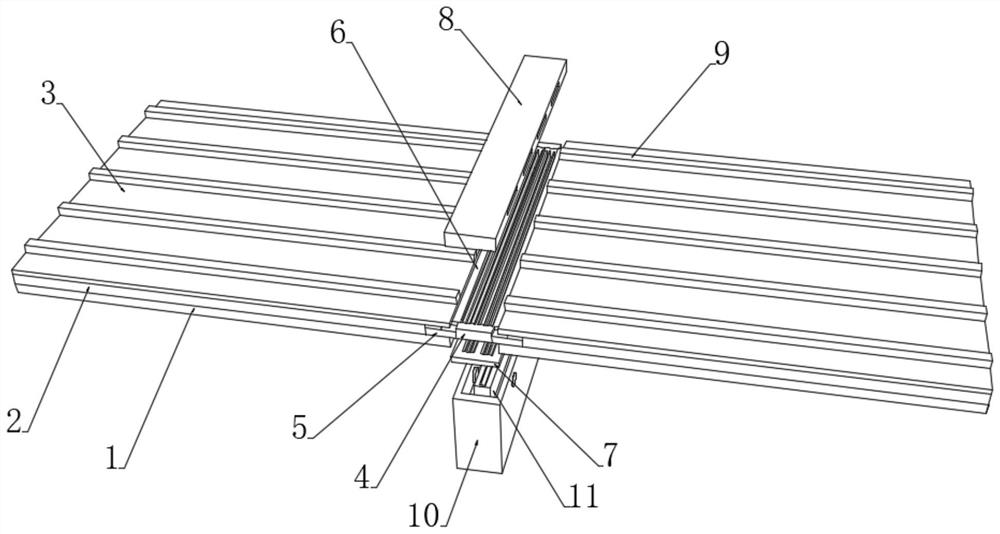

[0043] see Figure 1-2 , a flexible spliced aluminum substrate with high thermal conductivity, including a pair of aluminum substrates, the aluminum substrate includes a metal base layer 1, an insulating layer 2 and a circuit layer 3, the metal base layer 1 is installed on the board, and the circuit layer 3 passes through the insulating layer 2 and the circuit layer The metal base layer 1 transmits heat to the outside of the board, and a flexible connecting part is provided between a pair of insulating layers 2. The seat is clamped between a pair of circuit layers 3 , and the hollow air guide seat 8 , the flexible connecting portion, and the heat dissipation seat 10 are arranged in communication with each other.

[0044] see Figure 3-6 A splicing cavity is provided between the metal base layer 1 and the insulating layer 2, and the left and right ends of the flexible connecting part respectively extend into the splicing cavity and are fixedly connected with the insulating l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com